An New Batch Of Screw Conveyor Are In Production

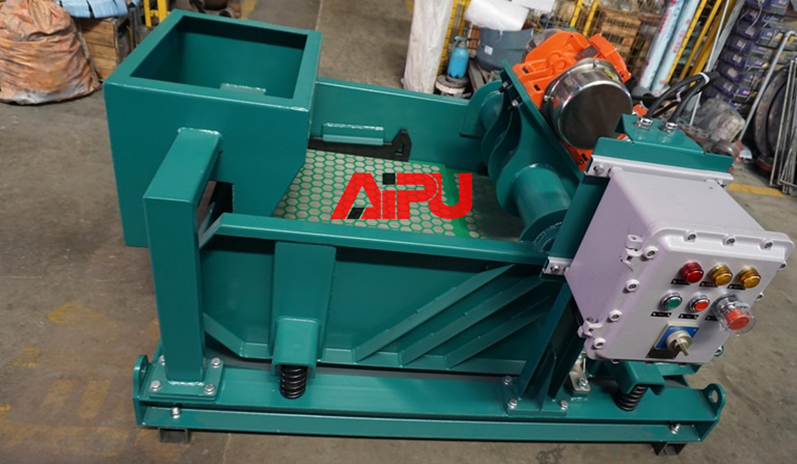

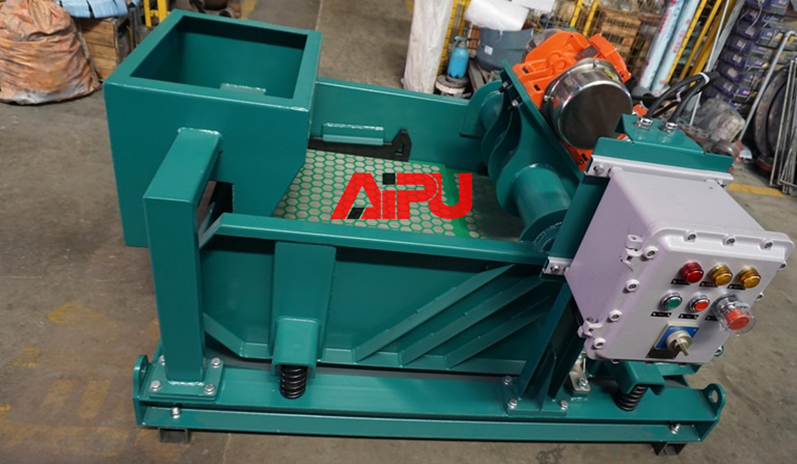

AIPU supply various kinds of shale shakers, the treating capacity from 50 to 200 cubic meters per hour for option. The customers from geothermal drilling who prefer the mini shale shaker. As mini shakers are cost-effective solutions for small-scale drilling operations, offering efficient solids separation while minimizing space and resource usage.

Specification of MINI shaker

Mini shaker application:

Mini shale shakers are beneficial in several industries where space is limited and smaller-scale drilling operations are conducted. Including geothermal drilling, water well drilling, diamond core drilling, mining and coal cleaning, horizontal directional drilling (HDD), and some environmental drilling projects, such as those involving soil remediation or groundwater monitoring, where smaller equipment is preferred.

Key features of AIPU mini shale shaker:

Compact design: Smaller size and lighter weight compared to standard shale shakers.

Linear motion: AIPU mini shakers use linear motion to separate solids from drilling fluids effectively.

Screen panels: Typically the mini shale equipped with 2 panels to handle lower flow rates. Steel frame and dimension of 750x900mm, standard size is MESH 40, that can be customized for different drilling operation.

Vibration motor: Powered by smaller vibration motors 2×0.75 kW to manage the reduced capacity. We used Italy brand OLI to make sure the stable performance and long service time.

Screen Area: We provides a smaller total screen area 1.35 m²that suitable for smaller flow rates.

What’s your drilling types? Please do not hesitate to contact AIPU for more information.

Specification of MINI shaker

| Name | Mini shale shaker for geothermal drilling rig |

| Model | Hunter mini |

| Capacity | 50 Cubic meters per hour |

| Vibration motor | 2x0.75kW |

| Shaker screens | Steel frame |

Mini shaker application:

Mini shale shakers are beneficial in several industries where space is limited and smaller-scale drilling operations are conducted. Including geothermal drilling, water well drilling, diamond core drilling, mining and coal cleaning, horizontal directional drilling (HDD), and some environmental drilling projects, such as those involving soil remediation or groundwater monitoring, where smaller equipment is preferred.

Key features of AIPU mini shale shaker:

Compact design: Smaller size and lighter weight compared to standard shale shakers.

Linear motion: AIPU mini shakers use linear motion to separate solids from drilling fluids effectively.

Screen panels: Typically the mini shale equipped with 2 panels to handle lower flow rates. Steel frame and dimension of 750x900mm, standard size is MESH 40, that can be customized for different drilling operation.

Vibration motor: Powered by smaller vibration motors 2×0.75 kW to manage the reduced capacity. We used Italy brand OLI to make sure the stable performance and long service time.

Screen Area: We provides a smaller total screen area 1.35 m²that suitable for smaller flow rates.

What’s your drilling types? Please do not hesitate to contact AIPU for more information.