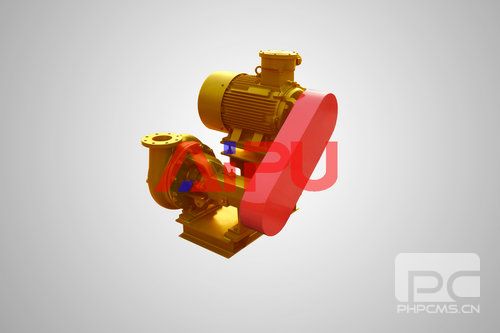

Shear pump is a new type of pump and offer fast treatment for the drilling mud. This series of shear pumps can mix effectively and hydrate completely the material added in the drilling fluid, providing the high performance mud for the well drilling.

The working principle of shear pump

The turbine axial flow provide the certain displacement flow for pump impeller and storage tank, the 50% of the liquid discharged through the pump impeller and enter into the volute casing. The other 50% liquid is absorbed by storage tank. The unique design of the pressure cabin make the liquid in storage tank have the certain energy. The liquid discharged through pump impeller parallel to the shear plate flow with the higher flow speed. The inspiratory liquid by storage tank through 44 nozzles perpendicular to the shear plate injection. The injection fluid mixed with the fluid discharged by pump impeller with higher flow speed impact the shear pump saw tooth, the high speed rotary shear plate saw tooth re-sheared the fluid. So the fluid flow through the impeller will bear many times shearing action.

Meanwhile, the use of shear pump can reduce more than 15% polymer, bentonite consumption decreased by 30%, and improved the flow of mud cake and losses, lower than the rate of drilling fluid shear, improve gel strength, reached similar foreign advanced level of products, which is more reliable seal structure, with excellent performance, easier to maintain.