Shear pump is used in a solids control system to treat the high property mud, make the mud to obtain good rheological properties quickly and cut the drilling cost as much as possible. Aipu solids control provides world-class shear pump in drilling fluids circulation system for worldwide customers such as Canada, Russian, middle east.etc.

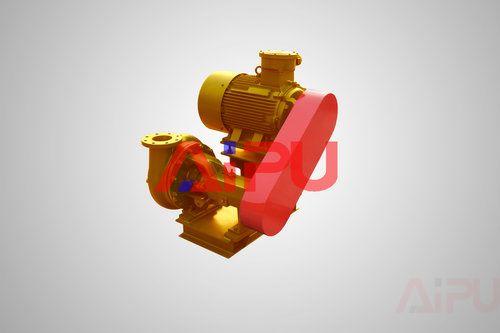

Structure of shear pump

The shear pump is composed by impeller, volute, support, packing case, transmission shaft, pulley, combination belt and electrical machine. The impeller of the shear pump is different with the water pump, the structure is more complex. It is the core part of the shear pump, with high efficiency.

The impeller is made up by five parts: axial compressor turbine, stock solution tank, pump impeller, pressure cabin and shear plate. The axial compressor turbine, pump impeller and stock solution tank were cased critically as an ensemble by stainless steel, the structure is very compact.

Some notice in use process

1. After using shear pump, we should use clear water flush pipeline and shear pump, to avoid leftover block runner and nozzle of impeller.

2. Bearing bore is filled in grease about 10~20 ml every other week, combination seal cavity is filled in grease about 10~20 ml every day.

3. In winter, if the pump is not used for a long time, drilling fluids in pump shell should be discharged, to avoid drilling fluids freeze.

As a professional manufacturer of solids control system in China, Aipu is a vital part of the world hydrocarbon exploration and production industry, as well as one of top three solids control equipment suppliers in China, which can offer a complete line of solids control equipment. Welcome to Aipu solids control.