Solids control system is the unit to process or remove drilled cuttings and unnecessary solid in drilling fluids. Drilling fluid process is the procedure get rid of drilling waste. What is drilling waste then? It including drilling cuttings, waste drilling fluid, and the associated drilling fluid

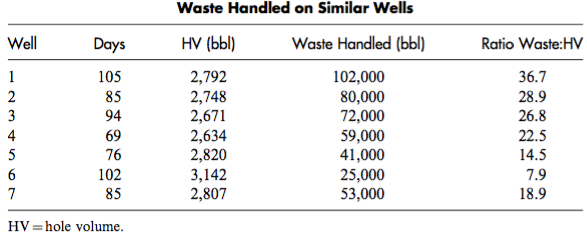

Total fluid management is comprehensive process. One of the largest sources of drilling waste for onshore operations is location water. This happens to be the source that can be reduced most. Most wastewater originates from drilling-fluid usage, storm water, rig wash water, or cooling water. The volume of location water requiring handling and disposal could be as much as 30 times the hole volume!

The approaches taken to reduce wastewater generation were based on reuse of as much water as possible. They included the following techniques:

1. Single-pass systems, such as cooling water, brake water, and seal water, were eliminated. These should be contained by enclosed systems.

2. Storm water was reused. Storm water can be reused for fluid makeup water, although the drilling personnel may not like it much.

3.The dirtiest water (such as drilling-fluid waste) was used for slide wash water. Desanders and desilters generate copious amounts of drilling-fluid waste (usually calculated at two or three parts liquid to one part solid), yet still require washing to the disposal pit. Shaker slides and centrifuge slides almost always require wash water.

4. Liquid waste was not generated needlessly.

5. Wastes that were to be handled in different ways were separated.

In future posts, we'll introduce more details on drilling fluid waste management. Please come to me anytime with any question.