Cuttings drying is sometimes referred to as secondary drying of cuttings. Drilled cuttings with associated fluid from the rig solids-control equipment have been passed over a second drying shaker for a number of years. The recovery of oil-based drilling fluid coupled with a 10 25% reduction in disposal volume is usually easily justified and has become standard procedure in areas where so-called pitless drilling or closed loop systems are the norm.

Generally, the secondary drying shaker is a four-panel screening device running at 7.0 7.3 g’s at the screen surface. Drilled cuttings from a drying shaker typically test between 8 and 12% base oil (NAF) by wet weight. This retention-on- cuttings (ROC) figure is significantly higher than the current minimum allowed for offshore discharge in many countries and increasingly territory around the world. Accordingly, there has been increased interest in lowering the ROC figure by the use of different types of drying equipment.

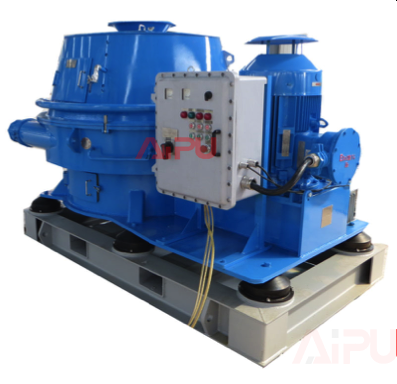

The quest for improved technology to reduce the ROC figures is ongoing with a number of competing machines and technologies. At this time the market is composed of the following commercial products:

Vertical and horizontal cuttings dryer

Horizontal and vertical basket centrifuges

.

Basket centrifuges that move cuttings by vibration

.

Basket centrifuges that move cuttings with a scroll

.

Basket centrifuges that move cuttings with a so-called pusher rod

.

Basket centrifuges that move cuttings with vibration and a pusher rod .

Perforated rotating vacuum cylinders

And so on

Of these competing technologies, cutting dyers or the centrifuges (vertical and horizontal) using centrifugal force and a flighted scroll to effect separation make up approximately 80% of the units in use today Typical rotation speeds from 300 to 870 rpm provide a g force between 48 and 375 g’s. Retention time of the drilled solids within the screen basket, screen geometry, and basket rpm vary widely among units. Generally speaking, more rpm means more g force, drier drilled cuttings and more capacity.

Please feel free to contact Aipu solids control for more detail. We are very pleased to answer your doubt and propose the solution for you