Shale shaker deck angle adjustment in mud system

Shale shaker deck angle can be said the screen panel degree. All shakers in today's market will be configured with angle adjustment device. This design aim to provide optimal performance under certain drilling condition or mud property.

Shale shaker deck angle range

Many shaker manufacturers will make

shale shaker differ much. But the angles are usually from -1~+5°. In common daily operation, we suggest -1 ~ +3° as deck angle range. Downward angle can help us remove solids faster, especially, when the drilling fluid is with less water content but larger solid. Such angle will also give us higher flow rate during operation.

Mostly operator in oilfield will raise the deck angle uphill to get the drier solids separated out of fluid. Furthermore the upward angle will remit mud loss with retain fluid close to feeder end. But one point, kindly suggest the most uphill angle is 3°。 As too incline angle will definitely increase abrasion on screen panel. Finally, the screens will be much easier to fail

Deck angle adjustment device

There are mechanical adjustment, hydraulic adjustment, electrical adjustment. All of them can be adjusted during drilling without shut down. The mechanical one is popular since convenient and easy to operate. For mechanical one, we adjust the angle by handle wheel, or the handle lever. With the jack screw, the deck angle can be easily adjusted very soon by one person

Such mechanical jack screw requests little maintenance by greasing the screw. Always operate it according to user manual or instruction mark on shaker provided by manufacturer.

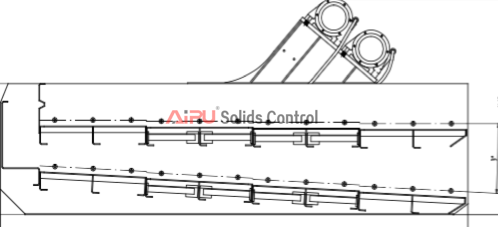

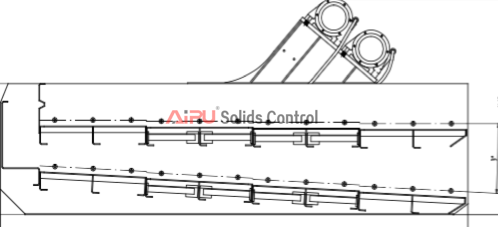

Deck angle of double decked shaker

Cater for different users demand we'll design the shale shaker with double or triple deck on one set shaker. The multiple deck will provide better separation and solids removal effect. Usually, we call first deck as scalping or primary to separate coarser particle, the second as secondary or drying deck to get the solids more drier and finer.

When we operate double decked shaker, the two shale shaker deck angle will be adjusted based on working condition. Such as drilling project, mud property, cuttings or solid detail. If we use shaker in TBM project, then the deck angle can be designed between -3~+3.5° for both deck. And we suggest 3° difference between 2 deck

shaker screen. For example, if the upper deck is 0°, the down deck should be -3°

This shale shaker deck angle post is a suggestion but not the necessary rules. Different project with various drilling mud will request different operation way. Please contact us for your best solution. No matter the Oil and gas drilling, HDD, TBM, and so on.