Why shale shakers performed badly than expectation

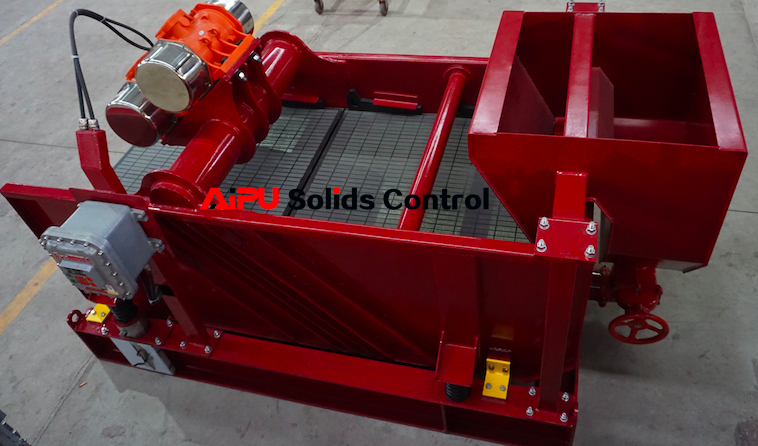

Shale shakers are economical equipment used in drilling mud process or the mine separation. It plays important role anywhere. If the filtered material is not as good as we thought we may think something wrong with shakers. What failures we may face when run shaker? How to solve such problems? There are many causes to lead bad shaker performance, such as block, overload material, improper screen tensioning, etc.

Shaker screen blocked by material

It's not uncommon shaker performed badly if there is block on

shaker screen mesh. As the blocking will decrease shaker screen effective area or non-blanked area. Thus the efficiency will be lower. When we face such problem, we should decrease the screen panel load and clean screen cloth timely.

When we solve the problem of block the shaker will perform well as usual. Processing material is at different level of viscosity. If the material is too sticky, there will be a ball and hard to pass though screen. Then, we can adjust shaker deck angle to improve filtration performance

Uneven feeding to shale shakers

If we feed drilling mud to shale shaker at unstable level, the shaker will perform worse than constantly stable feeding. Too little feeding will decrease efficiency much. However, too much feeding will pile up materials, especially, when material contain less water.

Overload of material on shaker deck will lead shaker fail soon. So, keep the material fed evenly to shaker. Furthermore, when there is too much material on shale shaker, the material will be too thick. Top layer material will not be filtered completely.

Improper screen installation

Shaker screen is important part on

shale shaker. It is the media for filtration or separation. Shaker screens tensioned not steadily with a little loose will affect filtration efficiency and whole shaker performance. Some shaker screens are tensioned by hook and draw bolts, while screen panels will be pressed by wedge blocks

No matter which installation, we should install them tightly and steadily. Thus the screen will be tensioned completely for better shaker performance.

Above information are general and simple summarize on shaker bad performance. Please come to us for more detail or any dbout. Aipu solids control is a professional manufacturer on shale shakers. Trust you'll get satisfied solutions soon