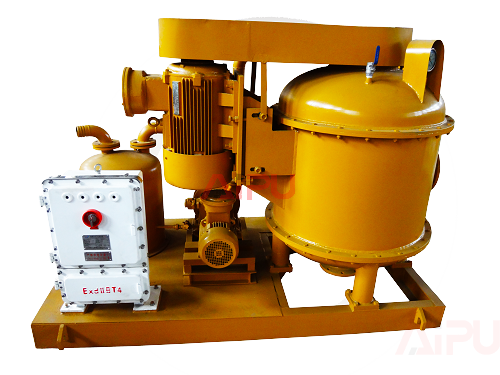

Some advices for vacuum degasser maintenance

Vacuum degasser maintenance

1. The top cover of the vacuum tank should be cleaned once a week to avoid sundried blocking the gas passage.

2. After use, cut off the power supply, remove the bottom of the blue block board, check if the parts are damaged, and remove the foreign body inside the tank, with high-pressure water pipe washing tank wall and the rotor.

3. After each drill shall be carried out in the above cleaning work, to ensure equipment can be used normally next time.

4. When vacuum degasser running, we should check the vacuum table at any time, adjust the vacuum valve to make the degree of vacuum in 0.03--0.05, to ensure the normal operation of the equipment.

5. After each use, should discharge water in water gas separator and pump.

6. Filling 250-300mL grease to main shaft bearing every other month.

7. After the removal of the vacuum pump, when installing please pay attention to the concentricity of the shaft coupling.

1. The top cover of the vacuum tank should be cleaned once a week to avoid sundried blocking the gas passage.

2. After use, cut off the power supply, remove the bottom of the blue block board, check if the parts are damaged, and remove the foreign body inside the tank, with high-pressure water pipe washing tank wall and the rotor.

3. After each drill shall be carried out in the above cleaning work, to ensure equipment can be used normally next time.

4. When vacuum degasser running, we should check the vacuum table at any time, adjust the vacuum valve to make the degree of vacuum in 0.03--0.05, to ensure the normal operation of the equipment.

5. After each use, should discharge water in water gas separator and pump.

6. Filling 250-300mL grease to main shaft bearing every other month.

7. After the removal of the vacuum pump, when installing please pay attention to the concentricity of the shaft coupling.