Shale shaker vibration theory

The vibration theory behind shale shakers is a fundamental aspect of their design and performance. Understanding how vibration influences the separation of solids and liquids is key to optimizing shaker efficiency in various drilling operations. Vibration theory can be explained by the interaction between mechanical forces, screen mesh, and the drilled fluid (mud) containing the cuttings.

Principle of Vibration in Shale Shakers

The vibration of a shale shaker is typically induced by one or two vibrating motors that drive the shaker’s screen to move in a specific pattern. There are two main types of motion in shale shakers: linear motion and elliptical motion. Both types of motion rely on the basic principle of vibration, which involves creating oscillating forces that cause the shaker screens to vibrate, forcing the solid particles (cuttings) to be separated from the fluid.

Types of Vibration Motion

1. Linear Motion: In linear motion shale shakers, the motion is straight and forward, creating a vibration that moves the fluid and solids directly across the screen. This type of motion is generally preferred in high-volume drilling operations where rapid and efficient solids separation is required.

2. Elliptical Motion: Elliptical motion creates a combination of linear and circular motion, which allows for better stratification of solids. This motion is often used for drilling fluids that contain a wider range of particle sizes, helping to remove both fine and coarse solids more effectively.

Vibration Frequency and G-Force

Vibration frequency refers to how many cycles per second the shaker screen undergoes, while G-force is the level of acceleration (gravity force) exerted on the screen. Both of these factors are adjustable on modern shale shakers and are vital in determining the efficiency of the solid-liquid separation process. A higher frequency and G-force usually lead to better separation, especially in the case of fine or difficult-to-remove solids.

Factors Affecting Vibration Performance

Several factors can influence the vibration performance of a shale shaker, including:

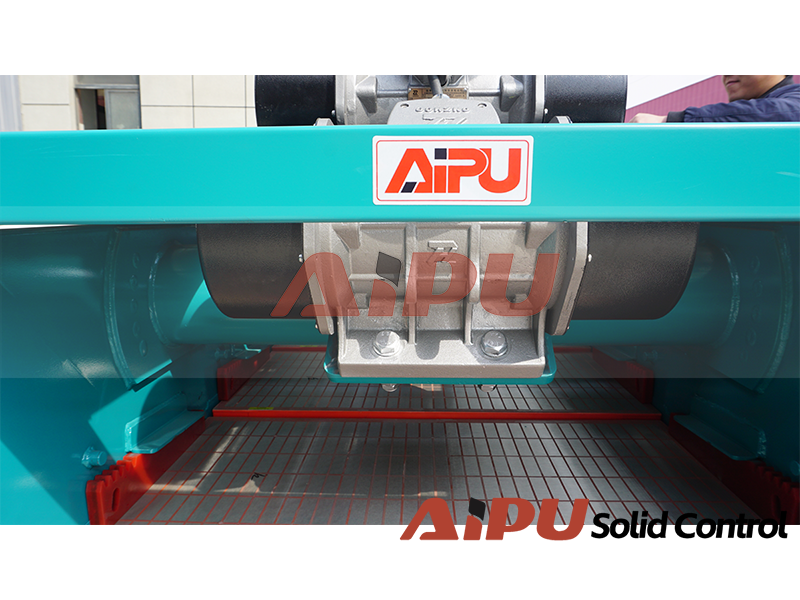

- Vibration Motor Size and Power: The strength and power of the motor directly impact the amplitude and frequency of the vibrations, and thus the shaker’s overall performance.

- Screen Tension: The tension applied to the screen affects its response to vibrations. Too much or too little tension can lead to poor separation or excessive wear on the screen.

- Screen Mesh Size: The mesh size determines the size of solids that the shaker can effectively separate. Finer mesh requires more vibration to separate small particles from the fluid.

- Flow Rate: The flow rate of the drilling fluid through the shaker screens influences the vibration performance. Higher flow rates generally require higher vibration intensities to achieve proper separation.

Importance of Vibration in Shale Shaker DesignThe vibration characteristics of a shale shaker are vital for ensuring optimal separation of drilling cuttings and fluid. By fine-tuning vibration parameters such as frequency, G-force, and motion type, shale shakers can be optimized to handle specific drilling conditions, improving operational efficiency and extending equipment lifespan. An efficient shaker system minimizes downtime and reduces the costs associated with drilling fluid loss, contributing to a more cost-effective drilling operation.

Why Choose Aipu Solid Control

Aipu Solid Control is a leading manufacturer of shale shakers, offering advanced vibration technologies for enhanced performance. Aipu’s shale shakers are designed with cutting-edge vibration technology that improves separation efficiency, reduces maintenance, and increases the overall longevity of the equipment. Their custom solutions are ideal for both high and low-volume drilling operations and are tailored to meet specific operational needs.