Best Materials for Manufacturing Mud Cleaner

In the demanding world of drilling operations, efficiency and cost-control are paramount. The management of drilling fluid, or mud, is a critical component that directly impacts both. A high-performance mud cleaner represents a significant technological advancement in solid control systems, offering a robust solution for maintaining optimal fluid properties. This equipment combines the principles of a desander and a desilter with a fine-screen shaker, creating a powerful multi-stage purification unit. By efficiently removing a wide range of drilled solids, from coarse to fine particles, it ensures the drilling fluid retains its essential chemical and physical characteristics. The result is a cleaner mud that enhances the rate of penetration, protects expensive downstream equipment from abrasive wear, and substantially reduces the volume of waste generated on site. Investing in a superior solids control solution is not merely an equipment purchase; it is a strategic decision for improving overall operational integrity and financial performance.

Enhanced Drilling Efficiency and Rate of Penetration

The presence of excessive drilled solids in the mud column increases its density and viscosity, creating a thicker fluid that is harder to pump. This places a greater load on the mud pumps and can significantly slow down the drill bit's progress. A high-performance mud cleaner aggressively removes these unwanted solids, allowing the mud to remain thin and pumpable. This reduction in fluid resistance enables the drill bit to cut through formations faster, leading to a markedly improved Rate of Penetration (ROP). Faster drilling translates directly into shorter project timelines and substantial cost savings on rig time, which is often the single largest expense in any drilling operation.

Superior Protection for Critical Drilling Equipment

Drilling mud laden with abrasive sand and silt particles acts like liquid sandpaper, causing severe erosion and wear on vital components. Equipment such as mud pumps, drill pipe, and even the blowout preventer (BOP) are susceptible to this damage. The cost of repairing or replacing this equipment is exorbitant, not to mention the costly non-productive time (NPT) associated with equipment failure. A mud cleaner serves as a primary defense line, meticulously removing these abrasive particles from the fluid cycle. By ensuring that only clean, conditioned mud is circulated, the equipment dramatically extends the service life of the entire drilling assembly, minimizing downtime and reducing maintenance costs.

Significant Reduction in Drilling Fluid Costs

Drilling fluid is a complex, engineered mixture, and its chemical components represent a major recurring cost. When solids are not efficiently removed, the fluid's properties degrade, requiring constant dilution with water and the addition of fresh chemicals to maintain its specifications. This leads to a vicious cycle of increasing fluid volumes and chemical consumption. A high-performance mud cleaner breaks this cycle by maintaining the mud's properties for longer periods. With fewer solids, there is less need for dilution, which means lower consumption of water, bentonite, polymers, and other additives. This efficient fluid management leads to direct and significant savings in mud-related expenses.

Improved Wellbore Stability and Hole Cleaning

Effective hole cleaning is essential for a safe and successful drilling operation. If cuttings are not efficiently transported to the surface, they can settle and form a thick bed in the annulus, leading to packing-off, stuck pipe, and other dangerous situations. Furthermore, fine particles can plaster the wellbore wall, potentially causing instability. A mud cleaner contributes to superior hole cleaning by ensuring the drilling fluid has the correct rheological properties to carry cuttings effectively. A cleaner mud also forms a thinner, more resilient filter cake on the wellbore wall, which enhances stability and reduces the risk of differential sticking.

Environmental and Waste Management Advantages

Modern drilling operations are subject to stringent environmental regulations. The volume of drilling waste generated is a key concern, both from a disposal cost and an environmental impact perspective. By removing a higher percentage of solids at the surface, a mud cleaner significantly reduces the total volume of waste drilling fluid and cuttings that require processing, hauling, and disposal. This not only lowers waste management costs but also minimizes the operation's environmental footprint. In many cases, the separated solids are drier and more stable, making them easier to handle and dispose of in an environmentally responsible manner.

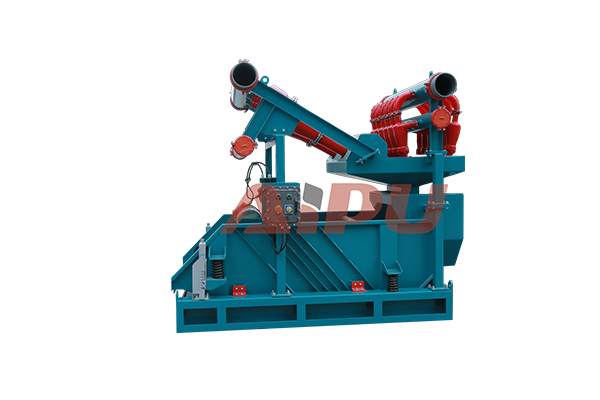

Selecting the right solid control equipment is a crucial decision that influences the entire drilling campaign. The operational and economic advantages of deploying a high-performance mud cleaner are clear and substantial. For companies looking to source reliable and efficient equipment, Aipu Solid Control stands out as a leading manufacturer in the industry. With a strong reputation for quality and durability, Aipu's mud cleaners are engineered to deliver peak performance in the most challenging conditions. If you are planning to procure a mud cleaner, prioritizing Aipu for your equipment needs is a strategic choice for achieving superior operational results and maximizing your return on investment.