How to Improve Mud Cleaner Screen Performance

In the demanding world of drilling operations, managing drilling fluid properties is paramount to efficiency, safety, and cost-effectiveness. Among the most challenging scenarios is dealing with high-viscosity fluids. These thick, often heavy-weighted muds are essential for wellbore stability in high-pressure formations, but they present significant hurdles for the solids control system. Their inherent thickness makes it difficult for standard equipment to separate drilled solids efficiently. This inefficiency leads to a rapid accumulation of fine particles and colloids, which further exacerbates the fluid's viscosity in a detrimental cycle. The consequences are severe: reduced rates of penetration, increased risk of stuck pipe, excessive pump pressure, and accelerated wear on drilling equipment. Effectively breaking this cycle requires a specialized and robust solution within the solids control hierarchy, a task for which the mud cleaner is uniquely suited. This equipment combines the principles of a desander and a desilter with a fine-screen shaker to tackle the specific challenges posed by heavy, viscous fluids.

The Challenge of High-Viscosity Drilling Fluids

High-viscosity fluids are not inherently problematic; they are often a necessary component of the drilling program. Their primary function is to carry cuttings out of the wellbore and maintain pressure control. However, their thick consistency acts as a transport medium for drilled solids. As the fluid circulates, it grinds these solids into progressively smaller particles. In a low-viscosity fluid, these fines might be removed by centrifuges or other equipment, but in a thick fluid, they remain suspended. The accumulation of these low-gravity solids, particularly those in the 5 to 75-micron range, is the primary driver of uncontrolled viscosity. This buildup increases the fluid's gel strength, making it harder to pump and reducing hydraulic efficiency. Furthermore, it can blind the screens of primary shale shakers, causing fluid loss and forcing a bypass of critical solids control steps.

How a Mud Cleaner Breaks the Viscosity Cycle

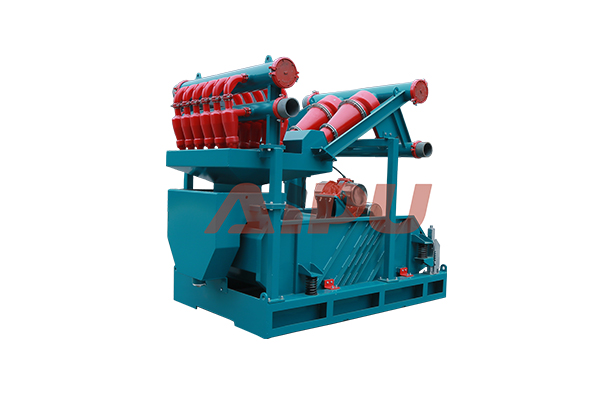

A mud cleaner is engineered to address this specific problem. It functions as a hybrid device, typically positioned after the shale shakers and degasser but before the centrifuges in the fluid processing line. Its operation is a two-stage process. First, the fluid is fed into a bank of hydrocyclones, similar to those used in desanders and desilters. These cones use centrifugal force to separate particles based on size and density. The heavier, coarser solids are forced to the walls of the cone and ejected from the bottom apex, while the cleaned fluid exits from the top. The critical difference with a mud cleaner is what happens next. The underflow from the hydrocyclones—a slurry of liquid and the separated solids—is discharged directly onto a very fine mesh screen (often as fine as 200 mesh) on a vibrating shaker bed.

This second stage is what makes the mud cleaner indispensable for high-viscosity fluids. The vibrating screen allows the valuable, high-density liquid phase of the mud to pass through and return to the active system. Simultaneously, it captures and removes the drilled solids that the hydrocyclones separated out. This process is vital because high-viscosity, barite-weighted muds are expensive. A standard desander or desilter would discard the entire underflow—both solids and liquid—leading to an unacceptable loss of drilling fluid and weighting material. The mud cleaner mitigates this economic loss by recovering the liquid and barite while efficiently discharging the harmful, low-gravity drilled solids.

Key Operational Advantages in Viscous Fluid Applications

The deployment of a mud cleaner offers several distinct advantages when processing high-viscosity fluids. The most significant is the direct control over mud properties. By systematically removing fine solids, the equipment prevents the exponential rise in plastic viscosity and yield point, maintaining the fluid in its optimal rheological range. This leads to improved hydraulic horsepower at the bit, resulting in faster drilling rates. It also reduces the torque and drag on the drill string, minimizing the potential for stuck pipe incidents. From a financial perspective, the mud cleaner extends the life of the drilling fluid, reducing the need for costly dilution or wholesale mud replacement. It also protects downstream equipment, such as centrifugal pumps and mud centrifuges, from being overloaded with abrasive solids, thereby lowering maintenance costs and downtime.

Best Practices for Optimal Mud Cleaner Performance

To maximize the effectiveness of a mud cleaner, certain operational practices must be followed. Proper equipment sizing is crucial; the unit must be capable of handling the full flow rate of the drilling fluid. The selection of hydrocyclone size (e.g., 4-inch or 5-inch cones) should be based on the particle size distribution that needs to be removed. The screen mesh on the bottom shaker is equally important. It must be fine enough to retain the valuable barite but allow the fluid to pass through freely. Regular monitoring of the fluid's mud properties—including mud weight, viscosity, and solids content—is essential to fine-tune the operation. Operators should also pay close attention to the spray pattern from the hydrocyclones and the dryness of the solids discharged from the screen, as these are key indicators of optimal performance.

Effectively handling high-viscosity fluids is a complex but manageable task with the right equipment. The targeted removal of fine solids is the key to maintaining fluid performance and overall drilling efficiency. For operations consistently facing these challenges, investing in a robust solids control system that includes a high-quality mud cleaner is not just an option but a necessity for operational and economic success.

When considering the procurement of reliable solids control equipment, Aipu Solid Control stands out as a leading manufacturer. With a strong reputation for building durable and efficient machinery, Aipu offers a range of mud cleaners designed to perform in the most demanding drilling environments. If you are looking to enhance your fluid processing capabilities, prioritizing Aipu for your mud cleaner needs is a strategic decision for achieving superior operational results.