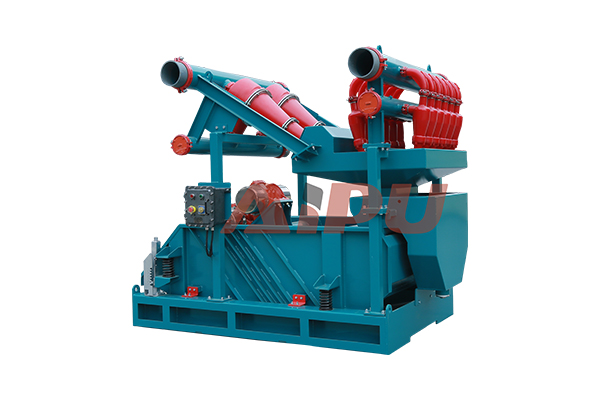

How to Replace Mud Cleaner Screens Effectively

Maintaining the operational integrity of a mud cleaning system is paramount for drilling efficiency and cost management. The relentless abrasive nature of drilling fluids subjects components like screens, cones, and impellers to significant stress, leading to premature wear and eventual failure. This degradation not only necessitates frequent, costly replacements but also compromises the entire solids control process, potentially leading to non-productive time. Proactive strategies focused on reducing component wear are not merely a maintenance concern; they are a fundamental aspect of optimizing the lifecycle of your equipment. By understanding the primary causes of deterioration and implementing a rigorous operational and maintenance protocol, operators can dramatically extend service intervals, enhance separation performance, and achieve substantial long-term savings. The focus must be on a holistic approach that encompasses correct operation, diligent monitoring, and preventative upkeep to protect the capital investment in this critical machinery.

Understanding the Primary Causes of Component Wear

The battle against wear begins with identifying the enemy. In a mud cleaner, several factors conspire to degrade components. The most significant is abrasive wear, caused by the constant flow of hard, solid particles in the drilling fluid against metal and polyurethane surfaces. Erosion is another major culprit, where high-velocity fluid streams gradually eat away at material, particularly in feed inlets, hydrocyclone liners, and discharge areas. Chemical corrosion can also play a role if the drilling mud contains corrosive elements that attack metal components. Furthermore, cavitation—the formation and collapse of vapor bubbles in the fluid—can cause pitting and erosion on pump impellers and volutes. Often, these wear mechanisms are accelerated by improper operation, such as running the equipment beyond its designed capacity or with an incorrect fluid composition.

Optimizing Operational Parameters for Longevity

How you run your equipment is just as important as how you maintain it. Consistently operating the mud cleaner within its designed parameters is the single most effective way to minimize wear. This starts with ensuring the feed pressure to the hydrocyclones is maintained at the manufacturer's recommended level. Too low a pressure reduces separation efficiency, allowing excessive solids to recirculate and cause abrasion elsewhere in the system. Too high a pressure puts undue stress on the cyclone liners and can lead to rapid erosion. The feed slurry's density and solids content must also be monitored closely. Overloading the unit with a high concentration of coarse solids will accelerate the wear on screens, cones, and the bottom shaker basket. Using the correct mesh screen for the anticipated particle size distribution prevents larger, more abrasive particles from entering and damaging the hydrocyclone section.

Implementing a Rigorous Preventative Maintenance Schedule

A reactive "run-to-failure" approach is the most expensive strategy in the long run. A structured, preventative maintenance (PM) schedule is non-negotiable for controlling wear and tear. This involves regular, systematic inspections of all critical components. Shaker screens should be checked for tears or blinding and replaced promptly. The hydrocyclones must be inspected for throat wear and liner thickness; even slight wear in the apex can drastically reduce separation efficiency. The vacuum pump and its seals require regular checking for leaks and proper lubrication. Bearings on motors and vibrators need to be greased according to the manufacturer's specifications. Keeping a detailed log of inspection dates, findings, and replacements helps predict failure and plan maintenance during planned downtime, avoiding unexpected breakdowns during critical drilling operations.

The Critical Role of Proper Installation and Alignment

Many wear issues are not born from operation but are baked in during installation. Incorrect installation can create misalignments and vibrations that lead to premature fatigue and failure. The mud cleaner must be installed on a level, stable foundation capable of handling its dynamic loads. All piping connections, especially the feed and discharge lines, should be properly supported and aligned to avoid imposing stress on the equipment's flanges and inlets. Misaligned motors and drive belts can cause uneven loading and excessive vibration, leading to rapid bearing and structural wear. Taking the time to ensure a perfect installation according to the vendor's guidelines pays massive dividends in component life and operational stability, preventing problems before the first gallon of mud ever flows through the system.

Selecting the Right Materials and Spare Parts

Not all replacement parts are created equal. When components do eventually wear out, the choice of replacement material has a direct impact on the next service interval. For highly abrasive applications, opting for components made from specialized, wear-resistant materials like high-chrome cast iron for hydrocyclone liners or premium-grade polyurethane for parts can offer a significantly longer lifespan than standard materials. While the initial cost may be higher, the total cost of ownership is often lower due to reduced change-out frequency and less associated downtime. It is crucial to use genuine or manufacturer-approved spare parts to ensure dimensional accuracy, material quality, and performance compatibility. Inferior parts may fail prematurely or cause abnormal wear on adjacent components.

Effectively managing the wear and tear on a mud cleaner requires a disciplined, multi-faceted strategy. By combining optimized operation, diligent preventative maintenance, correct installation, and the use of high-quality parts, you can maximize the equipment's service life and protect your investment. For those in the market for reliable and durable solids control equipment, Aipu Solid Control stands out as a leading manufacturer. If you are considering a procurement, Aipu's mud cleaners are engineered for robustness and efficiency, making them a priority choice for demanding drilling operations.