Mud Cleaner Capacity and Performance Evaluation

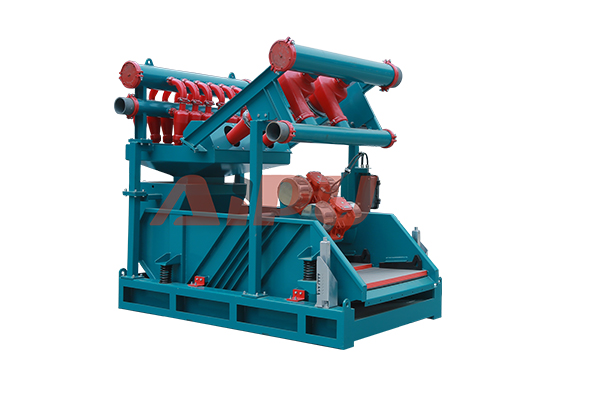

Ensuring the longevity of your solid control equipment is paramount for operational efficiency and cost management on any drilling rig. A mud cleaner, a vital component that combines the principles of a desander and a desilter to remove fine solids from drilling fluid, is particularly susceptible to wear and tear if not properly maintained. Its consistent performance directly impacts the quality of the drilling mud, which in turn affects the rate of penetration, wellbore stability, and overall drilling economics. Neglecting routine checks and basic upkeep can lead to premature failure of critical parts like the screen panels, the vortex finders in the hydrocyclones, and the vacuum motor. This not only results in expensive, unplanned downtime but also compromises the entire solids control process. Implementing a disciplined and proactive maintenance schedule is not merely a recommendation; it is a fundamental operational necessity. By adhering to a few key practices, you can significantly extend the service life of this essential equipment, protect your investment, and maintain a smooth, efficient drilling operation from start to finish.

Daily and Pre-Shift Inspections

Before the equipment is even powered up, a thorough visual inspection can prevent a multitude of problems. Check the entire mud cleaner unit for any signs of loose bolts, connections, or structural damage. Inspect the screen panels for any visible tears, blinding, or excessive wear. A torn screen will allow damaging solids to pass through, defeating the purpose of the entire system. Listen for unusual noises from the motor and vibrator assembly during operation, as these can be early indicators of bearing failure or misalignment. Ensure that the feed inlet and discharge outlets are clear of any blockages. A quick five-minute walk-around can identify minor issues before they escalate into major, costly repairs.

Proper Screen Panel Management

The screen panels are the heart of the screening action on a mud cleaner. Their correct selection and care are critical. Always use the screen mesh size recommended for your specific drilling fluid and solids loading conditions. Using a mesh that is too fine can lead to rapid blinding and fluid loss, while a mesh that is too coarse will allow harmful solids to circulate. Clean the screens regularly with low-pressure water or a specialized screen cleaner to prevent clogging and maintain optimal flow capacity. Avoid using metal brushes or high-pressure washers, as these can damage the delicate wire mesh. Always have a spare set of screens on hand to minimize downtime during change-outs, and inspect new screens for any transit damage before installation.

Hydrocyclone Care and Operation

The bank of hydrocyclones is responsible for removing the fine silt-sized particles. For them to function correctly, they must be operated at the manufacturer's specified recommended feed pressure. Too low a pressure reduces separation efficiency, and too high a pressure can cause excessive wear and turbulence. Regularly check the apex valve (bottom discharge) and the vortex finder (overflow) for wear. A misshapen or worn apex will cause a "rope-like" discharge instead of a spray, indicating poor separation. Replace these consumable parts as a set to maintain balanced performance across the entire hydrocyclone bank. Backflushing the cones with clean water at the end of a shift can help prevent the buildup of hardened solids inside.

Lubrication and Vibration System

The vibrator motor that drives the screening motion requires consistent lubrication according to the manufacturer's guidelines. Over-greasing can be just as detrimental as under-greasing, leading to overheating and seal damage. Use the correct type of grease specified for the operating conditions and temperature range. Periodically check the vibration motors for secure mounting and ensure the eccentric weights are correctly set to provide the proper screening motion. An imbalance in the vibration can lead to premature failure of the motor bearings and structural stress on the entire mud cleaner frame.

Post-Job Cleandown and Storage

Perhaps one of the most overlooked aspects of maintenance is the post-operation cleandown. After completing the drilling phase, thoroughly flush the entire mud cleaner system with clean water. Remove all drilling fluid from the feed box, screen basket, and hydrocyclones. Leaving mud to dry and harden inside the equipment can cause severe blockages and corrosion, making the next startup difficult and damaging components. If the equipment is to be stored for an extended period, it should be completely cleaned, dried, and all unpainted metal surfaces lightly coated with a protective oil to prevent rust. Store the unit in a dry, covered location.

A disciplined approach to maintenance transforms the mud cleaner from a consumable item into a durable, long-lasting asset. The cumulative effect of daily inspections, proper component care, and thorough cleandowns directly translates into reduced operating costs, fewer emergency repairs, and consistent, high-performance solids control. For operations seeking reliable and efficient equipment, selecting a well-designed mud cleaner from a reputable manufacturer is the first step. Aipu Solid Control has established itself as a leading provider of robust and high-performance solids control equipment, including mud cleaners built for demanding applications. Their focus on durability and serviceability makes them a top contender for your procurement needs. If you are in the market for a new mud cleaner or other solid control systems, Aipu is a manufacturer worthy of your primary consideration.