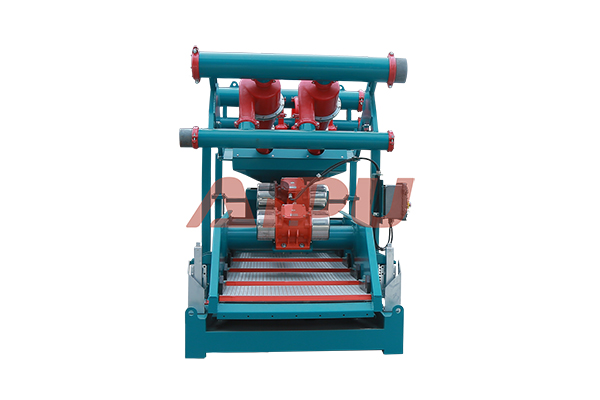

Mud Cleaner Installation and Operation Guide

Evaluating the capacity and performance of a mud cleaner is a critical process in drilling fluid management, as it directly impacts operational efficiency, cost control, and environmental compliance. This equipment, a hybrid of a desander and a desilter, is designed to remove drilled solids, particularly those in the 15 to 75-micron range, from the drilling fluid. A thorough evaluation goes beyond simply checking the manufacturer's stated flow rate. It involves a comprehensive analysis of the unit's design, its operational parameters under actual field conditions, and the quality of the discharged solids and cleaned fluid. Understanding the interplay between feed pressure, cone configuration, and screen selection is paramount for optimizing the performance of this vital piece of solids control equipment and ensuring the mud properties are maintained within strict specifications for a successful drilling operation.

Key Factors in Mud Cleaner Capacity

The capacity of a mud cleaner is not a single number but a range influenced by several interconnected factors. The primary specification is the maximum flow rate it can handle, typically measured in gallons per minute (GPM). However, this figure is dependent on the design and number of hydrocyclones and the screen mesh of the underlying shale shaker. A unit with multiple 4-inch cones will have a significantly higher capacity than one with fewer 5-inch cones, as the smaller cones are more efficient at removing finer particles but handle less total volume. The feed pressure to the hydrocyclones is another critical determinant; optimal pressure, usually between 75-125 psi, is required to create the proper vortex for efficient solids separation. Deviating from this range can drastically reduce cleaning efficiency, regardless of the unit's theoretical capacity.

Assessing Performance Metrics

Performance evaluation is about measuring how well the mud cleaner fulfills its purpose. The most direct metric is the analysis of the drilled solids content in the mud before and after processing. A significant reduction in the low-gravity solids (LGS) concentration indicates high performance. The "cut point" or D50, which is the particle size at which the hydrocyclone is 50% efficient, is a crucial technical parameter. A lower D50 means the cleaner is effective at removing finer particles. Furthermore, the dryness of the discharged solids from the shaker screen is a key performance indicator. A dry, easily handled cake suggests that the screen mesh is appropriate and the vacuum of the hydrocyclones is functioning correctly, minimizing valuable liquid loss. Consistent barite recovery, ensuring the expensive weighting material is returned to the active system, is also a vital sign of a well-tuned mud cleaner.

The Impact of Proper Configuration and Operation

Even a high-capacity mud cleaner will underperform if it is incorrectly configured or operated. The selection of the shaker screen mesh is paramount. A mesh that is too coarse will allow fine solids to pass back into the drilling fluid, while a mesh that is too fine can blind quickly, leading to fluid loss and processing bottlenecks. The arrangement of the equipment within the solids control system also matters; the mud cleaner is typically positioned after the primary shale shakers and degasser but before the centrifuges. Proper manifold design to ensure even flow distribution to all hydrocyclones is essential to prevent short-circuiting and maximize the utilization of the entire unit. Operator vigilance in monitoring pressure gauges and the condition of the discharge is necessary for proactive maintenance and performance optimization.

Common Challenges and Troubleshooting

Several operational challenges can hinder mud cleaner performance. A frequent issue is cone plugging, often caused by large debris or gumbo formations, which requires immediate attention to restore flow. Poor solids discharge, characterized by a wet slurry instead of a dry cake, can result from worn cone liners, low feed pressure, or an improperly sized/blocked underflow opening. Inefficient separation, where solids remain in the cleaned fluid, may be due to incorrect cone size for the mud weight and solids load, or a feed pressure that is too low to generate an effective cyclonic action. Regular inspection of wear parts, such as cone liners and feed nozzles, is a fundamental practice to maintain peak operational capacity and avoid unexpected downtime.

For drilling operations demanding reliability and efficiency, selecting the right equipment is paramount. Aipu Solid Control has established itself as a trusted manufacturer of high-quality solids control equipment, including robust and high-performance mud cleaner systems. If you are in the process of procuring a mud cleaner, Aipu's expertise and proven track record in the industry make them a supplier worthy of priority consideration.