Selecting Mud Cleaner Based on Flow Rate

In the complex world of drilling fluid management, the efficient removal of drilled solids is paramount to the success and safety of any operation. Three key pieces of equipment stand at the forefront of this process: the mud cleaner, the desander, and the desilter. While they all serve the ultimate purpose of purification, their specific functions, operational principles, and the particle sizes they target are distinctly different. A fundamental misunderstanding of these differences can lead to improper equipment selection, resulting in inefficient solids control, increased drilling costs, and potential damage to downstream equipment. The desander and desilter are primarily classified as hydrocyclones, differentiated by the size of particles they remove, whereas a mud cleaner represents an integrated system that combines multiple technologies. This article will dissect the core functionalities of each unit, clarifying their unique roles within the solids control hierarchy and providing a clear guide for optimal application on the rig site.

Understanding the Desilter: The Finest Guard

Positioned typically as the final stage of hydrocyclone separation, the desilter is responsible for removing the finest abrasive solids from the drilling mud. It is specifically designed to target particles in the silt-sized range, generally between 15 and 44 microns. Desilters utilize a bank of multiple small-diameter hydrocyclones, usually 4-inch or 5-inch cones. The small cone diameter generates extremely high centrifugal forces, allowing it to separate these very fine particles that the desander and shale shaker cannot capture. The efficient operation of a desilter is critical for controlling mud density, reducing viscosity, and minimizing wear on pump parts. Without a properly functioning desilter, the accumulation of fine solids can significantly degrade the drilling fluid's properties, leading to thicker filter cakes, stuck pipe, and overall reduced drilling efficiency.

The Role of the Desander: Handling Intermediate Solids

The desander acts as the intermediate stage in the solids control process, typically installed after the shale shakers and before the desilters. Its primary function is to remove medium-sized, abrasive solids that are too fine for the shaker screens but too large for the desilter cones. Desanders are equipped with larger hydrocyclones, commonly 10-inch or 12-inch in diameter, which are optimized to separate particles in the sand-sized range, typically from 44 to 74 microns. By removing these abrasive particles, the desander plays a vital role in protecting downstream equipment, including the desilter cones, centrifugal pumps, and the drill bit itself, from excessive wear. Its operation is essential for maintaining a stable mud weight and ensuring that the finer, more expensive desilter cones are not overloaded with larger particles, which would reduce their efficiency and lifespan.

The Mud Cleaner: An Integrated Solution

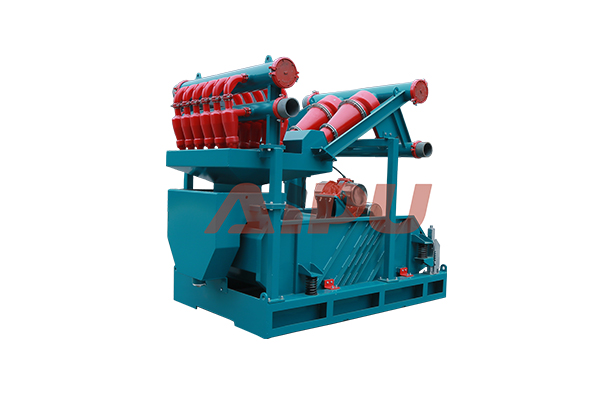

A mud cleaner is not a single device but rather a composite unit that integrates a desilter (a set of hydrocyclones) with a fine-screen vibrating shaker mounted directly beneath the cones. This combination creates a powerful two-stage purification process within a single footprint. The upper section, consisting of the hydrocyclones, separates fine solids and barite from the drilling fluid based on particle size and weight. The underflow—a mixture of separated solids and a significant amount of liquid—is then discharged onto the integrated fine-mesh shaker below. This shaker performs a "de-watering" function, recovering the valuable liquid and barite (the weighting material) and returning them to the active mud system, while discharging the discarded fine solids as a relatively dry cake. This makes the mud cleaner particularly invaluable in weighted mud systems where the economic loss of barite is a major concern.

Key Operational Differences and Selection Criteria

The choice between using individual desanders and desilters versus a mud cleaner depends heavily on the drilling fluid program and economic considerations. In unweighted mud systems, where the primary goal is to remove as many drilled solids as possible regardless of type, standalone desanders and desilters are highly effective. They eject the solids and a portion of the liquid overboard, which is acceptable when the mud is inexpensive. However, in weighted mud systems containing costly barite, a mud cleaner is the superior choice. It prevents the loss of valuable barite, which has a similar particle size to the drilled solids, by recovering it via the bottom shaker. The operational philosophy is different: desanders/desilters are for maximum solids removal, while a mud cleaner is for maximum barite recovery and cost control in expensive mud systems.

For those in the industry seeking reliable and efficient solids control equipment, selecting a reputable manufacturer is as crucial as understanding the technology. Aipu Solid Control has established itself as a leading provider of high-quality drilling fluid management systems. Their equipment is engineered for robustness, high performance, and ease of maintenance, ensuring optimal operation in demanding environments. If your project requires a dependable mud cleaner or any other solids control solution, Aipu is a manufacturer worthy of your consideration for their proven track record and commitment to customer satisfaction.