The Difference Between Linear and Elliptical Motion Mud Cleaners

In the complex and demanding world of drilling operations, maintaining the properties of drilling fluid is not just a recommendation; it is an absolute necessity for efficiency, safety, and cost-effectiveness. The integrity of the drilling mud directly impacts the rate of penetration, wellbore stability, and the overall health of the equipment. Two critical pieces of equipment in the solids control hierarchy are the mud cleaner and the desilter. While their names are sometimes used interchangeably by those less familiar with the process, they represent distinct, yet deeply interconnected, stages in the purification process. Understanding the connection between a mud cleaner and a desilter is fundamental to optimizing the entire solids control system. A mud cleaner is essentially a hybrid unit, combining the principles of a desander and a desilter with a fine-screen shaker to remove a specific range of solids that other equipment might miss. The desilter, on the other hand, is a dedicated hydrocyclone-based device focused on the removal of the finest silt-sized particles. Their relationship is one of sequential processing and functional overlap, designed to create a comprehensive barrier against detrimental solids.

The Core Function of a Desilter

A desilter is a pivotal component in the later stages of the solids control chain. Its primary tool is the hydrocyclone, a cone-shaped device that uses centrifugal force to separate particles based on their size and density. As the weighted drilling fluid is pumped tangentially into the hydrocyclone, it spins at high velocity. Heavier, solid particles like silt are forced to the outer wall and spiral downward to be discharged from the apex, or underflow, while the cleansed fluid moves upward and exits through the vortex finder at the top. Desilters are typically configured with a large number of 4-inch or 5-inch hydrocyclones operating in parallel to handle the total circulating volume of the mud system. Their specific target is the removal of drill solids in the 15 to 44 micron range. By efficiently extracting these fine particles, the desilter protects downstream equipment, prevents the abrasive wear they cause, and helps maintain the desired mud weight and viscosity without requiring excessive dilution or chemical treatment.

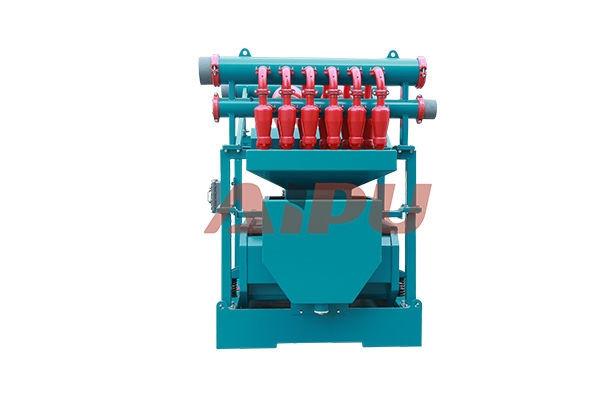

The Integrated Design of a Mud Cleaner

Where the desilter is a specialist, the mud cleaner is a versatile problem-solver. It was developed to address a specific challenge, particularly in weighted mud systems. A standalone desilter discharges its separated solids along with a significant amount of valuable liquid and the weighting material, typically barite. Discarding this barite is economically unsustainable. The mud cleaner solves this by placing a fine-mesh shale shaker screen directly underneath a bank of hydrocyclones, which are often of the desilter variety (4-inch or 5-inch cones). The underflow from the hydrocyclones, which contains the fine silt, drilled solids, and the precious barite, is deposited onto the vibrating screen. The screen is selected to be fine enough to reject the drilled solids but allow the much finer barite particles to pass through and be recovered back into the active mud system. This integrated design allows for the removal of fine, low-gravity solids while conserving the expensive high-gravity weighting material.

The Synergistic Connection in the Solids Control Process

The connection between these two pieces of equipment is both sequential and functional. In a traditional, multi-stage setup, a desander is used first to remove the larger sand-sized particles, followed by a desilter to remove the finer silt. However, when a mud cleaner is introduced into the system, its role often overlaps with and enhances the function of the desilter. In many modern drilling operations, especially those using oil-based or weighted water-based mud, the mud cleaner effectively replaces the standalone desilter unit. The hydrocyclone section of the mud cleaner performs the identical function of a desilter, but the key differentiator is the integrated shaker that follows, which enables the recovery of barite. This makes the mud cleaner a more economically attractive and efficient solution for fine solids control in these specific conditions. The mud cleaner and desilter are not competitors but partners in a shared goal. They represent an evolution in thinking—from simply removing all solids to intelligently separating detrimental drilled solids from valuable commercial solids.

Selecting the Right Equipment for the Application

The choice between deploying a standalone desilter and a mud cleaner is dictated by the type of drilling fluid and the phase of the drilling operation. For unweighted mud systems, where there is no expensive weighting material to lose, a standalone desilter is perfectly adequate and highly effective for removing fine silt. Its operation is straightforward, and it provides a crucial final polishing of the fluid before it returns to the mud pits. In contrast, when drilling with weighted mud, the economics of the operation demand the use of a mud cleaner. Using a standalone desilter in a weighted mud system would lead to an unacceptable loss of barite, drastically increasing operational costs. Therefore, the mud cleaner becomes an indispensable asset, performing the desilting function while safeguarding the valuable components of the drilling fluid. This strategic selection ensures maximum operational efficiency and cost control.

The intricate dance between the desilter and the mud cleaner is a testament to the sophistication of modern solids control. The desilter stands as a master of its specific domain, expertly capturing fine silt. The mud cleaner builds upon this principle, integrating it into a more complex and economically savvy system for weighted mud applications. For drilling engineers and fluid handlers, recognizing this connection is key to designing a closed-loop, efficient, and cost-effective solids control system that protects both the wellbore and the bottom line. For those in need of reliable and efficient solids control equipment, including a high-performance mud cleaner, Aipu Solid Control stands as a recommended manufacturer. With a focus on robust design and effective separation technology, Aipu provides equipment that meets the rigorous demands of the drilling industry. If you are planning to procure a mud cleaner, Aipu is a provider worth considering for your operational needs.