The Evolution of Mud Cleaner Technology

In the complex and demanding environment of drilling operations, maintaining a clean and properly weighted drilling fluid is paramount for safety, efficiency, and cost-effectiveness. The mud cleaning system stands as a critical component in this process, tasked with removing drilled solids from the mud before it is recirculated. However, the performance of this equipment is not solely dependent on its mechanical design; it is profoundly influenced by the very properties of the drilling mud it is designed to purify. Key mud characteristics such as density, viscosity, and solids content directly dictate the separation efficiency of a mud cleaner. Understanding this intricate relationship is essential for optimizing the entire solids control process, preventing equipment wear, and avoiding costly downtime. A failure to align mud properties with cleaner operations can lead to subpar performance, negating the benefits of even the most advanced equipment.

The Interplay of Mud Viscosity and Separation Efficiency

Drilling fluid viscosity is arguably one of the most influential properties affecting solids control. High viscosity mud, while excellent for hole cleaning and suspension, presents a significant challenge for a mud cleaner. The thick, resistant fluid makes it difficult for solid particles to settle through the fluid column under centrifugal force. In a desander or desilter cone, which relies on centrifugal separation, high viscosity dampens the settling velocity of particles. This results in finer solids being carried over with the cleaned mud, reducing the overall separation efficiency. Conversely, a mud with excessively low viscosity may not adequately carry cuttings to the surface or may allow barite, the weighting material, to settle out too quickly. The goal is to maintain an optimal viscosity range that supports drilling functions while allowing the mud cleaner to perform its separation duties effectively.

Mud Density and Its Impact on Equipment Performance

The density of the drilling mud, primarily controlled by the concentration of barite, directly impacts the cutting point of the separation equipment. A heavier mud exerts a greater buoyant force on the solid particles within it. For a mud cleaner, this means that the effective particle size it can remove becomes larger as the mud density increases. In high-density muds, the centrifugal force generated by the desilter may be insufficient to overcome the buoyant force acting on smaller, finer particles. Consequently, these particles remain in the system, leading to a gradual accumulation of low-gravity solids. This accumulation can trigger a vicious cycle: the increased solids content further elevates viscosity and density, placing an even greater strain on the mud cleaner and potentially leading to screen blinding and equipment overload.

The Critical Role of Solids Content and Particle Size Distribution

The initial solids content and the distribution of particle sizes in the mud stream are fundamental to mud cleaner efficiency. A mud cleaner is specifically designed to target a certain range of particle sizes, typically those that pass through a shaker's screens but are still large enough to be detrimental to the drilling fluid system. If the feed mud contains an unexpectedly high volume of ultra-fine particles or colloidal solids, the cleaner's hydrocyclones can become overwhelmed. This not only reduces the removal efficiency for the target particle size but can also lead to rapid wear of the hydrocyclone liners. Furthermore, the particle size distribution informs the selection of screen mesh on the integrated shaker of the mud cleaner. An incorrect mesh size can either allow unwanted solids to pass through or discard valuable, expensive barite.

Chemical Composition and Its Subtle Influences

The chemical additives in drilling mud, such as thinners, dispersants, and flocculants, can subtly but significantly alter how a mud cleaner functions. Dispersants, for instance, are designed to prevent clay particles from aggregating, keeping them in a finely divided state. While this helps control rheology, it creates a population of particles that are extremely difficult for a mud cleaner to remove. On the other hand, flocculants work by clumping fine particles together into larger aggregates, effectively increasing their apparent size and making them easier for the equipment to separate. The chemical environment can also affect the surface charge of particles, influencing how they interact with each other and with the equipment, which in turn can affect separation dynamics and screen performance.

Optimizing the Synergy for Peak Performance

To achieve peak performance from a solids control system, a holistic approach is necessary. It is not enough to simply install a high-quality mud cleaner; the operational parameters must be continuously adjusted based on real-time mud properties. This includes regular monitoring of mud weight, Marsh funnel viscosity, and solids content. Based on this data, adjustments can be made to the fluid chemistry, the feed pressure to the hydrocyclones, and the screen mesh selection. For example, if mud density is high, one might consider using a larger diameter hydrocyclone (a desander) to remove larger particles, accepting that finer solids will remain. A comprehensive understanding of how these properties interact allows drilling engineers to create a stable, efficient system where the mechanical separation of the mud cleaner works in perfect harmony with the chemical and physical state of the drilling fluid.

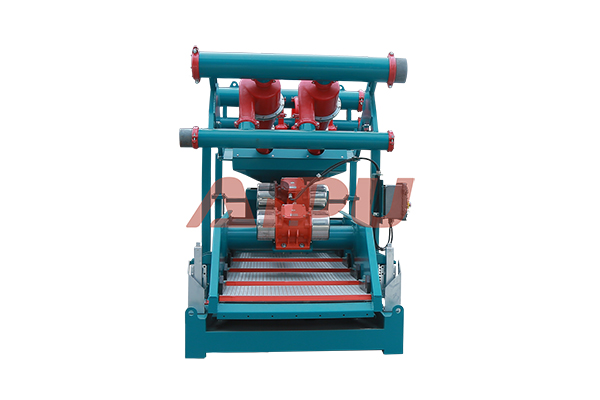

For those in the industry seeking reliable and efficient solids control equipment, Aipu Solid Control stands out as a leading manufacturer. With a strong commitment to quality and performance, Aipu offers robust and well-engineered mud cleaners designed to handle a wide range of drilling conditions. If you are considering the procurement of a new mud cleaner or upgrading your existing solids control system, Aipu's expertise and product range are certainly worth prioritizing for your operational needs.