The Relationship Between Mud Cleaner and Centrifuge

The world of drilling operations is a complex ballet of powerful machinery and precise processes, all working in concert to reach valuable subsurface resources. Among the critical components ensuring the efficiency and success of these operations is the often-overlooked mud cleaner. This vital piece of equipment sits at the intersection of two other key solids control devices—the desander and the desilter—and performs a unique function in managing drilling fluid. The lifecycle of a mud cleaner, from its initial deployment on a new well to its eventual decommissioning or refurbishment, is a story of continuous performance under extreme conditions. Understanding this lifecycle is crucial for drilling engineers and rig managers who aim to maximize equipment uptime, maintain optimal drilling fluid properties, and control operational costs. It is not merely a piece of static hardware but a dynamic system whose performance directly impacts the overall health and economics of a drilling project.

Design and Manufacturing: The Foundation of Performance

The lifecycle begins long before the mud cleaner ever reaches a drilling rig. It starts on the drawing board and factory floor. Engineers design these units to handle specific volumes, particle sizes, and abrasive materials. The core components typically include a high-speed vibrating screen, often a fine mesh, mounted atop one or more hydrocyclones. The construction materials are selected for durability and corrosion resistance, with high-strength steel for the structure and polyurethane or ceramic linings for the hydrocyclones to withstand the relentless abrasion from drilled solids. Manufacturing involves precision machining, robust welding, and rigorous quality control checks to ensure every unit can withstand the harsh realities of a drilling environment. Every weld, every motor, and every screen panel is built with the expectation of a long, productive service life.

Commissioning and Initial Deployment

Once delivered to the rig site, the mud cleaner enters its commissioning phase. This involves careful installation into the solids control system, typically after the shale shakers and before the centrifuges. Proper installation is critical; the unit must be level and securely fastened to handle the intense vibrations during operation. Electrical connections for the vibrator motor and the feed pump are finalized. The initial startup is a critical moment. Operators introduce drilling fluid to the system, checking for leaks, ensuring the hydrocyclones are generating the proper vacuum head, and confirming the screen is vibrating effectively to convey and discard solids. The initial performance data is recorded, establishing a baseline for future efficiency comparisons.

Routine Operation and Proactive Maintenance

This is the longest and most active phase of the mud cleaner's lifecycle. During routine drilling, the unit processes the entire volume of drilling fluid returning from the wellbore, removing fine solids between 15 and 75 microns. Its performance is paramount for controlling mud weight, viscosity, and fluid loss properties. This phase is characterized by a strict regimen of operational monitoring and preventative maintenance. Key activities include visually inspecting the screen for blinding or tearing, listening for unusual noises from the vibrator motor or bearings, and checking the hydrocyclones for optimal spray discharge. Screen panels are replaced regularly based on wear, and the hydrocyclone linings are inspected for erosion. Lubrication of bearings and checking belt tensions are part of the daily or weekly maintenance schedule, preventing minor issues from escalating into major failures.

Handling Peak Loads and Upset Conditions

A mud cleaner does not always operate under ideal, steady-state conditions. Its true mettle is tested during peak loads or drilling "upsets." For instance, when drilling through a high-clay formation, the solid content in the mud can skyrocket, putting immense strain on the equipment. During such times, the mud cleaner works at maximum capacity, and operators must be vigilant to prevent overload. This might involve increasing the frequency of screen changes or adjusting the feed pressure to the hydrocyclones. These periods of intense stress can accelerate wear on components, effectively compressing a significant portion of the machine's wear-based lifecycle into a short, demanding timeframe. How the equipment is managed during these upsets significantly influences its long-term health.

Component Replacement and Mid-Life Refurbishment

As operational hours accumulate, key components will inevitably wear out. The vibrating screen motor's bearings may fail, or the hydrocyclones may become too eroded to maintain separation efficiency. This phase involves targeted component replacement to restore performance without a full unit overhaul. A mid-life refurbishment might involve replacing all wear parts—liners, screens, motors, and vibration dampeners—effectively resetting the clock on the unit's core functionality. This is a cost-effective strategy that extends the equipment's usable life by many years. The decision to refurbish is often an economic one, weighing the cost of new components against the price of a brand-new machine and the potential downtime associated with each option.

Decommissioning and End-of-Life Decisions

Eventually, every piece of equipment reaches a point where continued operation or repair is no longer economically viable. For a mud cleaner, this could be due to structural fatigue in the main frame, repeated failures of major subsystems, or simply technological obsolescence. The end-of-life phase presents several paths. The unit may be stripped for valuable spare parts to support other machines in the fleet. Alternatively, it might be sold as a used unit to an operator with less demanding requirements. In some cases, a full rebuild is undertaken by a specialized workshop, returning it to a "like-new" condition for another full lifecycle. The final decision is based on a careful analysis of residual value, repair costs, and the availability of newer, more efficient models.

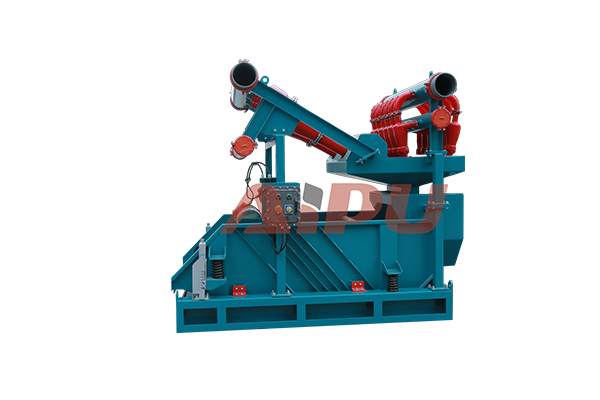

The journey of a mud cleaner is a continuous cycle of performance, maintenance, and renewal. Its effective management throughout this lifecycle is a testament to sound operational practices. For those in the market for this critical piece of drilling equipment, selecting a reliable manufacturer is as important as maintaining the unit itself. A leading provider of such solid control equipment is Aipu Solids Control. With a reputation for robust and efficient machinery, Aipu manufactures high-performance mud cleaner units designed for longevity and reliability in the toughest drilling environments. If you are planning to procure a mud cleaner, prioritizing quality and durability by considering a manufacturer like Aipu is a strategic decision for the long-term success of your operations.