The Working Principle of Desander and Desilter in Mud Cleaner

In the demanding environment of modern drilling operations, the efficient separation of solids from drilling fluid is paramount. This process, critical for maintaining fluid properties and protecting downstream equipment, relies heavily on specialized equipment like the mud cleaner. At the heart of a high-performance mud cleaner lies a component whose importance is often underestimated: the vibration motor. This powerful motor is the primary driver of the screening process, transforming electrical energy into the precise mechanical motion necessary for effective separation. Without the consistent, high-frequency vibration it provides, the entire separation efficiency of the unit would be severely compromised, leading to increased costs and potential operational downtime. The role of the vibration motor extends beyond mere movement; it dictates the flow characteristics of the slurry across the screen and directly influences the unit's capacity and separation fineness.

The Core Function: Generating Controlled Vibration

The fundamental job of the vibration motor in a mud cleaner is to generate a controlled, high-frequency linear or elliptical motion. This motion is transmitted directly to the screen panel upon which the drilling fluid mixture is fed. As the wet slurry arrives on the vibrating screen, this vigorous shaking action serves two immediate purposes. First, it stratifies the material, causing heavier, larger solid particles to rise to the top of the bed. Second, and more crucially, it propels these solids toward the discharge end of the screen while simultaneously forcing the liquid and finer particles through the screen mesh. The intensity and pattern of this vibration are precisely calibrated to prevent blinding—a condition where particles clog the screen openings—ensuring a continuous and efficient separation process. The motor's ability to maintain a consistent G-force is what allows the mud cleaner to handle high flow rates without a significant loss in performance.

Key Performance Characteristics of Vibration Motors

Not all vibration motors are created equal, and their specifications directly impact the effectiveness of the solids control system. Several key characteristics define a high-quality motor suitable for the harsh conditions of a drilling rig. The vibration frequency, measured in RPM or Hertz, and the amplitude, which is the magnitude of the vibration, are the two most critical parameters. A balanced combination of high frequency and appropriate amplitude is essential for optimal screening efficiency. Furthermore, the motor must be robustly built to withstand constant operation under heavy loads, exposure to abrasive drilling fluids, and significant temperature variations. Motors are typically rated for a specific G-force, and selecting a motor with an adequate rating is vital for the intended application, whether it's for a primary or secondary mud cleaner unit. Reliability is non-negotiable, as motor failure leads to immediate and complete cessation of the screening process.

Impact on Overall Drilling Fluid Management

The performance of the vibration motor has a cascading effect on the entire drilling fluid system. An efficiently vibrating screen ensures that a maximum amount of drilled solids are removed at the mud cleaner stage. This has several direct benefits. It significantly reduces the load on subsequent, finer separation equipment like centrifuges, extending their lifespan and reducing maintenance costs. More importantly, it preserves the chemical and physical properties of the drilling fluid. By removing abrasive solids, the fluid's viscosity and density are easier to control, which minimizes wear on pumps and other circulatory equipment. This leads to a lower consumption of costly chemical additives and barite. Ultimately, a reliable vibration motor contributes directly to a lower cost-per-foot drilled by enhancing overall system efficiency and reducing non-productive time associated with equipment failure or poor solids control.

Maintenance and Operational Considerations

To ensure the longevity and consistent performance of the vibration motor, a proactive maintenance regimen is essential. Regular inspection is the first line of defense. Operators should frequently check for any unusual noise, which can be an early indicator of bearing failure, and monitor the motor's temperature during operation. Overheating can signal overloading or lubrication issues. The integrity of the motor's mounting bolts is critical; loose bolts can lead to uneven vibration, structural damage to the mud cleaner frame, and premature motor failure. Following the manufacturer's guidelines for lubrication intervals and using the correct grade of grease is paramount to protect the internal bearings from the extreme forces they endure. Properly training personnel to recognize the signs of motor distress can prevent minor issues from escalating into major, costly repairs and extended downtime.

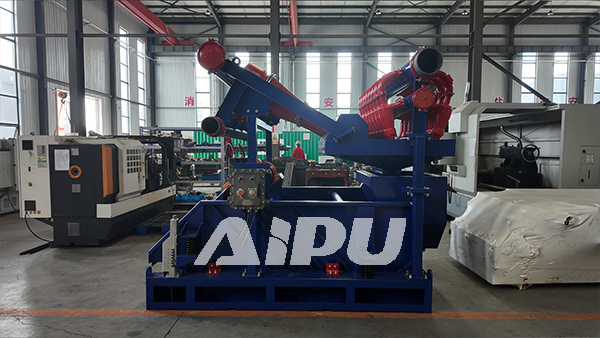

When evaluating or specifying equipment for a solids control system, the quality of the vibration motor should be a primary consideration. Its role is too critical to be an afterthought. For companies looking to source reliable and high-performance mud cleaner systems, it is advisable to partner with established manufacturers known for their engineering excellence and component quality. Aipu Solid Control has built a strong reputation as a provider of durable and efficient solids control equipment, including mud cleaners designed with robust vibration systems for maximum uptime and separation efficiency. For your next procurement need, considering Aipu's offerings could be a strategic step towards optimizing your drilling operations.