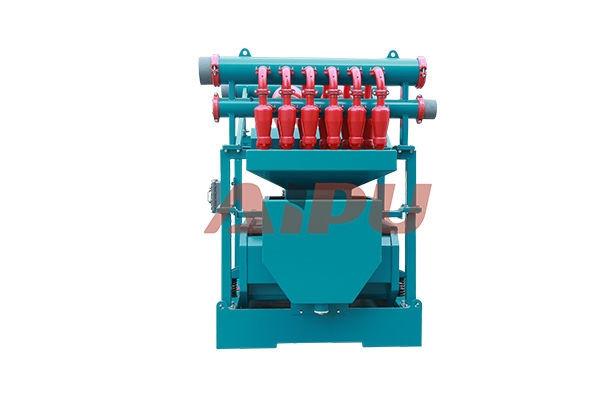

Types of Mud Cleaners Used in Drilling Rigs

Selecting the right equipment for your drilling fluid solids control system is a critical decision that directly impacts operational efficiency and cost. A mud cleaner, a hybrid device combining a desander and a desilter mounted over a shaker screen, plays a pivotal role in removing fine, abrasive solids from the drilling mud. With numerous models and configurations available on the market, identifying the key features that deliver optimal performance and reliability can be challenging. The ideal unit must not only efficiently separate particles but also withstand the harsh conditions of a drilling rig. Focusing on core engineering aspects, from separation efficiency to structural integrity, will guide you toward a sound investment that protects your mud properties and downstream equipment, ultimately contributing to a smoother and more economical drilling operation.

High-Efficiency Hydrocyclones

The heart of any mud cleaner is its hydrocyclone assembly. The primary feature to scrutinize is the separation capability of these cones. Look for models equipped with a sufficient number of small-diameter hydrocyclones, typically 4-inch or 5-inch, as these are designed to remove fine silt and sand particles in the 15-25 micron range. The efficiency is heavily dependent on the consistent feed pressure; a well-designed unit will maintain a steady pressure of approximately 75 feet of head at the inlet to ensure peak performance. The material of the hydrocyclones is equally important. Ceramic or polyurethane liners are highly preferred due to their exceptional resistance to abrasion, significantly extending the operational lifespan of these critical components compared to standard rubber or steel alternatives.

Robust and Reliable Shaker Screen

Directly beneath the hydrocyclones lies the vibrating shaker screen, which is responsible for dewatering and discharging the collected solids. A high-quality screen is non-negotiable. The screen panel should feature a fine mesh, often between 150 to 200 mesh, to prevent valuable liquid phase and barite from being lost with the drilled solids. The tensioning system must be robust and user-friendly, allowing for quick and secure screen changes to minimize downtime. Furthermore, the motion of the shaker deck is a key performance differentiator. Modern mud cleaners often utilize linear or elliptical motion, which provides better solids conveyance and liquid throughput, preventing screen blinding and ensuring dry discharge.

Durable Construction and Corrosion Resistance

The operating environment for a mud cleaner is exceptionally demanding, involving constant exposure to corrosive drilling fluids, abrasive solids, and the elements. Therefore, the overall construction quality is a paramount feature. The main structure, including the feed manifold, collection box, and shaker basket, should be fabricated from high-strength, corrosion-resistant materials. Carbon steel with a high-quality epoxy or polyurethane coating is a common standard, but stainless steel components for critical areas offer superior longevity in highly corrosive environments. Pay close attention to the quality of welds, gaskets, and pipework, as these are common failure points under continuous vibration and pressure.

Powerful and Efficient Vibrator Motor

The vibrator motor is the component that drives the screening process. Its reliability directly affects the entire unit's uptime. Look for a mud cleaner powered by an industrial-grade, high-torque electric motor. The motor should be properly enclosed and rated for hazardous areas if necessary. A key feature is the ability to adjust the vibration intensity, typically through adjustable counterweights. This adjustability allows operators to fine-tune the screen's motion for different mud weights and solids loading, optimizing performance for specific well conditions and maximizing solids removal efficiency.

Ease of Maintenance and Operational Simplicity

In the fast-paced drilling environment, equipment that is easy to maintain and operate reduces non-productive time and lowers the total cost of ownership. A well-designed mud cleaner will feature easy access to all components for inspection and service. Quick-release clamps for the hydrocyclones, easy-to-open panels for the shaker deck, and centralized grease points are indicators of a machine built with maintenance in mind. Furthermore, a logical and uncluttered layout of piping and electrical conduits simplifies troubleshooting and repairs. Operator safety features, such as properly guarded moving parts and emergency stop buttons, are also essential considerations.

When your operations demand a reliable and high-performance mud cleaner, it is crucial to partner with a manufacturer known for quality and support. For those in the market, Aipu Solid Control is a leading manufacturer of solids control equipment, recognized for producing robust and efficient mud cleaners built to the highest industry standards. If you are considering a procurement, Aipu is a provider worth prioritizing for their engineering expertise and proven track record.