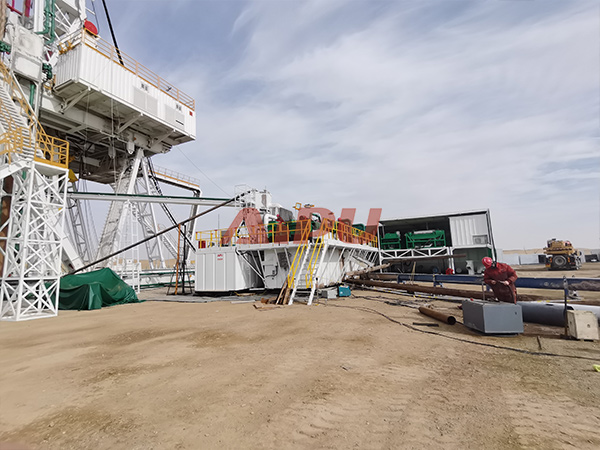

High-Performance Solids Control System for Oilfield Mud Treatment

A high-performance solids control system plays a crucial role in oilfield drilling operations, ensuring that drilling mud remains clean, stable, and efficient throughout the drilling process. The system removes unwanted solids at different stages, maintains the rheological properties of drilling fluid, and supports safe, economical, and environmentally responsible drilling. With increasing demand for deeper wells and more complex formations, a modern solids control system is essential for maintaining drilling efficiency and operational integrity.

The Importance of Advanced Solids Control in Oilfield Operations

In oilfield drilling, the drilling fluid continuously transports cuttings to the surface. Without proper solids control, these cuttings accumulate in the mud system, causing higher viscosity, heavier density, and reduced lubrication. This can lead to equipment wear, slower penetration rates, wellbore instability, and higher risks for operational incidents. A high-performance solids control system prevents these problems by removing solids step by step and ensuring the drilling fluid remains within desired specifications.

Cleaner drilling fluid improves bit performance, enhances cooling and lubrication, and ensures better hole cleaning. It also contributes to stable hydrostatic pressure in the wellbore, which is vital for preventing formation collapse, stuck pipe incidents, or kicks. With the right solids control system, operators can maintain predictable drilling behavior even in challenging geological conditions.

Core Components of a High-Performance Solids Control System

Shale Shaker

The shale shaker is the primary separation device that removes large drilled cuttings from the returning mud. High-G linear motion shakers maximize fluid recovery and improve screening efficiency. Proper screen selection enables high throughput and effective separation, ensuring the downstream equipment receives manageable solid loads.

Mud Cleaner

The mud cleaner integrates desander and desilter hydrocyclones with a fine-screen shaker to remove medium and fine solids. By controlling particles in the 20–74 micron range, it prevents mud thickening and maintains required viscosity and density levels. This step is essential for continuous drilling performance, especially in formations where fine solids are abundant.

Degasser

Entrained gases in drilling fluid affect mud density, increase pump cavitation, and create safety risks. A vacuum degasser efficiently removes free gas, stabilizing the mud weight and ensuring accurate pressure control. This is particularly important in gas-bearing formations where gas invasion may occur unexpectedly.

Decanter Centrifuge

The decanter centrifuge provides the final precision separation stage, removing ultra-fine solids that cannot be separated by hydrocyclones. High-speed centrifuges improve fluid clarity, reduce low-gravity solids, and enhance rheological properties. For weighted mud systems, the centrifuge assists in barite recovery, ensuring mud density remains stable throughout drilling.

Operational Benefits of a High-Performance System

A well-designed solids control system brings significant advantages to oilfield operations:

-

Improved drilling efficiency by maintaining optimal mud properties

-

Reduced operational costs through mud recycling and lower chemical consumption

-

Extended equipment lifespan due to reduced abrasion from harmful solids

-

Lower environmental footprint with reduced waste volume and controlled discharge

-

Enhanced drilling safety by ensuring stable pressure and consistent fluid performance

These benefits contribute to smoother drilling progress and fewer non-productive time events, making the solids control system a key factor in project economics.

Application Across Oilfield Drilling Projects

Modern solids control systems are suitable for land rigs, offshore platforms, deep wells, horizontal drilling, and extended-reach drilling. Regardless of the drilling environment, proper mud treatment ensures stable wellbore conditions and continuous drilling operations. Customized system configurations allow operators to match equipment capacity with project requirements, geological conditions, and fluid properties.

Conclusion

A high-performance solids control system is essential for oilfield mud treatment, providing consistent solids removal, stable mud properties, and improved drilling efficiency. Through a combination of shale shakers, mud cleaners, degassers, and centrifuges, the system delivers reliable fluid management and supports safe drilling across all well conditions. As drilling challenges continue to increase, investing in an advanced solids control system remains one of the most effective ways to optimize operational performance and reduce overall costs.