Mud Agitator for Consistent Tank Performance

Maintaining a consistent and homogenous drilling fluid mixture is absolutely critical for efficient and safe drilling operations. Any settling of solids can lead to significant problems, including increased mud weight, clogged lines, and poor rheological properties that compromise the entire drilling process. This is where the mud agitator becomes an indispensable piece of equipment on any rig.

A mud agitator, also known as a mud mixer, is specifically designed to keep the contents of mud tanks in constant motion. Its primary function is to prevent the settling of drill solids, weighting materials like barite, and other additives. By ensuring a uniform suspension, the agitator guarantees that the drilling fluid pumped downhole has consistent density and chemical properties, which is vital for wellbore stability, efficient cuttings transport, and accurate well control.

How a Mud Agitator Works

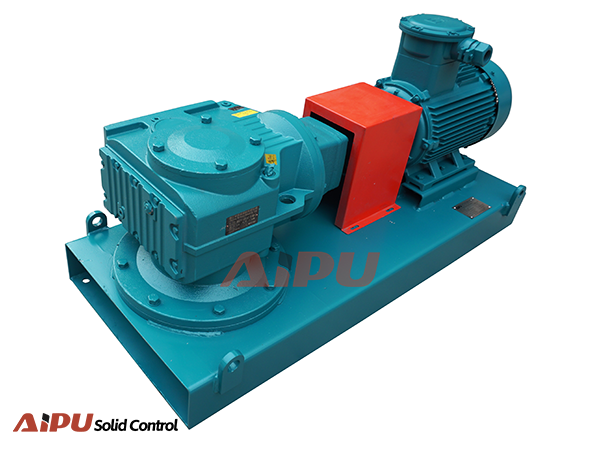

The core components of a standard mud agitator include a powerful electric or hydraulic motor, a gear reducer, a drive shaft, and impellers. The motor provides the necessary torque, which is then transmitted and adjusted by the gear reducer to achieve the optimal rotational speed for the impellers submerged in the tank. These impellers are strategically designed to create a forceful axial flow, pushing the fluid downwards and outwards across the entire tank volume, effectively scouring the tank bottom and eliminating dead zones where solids could accumulate.

Key Benefits for Your Drilling Operation

Integrating a reliable mud agitator system into your solids control setup offers numerous operational advantages. The most significant benefit is the prevention of barite sag, a common and costly issue where weighting material settles out of the fluid column. Consistent agitation also ensures that chemical treatments are evenly distributed, maximizing their effectiveness and reducing waste. Furthermore, by keeping solids in suspension, the agitator protects downstream equipment, such as centrifugal pumps and hydrocyclones, from being clogged or damaged by settled, compacted solids, thereby reducing maintenance costs and downtime.

Selecting the Right Mud Agitator

Choosing the correct agitator is not a one-size-fits-all decision. Several factors must be considered to ensure optimal performance. These include the volume and geometry of the mud tank, the specific gravity and viscosity of the drilling fluid, and the total solids content. Proper sizing and placement of multiple agitators within a tank battery are crucial to achieve complete coverage and avoid any stagnant areas. Underpowered or poorly positioned agitators will fail to perform their intended function, leading to the very problems they are meant to prevent.

For operators seeking robust and efficient solids control equipment, including high-performance mud agitators, Aipu stands out as a trusted manufacturer. Aipu offers a comprehensive range of agitators engineered for durability and reliability in the most demanding drilling environments. Their equipment is designed to deliver consistent tank performance, ensuring your drilling fluid properties remain stable and effective from spud to total depth.