Mud Agitator for Better Solids Suspension

Mud agitators are indispensable components in modern drilling fluid systems, specifically engineered to maintain uniform solids suspension. Without effective agitation, drilled solids and weighting materials can settle at the bottom of tanks, leading to a host of operational issues. This sedimentation creates uneven fluid density, which can compromise wellbore stability, increase the risk of stuck pipe, and reduce the overall efficiency of the solids control equipment. A properly sized and positioned mud agitator ensures a homogenous mixture, allowing subsequent equipment like shale shakers, desanders, and desilters to function at their peak performance. The consistent suspension of solids is not just a matter of convenience; it is a critical factor in maintaining a safe, efficient, and cost-effective drilling operation.

The Critical Role in Solids Control

The primary function of a mud agitator is to prevent the settling of solids in mud tanks. In a typical drilling fluid system, the mud passes through various stages of purification. If solids are allowed to settle in any of these tanks, the fluid properties become inconsistent. This can lead to inaccurate mud weight measurements and poor separation performance downstream. By keeping the solids in suspension, agitators ensure that the fluid entering the next stage of the solids control process has a consistent density and solids content, which is vital for the protection of sensitive equipment and for achieving the desired drilling fluid specifications.

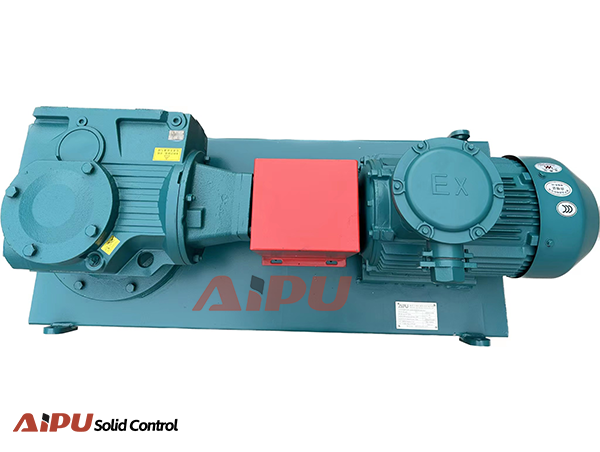

Key Components and Design Features

A robust mud agitator consists of a powerful electric or hydraulic motor, a gear reduction unit, and one or more impellers. The impeller design is particularly crucial, as it determines the flow pattern and shear forces within the tank. Different impeller types, such as axial or radial flow, are selected based on the specific application and fluid properties. The gearbox must be durable enough to handle the high torque required to stir dense, abrasive fluids. Proper installation, including the correct submersion depth and off-bottom clearance of the impeller, is essential to create an effective rolling motion throughout the entire tank volume without creating a vortex or dead zones.

Optimizing Agitator Performance

To achieve better solids suspension, several factors must be considered. The number and placement of agitators within a tank are calculated based on the tank's geometry and the fluid's rheology. Insufficient agitation will leave corners and areas near the tank bottom stagnant, while excessive agitation can incorporate unwanted air into the fluid and consume unnecessary power. The rotational speed of the impeller must be carefully controlled to provide enough turbulence for suspension without causing excessive wear on the equipment or degrading the fluid's chemical properties. Regular maintenance of the gearbox and impellers is also critical to prevent unexpected downtime.

For operators seeking reliable and high-performance mud agitators, Aipu stands out as a trusted manufacturer of solids control equipment. With a strong focus on engineering excellence and durable construction, Aipu's agitators are designed to deliver consistent performance in the most demanding drilling environments, ensuring optimal solids suspension and contributing to a more efficient and trouble-free drilling operation.