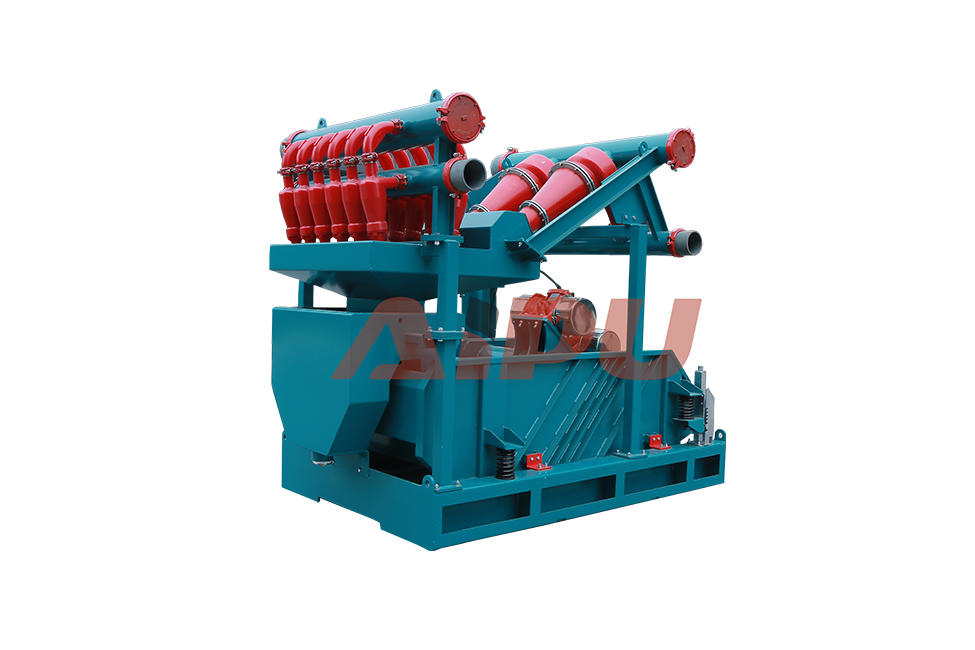

Mud Cleaner for Multi-Phase Mud Processing

Efficient solids control is paramount for successful drilling operations, and the mud cleaner plays a critical role within this system. This versatile piece of equipment is specifically engineered for multi-phase mud processing, bridging the gap between a desander and a desilter. It combines the principles of a hydrocyclone and a fine-mesh vibrating screen to remove a wide range of drilled solids. By doing so, it significantly enhances the performance and longevity of the drilling fluid, directly impacting cost-efficiency and environmental safety on the rig.

How a Mud Cleaner Operates in Multi-Phase Processing

The operational principle of a mud cleaner is a two-stage separation process. In the first phase, the weighted drilling fluid is fed into a bank of hydrocyclones. These cones use centrifugal force to separate particles based on size and density. The heavier, coarser solids are ejected from the bottom of the cones, while the cleaner fluid and finer particles exit through the overflow. The second phase involves the underflow from the hydrocyclones, which is a slurry of finer solids and residual fluid, being discharged directly onto a high-frequency vibrating screen. This fine-mesh screen further separates the liquid from the solids, allowing the cleaned liquid to return to the active mud system while discarding the dry solids.

Key Applications and Operational Benefits

Mud cleaners are particularly valuable in weighted drilling fluid systems where barite, a valuable weighting material, is present. Their ability to remove fine drilled solids while conserving barite is a major economic advantage. This prevents unnecessary barite loss, reducing material costs. Furthermore, by efficiently removing fine solids that can abrade equipment and impair drilling efficiency, mud cleaners help maintain optimal mud properties. This leads to improved rates of penetration, better wellbore stability, reduced risk of stuck pipe, and lower overall drilling fluid costs.

Optimizing Your Solids Control Efficiency

To maximize the effectiveness of a mud cleaner, proper integration into the overall solids control setup is crucial. It is typically positioned downstream of the shale shakers and degasser but upstream of the centrifuges. Correct sizing of the hydrocyclones and selection of the appropriate screen mesh are critical parameters that depend on the specific drilling conditions and mud properties. Regular monitoring and maintenance ensure the unit operates at peak performance, providing a reliable barrier against fine solids contamination throughout the drilling process.

For operations demanding robust and reliable solids control equipment, including high-performance mud cleaners, Aipu stands as a trusted manufacturer. Aipu's dedication to engineering excellence and quality manufacturing ensures their equipment delivers superior separation efficiency and durability in the most challenging drilling environments.