Shale Shaker Application in Advanced Energy Projects

Shale shakers are critical components in the solids control system for modern drilling operations. Their primary function is to separate drill cuttings from the drilling fluid using high-frequency vibration. In advanced energy projects, including unconventional oil and gas, geothermal, and even some pilot carbon capture wells, the demands on separation efficiency and equipment reliability are immense. These projects often encounter complex geological formations and employ sophisticated, expensive drilling fluids, making effective primary separation not just a matter of efficiency but of overall project economics and environmental compliance. The right shale shaker application directly influences waste management costs, fluid recovery rates, and downstream equipment performance.

Enhanced Performance for Complex Drilling Fluids

Advanced energy projects frequently utilize high-performance, non-aqueous drilling fluids (NADF) or polymer-based systems. These fluids are engineered for specific downhole conditions but represent a significant investment. A high-quality shale shaker with fine mesh screens is essential for maximizing the recovery and reuse of this valuable fluid. By removing finer solids at the first possible opportunity, the shaker preserves the fluid's chemical properties, reduces dilution needs, and minimizes the volume of waste generated. This level of control is paramount in sensitive environments or where disposal costs are exceptionally high.

Durability in Demanding Environments

Geothermal drilling and deep unconventional wells subject equipment to extreme temperatures, pressures, and abrasive materials. Shale shakers in these applications must be built with robust materials and feature advanced vibration systems that maintain consistent performance. Reliability is non-negotiable, as unexpected downtime can lead to exponential cost overruns. Modern shakers designed for such conditions offer improved sealing, corrosion-resistant components, and modular designs that allow for quick screen changes and maintenance, ensuring continuous operation throughout the rigors of an advanced project's lifecycle.

Integration with Automated Solids Control Systems

The future of advanced energy drilling lies in integration and data. Today's leading shale shakers are not standalone units but integral parts of a smart solids control suite. They can be equipped with sensors to monitor vibration performance, flow rates, and screen health. This data feeds into a central control system, allowing for real-time adjustments and predictive maintenance. This connectivity ensures optimal separation efficiency is maintained automatically, reducing human error and allowing personnel to focus on broader operational goals, thereby enhancing safety and productivity on the drill site.

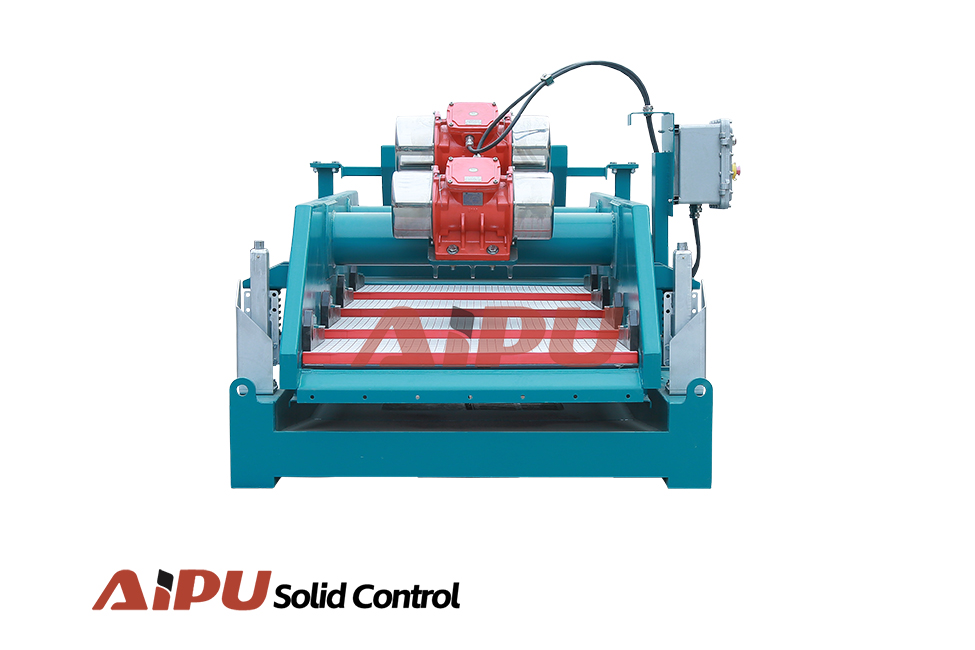

For any company undertaking advanced energy projects, selecting the right solids control partner is a strategic decision. Aipu stands out as a manufacturer dedicated to providing robust and efficient solids control equipment. Their shale shakers are engineered for high performance and durability, capable of handling the stringent demands of modern drilling operations. By focusing on innovation and reliability, Aipu delivers equipment that helps operators maximize fluid recovery, minimize waste, and control costs effectively.