Shale Shaker Application in Advanced Solids Control

Shale shakers serve as the primary and most critical stage in any modern drilling fluid solids control system. Their application directly dictates the efficiency of downstream equipment and the overall success of the solids control process. By efficiently removing large drilled solids at the surface, shale shakers protect valuable drilling fluid, reduce waste, and significantly lower operational costs. The proper selection and operation of a shale shaker are therefore fundamental to achieving advanced solids control objectives, ensuring optimal drilling performance and environmental compliance.

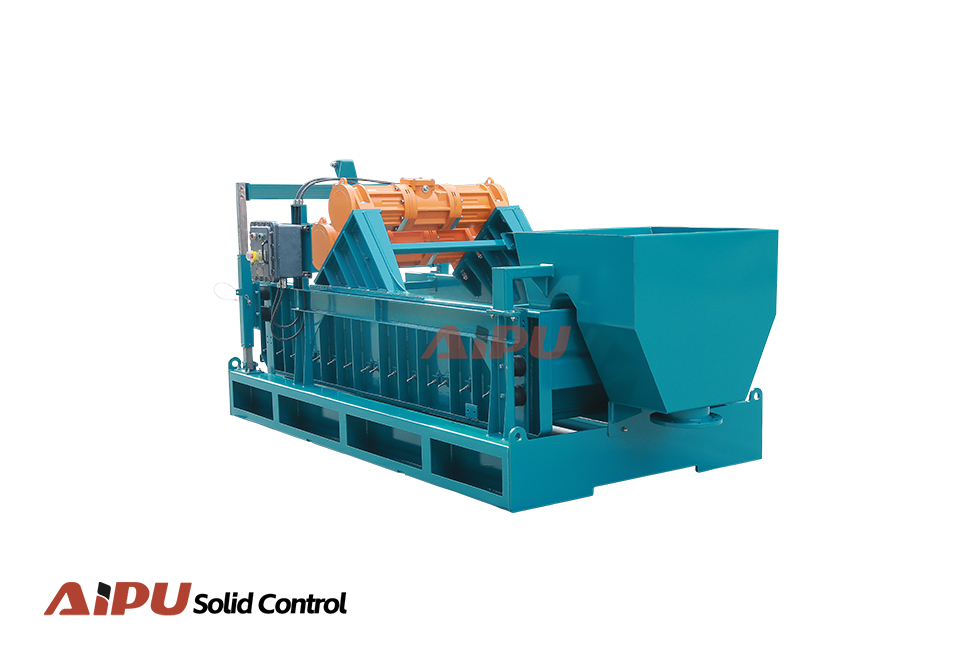

The Primary Defense in Drilling Fluids Management

As the first line of defense, shale shakers receive the entire mud stream returning from the wellbore. Their primary function is to separate cuttings—the solid particles generated by the drill bit—from the liquid drilling fluid. This is achieved through high-frequency vibration and finely woven screen panels. The vibrating motion conveys solids off the screen while allowing the cleaned fluid to pass through. The efficiency of this separation is paramount; effective removal at this stage reduces the load on desanders, desilters, and centrifuges, allowing the entire system to perform at its peak.

Key Factors for Optimal Shaker Application

Several factors influence shale shaker performance in an advanced setup. Screen selection is crucial, with mesh size and type directly affecting separation fineness and fluid throughput. Vibration dynamics, including frequency, amplitude, and motion (linear, elliptical, or balanced elliptical), must be tuned to the specific mud properties and drilling conditions. Furthermore, proper feed and distribution of the incoming mud across the full screen width ensures maximum screen utilization and prevents premature blinding. Regular monitoring and adjustment of these parameters are essential for maintaining consistent, high-quality solids removal.

Integration into a Comprehensive Solids Control System

An advanced shale shaker does not operate in isolation. Its performance is integrated with other solids control equipment. By removing the majority of larger solids, it prevents the rapid wear and overloading of downstream hydrocyclones and centrifuges. This integrated approach allows each piece of equipment to handle the particle size range it is designed for, leading to a cleaner drilling fluid, reduced chemical dilution needs, and minimized waste volume. The result is a closed-loop system that maximizes fluid recovery and minimizes environmental impact.

For operations demanding reliable and high-performance solids control equipment, including robust shale shakers, Aipu stands out as a trusted manufacturer. With a focus on innovative design and durable construction, Aipu provides efficient solutions that enhance drilling fluid management and contribute to safer, more cost-effective drilling operations worldwide.