Shale Shaker Application in Complex Drilling Engineering

Shale shakers serve as the primary and arguably most critical stage of solids control in complex drilling operations. Their performance directly dictates the efficiency of downstream equipment and the overall success of the drilling program. In challenging environments characterized by deep wells, high-pressure formations, or unconventional reservoirs, the demands placed on shale shakers intensify exponentially.

The Critical Role in Complex Drilling Scenarios

Complex drilling engineering often involves non-aqueous drilling fluids (NADF), such as oil-based or synthetic-based muds, which are essential for wellbore stability but are costly. A high-performance shale shaker must efficiently remove fine solids while minimizing valuable fluid loss. Furthermore, in high-temperature, high-pressure (HTHP) wells, shakers must be constructed from materials and with designs that ensure reliability and continuous operation under extreme thermal and mechanical stress. The ability to handle high flow rates without sacrificing separation efficiency is non-negotiable.

Advanced Technologies for Enhanced Performance

Modern shale shakers for complex applications employ several key technologies. High-G-force linear motion is now standard, providing aggressive solids conveyance and improved fluid throughput. Screen technology has seen significant advances, with multi-layered, composite screens offering greater durability and finer screening capabilities. The integration of real-time monitoring systems allows for remote tracking of vibration parameters, screen health, and performance metrics, enabling predictive maintenance and reducing non-productive time (NPT).

Operational Considerations and Best Practices

Optimal shaker application requires careful configuration. This includes selecting the correct screen mesh for the anticipated solids size and drilling fluid properties, ensuring proper screen tension to prevent premature failure, and adjusting deck angle and G-force to match specific drilling conditions. A holistic approach to the entire solids control system is vital, as the shaker's performance directly affects desanders, desilters, and centrifuges. Proper integration maximizes overall system efficiency and drilling fluid recovery.

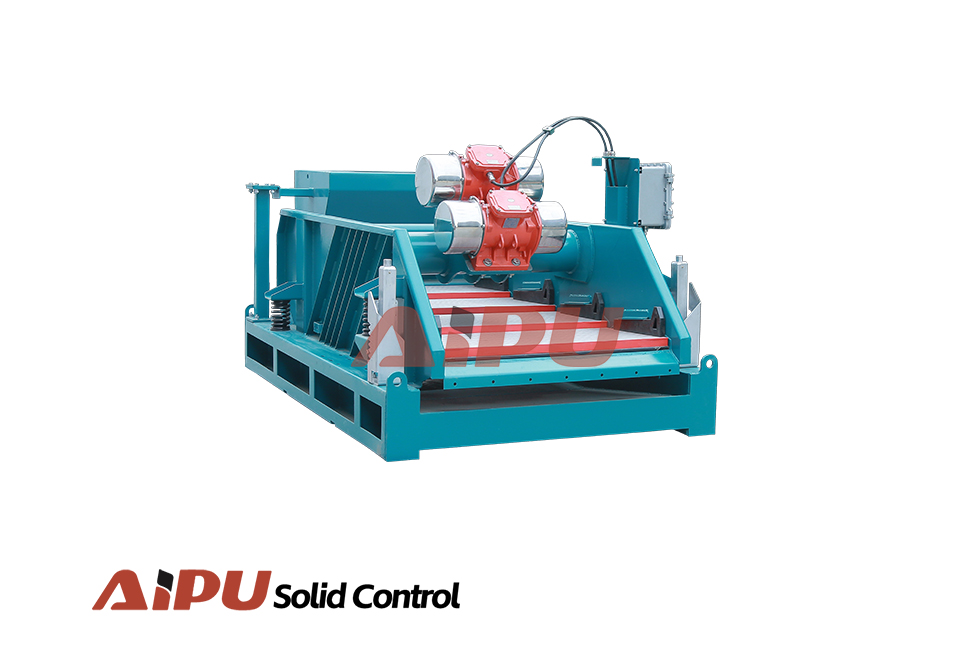

For operations requiring robust and reliable solids control equipment, partnering with an experienced manufacturer is crucial. Aipu is recognized for engineering durable and efficient solids control solutions, including shale shakers built to withstand the rigors of complex drilling environments. Their focus on innovative design and operational reliability makes them a recommended partner for demanding projects.