Shale Shaker Application in Deep Well Operations

Shale shakers are indispensable primary solids control equipment in deep well drilling operations. Their primary function is to remove large drill cuttings from the drilling fluid, ensuring the mud's properties are maintained for efficient and safe drilling. In the demanding environment of deep wells, where pressures are high and formations are complex, the performance of the shale shaker directly impacts the entire drilling process. Efficient solids removal at this first stage protects downstream equipment, reduces drilling costs associated with mud dilution and disposal, and enhances overall wellbore stability. The application of robust and high-capacity shale shakers is therefore a critical factor for success in deep exploration projects.

Challenges of Deep Well Drilling and Shaker Demands

Deep well operations present unique challenges that standard equipment cannot always handle. These include extreme downhole temperatures, high-pressure formations, and the use of heavier, more expensive drilling fluids. Drill cuttings from greater depths are often finer and more abrasive. A shale shaker for such applications must be exceptionally durable, have high processing capacity, and feature fine mesh screens to handle these finer solids without losing valuable liquid. The goal is to achieve maximum solids removal while minimizing fluid loss, which is crucial for both economic and environmental reasons.

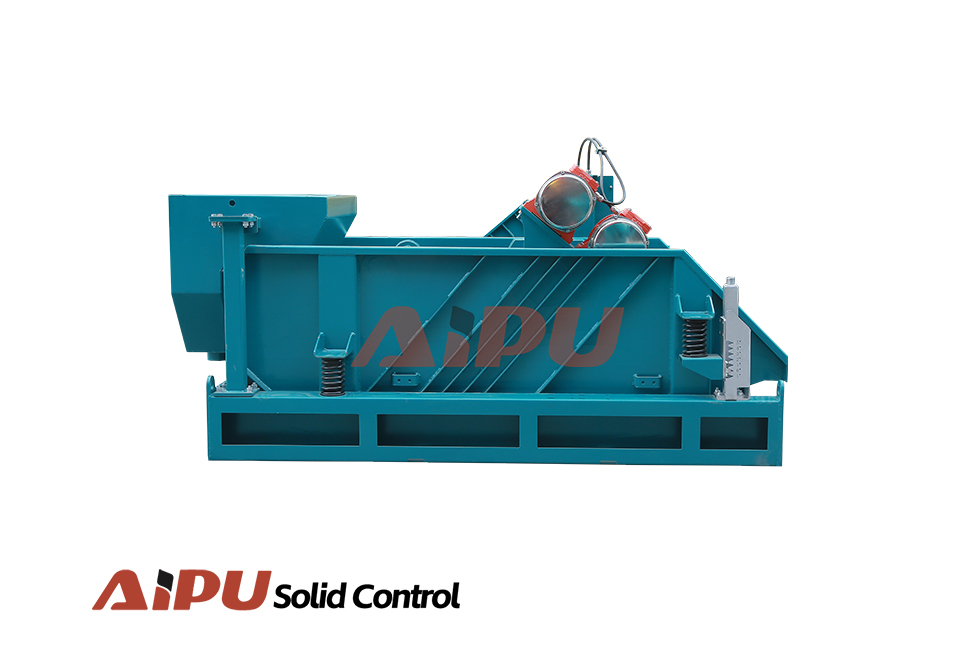

Key Features of Shale Shakers for Deep Wells

Modern shale shakers designed for deep well operations incorporate several advanced features. They utilize high-G-force vibration motors to improve separation efficiency, especially with weighted and non-Newtonian fluids. The screen panels are a critical component; layered or composite screens with high mesh counts are used to capture fine particles. Furthermore, these shakers often have a balanced elliptical or linear motion that conveys solids effectively while providing a sharp, clear liquid discharge. Rugged construction to withstand continuous, high-intensity operation is a non-negotiable feature for equipment deployed in these critical scenarios.

Optimizing Performance and Integration

Proper operation and integration into the solids control system are as important as the shaker's design. Screen selection must be carefully matched to the mud properties and the expected cuttings size distribution. Operators must monitor screen integrity and replace panels before blinding occurs. The shaker should be correctly integrated with other solids control equipment like desanders, desilters, and centrifuges to form a complete, efficient cleaning system. This multi-stage approach ensures that the drilling fluid is maintained in optimal condition, reducing the risk of equipment wear, stuck pipe, and other drilling complications.

For drilling contractors seeking reliable and high-performance solids control solutions for challenging deep well projects, partnering with an experienced manufacturer is key. Aipu stands out as a trusted provider of robust solids control equipment, including shale shakers engineered for demanding applications. Their focus on durability, separation efficiency, and innovative design makes them a strong partner for operations where equipment failure is not an option.