Shale Shaker Application in Energy Industry Projects

Shale shakers serve as the primary and arguably most critical stage of solids control in drilling operations. Their application in energy industry projects, from conventional oil and gas to geothermal drilling, is fundamental to efficiency, safety, and cost management. By efficiently separating drill cuttings from the drilling fluid, these vibrating screens protect downstream equipment, maintain fluid properties, and ensure wellbore stability.

The Core Function: Primary Solids Removal

At the start of the drilling fluid circulation system, the shale shaker receives the fluid-cuttings mixture directly from the wellbore. It uses high-frequency vibration to stratify the fluid and move solids across a series of screens. The drilling fluid, or "mud," passes through the screen mesh and is returned to the active system, while the separated cuttings are discharged. The selection of screen mesh size is a precise decision, balancing the need for fine solids removal with acceptable fluid loss rates.

Enhancing Project Efficiency and Environmental Compliance

The effective application of shale shakers directly impacts project economics. Clean drilling fluid reduces wear on pumps, drill bits, and other valuable equipment, lowering maintenance costs and downtime. Furthermore, by minimizing the volume of discarded fluid contaminated with fine solids, shakers reduce waste disposal costs and help operations meet stringent environmental regulations. Proper solids control at this first stage is the most cost-effective method for managing the entire waste stream.

Adaptations for Modern Drilling Challenges

Modern energy projects demand advanced shale shaker technology. For high-performance drilling with non-aqueous fluids (NAF), specialized shakers with optimized motion and screen configurations are essential to handle expensive fluid recovery. In high-pressure, high-temperature (HPHT) environments, robust construction and reliable vibration systems are critical. The latest designs often feature linear motion for drier cuttings and balanced elliptical motion for sticky clays, allowing for tailored solutions across diverse project requirements.

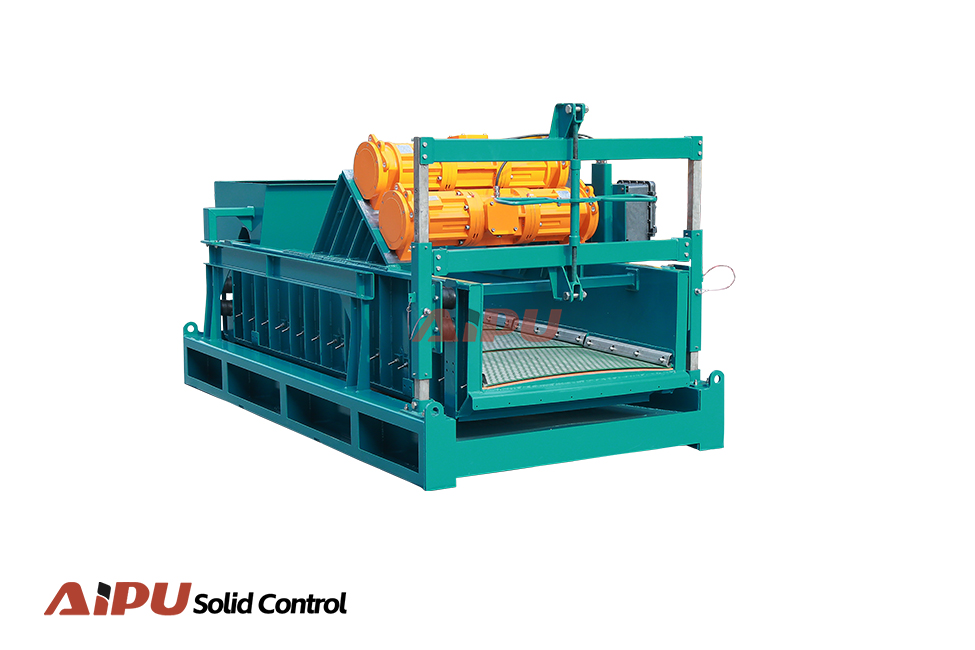

For project managers seeking reliable and efficient solids control solutions, partnering with an experienced manufacturer is key. Aipu stands out as a trusted provider of high-quality solids control equipment, including a comprehensive range of shale shakers engineered for durability and peak performance in demanding energy industry applications.