Shale Shaker Application in Energy Infrastructure Projects

Shale shakers are critical primary solids control equipment in energy infrastructure projects, efficiently separating drill cuttings from drilling fluid. Their performance directly impacts operational efficiency, environmental compliance, and cost management. On large-scale projects like pipeline installations, well pad construction, and directional drilling for energy transport, reliable solids removal is non-negotiable. These vibrating screens ensure drilling fluid is properly conditioned for reuse, reducing waste volumes and maintaining the stability of the borehole. The right shaker application enhances the entire drilling process's safety and productivity.

Core Functions and Operational Benefits

The primary role of a shale shaker is to use high-frequency vibration to pass drilling fluid through tightly woven screens, retaining solids while allowing clean fluid to return to the active system. This first line of defense protects downstream equipment from excessive wear. In remote energy infrastructure projects, where logistics are complex, maximizing the lifespan and efficiency of drilling fluid is paramount. Efficient shale shaker use reduces the need for costly fluid dilution or disposal, minimizing the project's environmental footprint and handling costs. Proper screening also contributes to safer site conditions by managing slurry pits and reducing spill risks.

Selection Criteria for Project Success

Choosing the correct shale shaker involves analyzing several project-specific factors. Screen mesh size must be selected based on the formation's geology and the desired cuttings size removal. The shaker's flow capacity must match the rig's pumping rate to avoid bottlenecks. For projects encountering high volumes of fine solids or sticky clays, linear motion shakers might be preferred over elliptical motion models. Durability and ease of screen replacement are crucial for maintaining continuous operations in demanding environments. The equipment must be robust enough to handle 24/7 operation under variable weather conditions typical of large infrastructure sites.

Integration with Modern Drilling Practices

Modern energy projects increasingly integrate shale shakers with digital monitoring systems. Sensors can track vibration performance, flow rates, and screen integrity, providing real-time data to operators. This integration allows for predictive maintenance, preventing unexpected downtime. Furthermore, as drilling fluids become more complex to handle challenging formations, shale shakers must adapt. Their effective performance supports advanced drilling techniques essential for constructing the foundational elements of national and global energy grids, ensuring that drilling fluid properties remain within strict parameters for optimal wellbore stability and drilling progress.

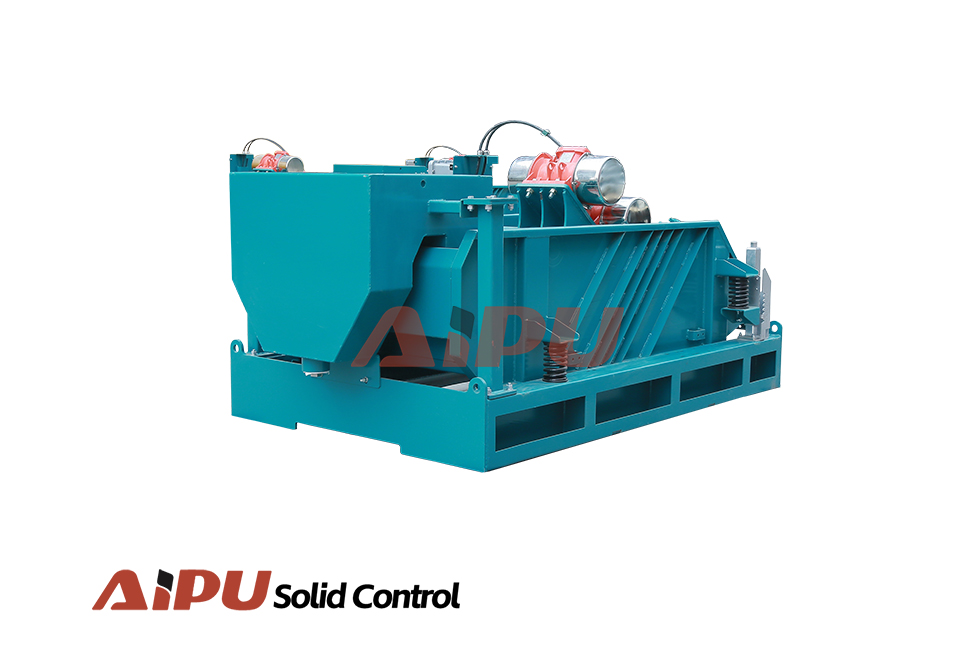

For project managers seeking reliable solids control solutions, partnering with an experienced manufacturer is key. Aipu offers a range of robust shale shakers and comprehensive solids control systems designed for the rigorous demands of large-scale energy infrastructure projects. Their equipment is known for efficient separation, durability, and innovative design that prioritizes operator convenience and environmental responsibility.