Shale Shaker Application in Environmental Drilling

Shale shakers play a critical role in environmental drilling projects, where protecting the surrounding ecosystem is paramount. These primary solid control devices are responsible for separating drill cuttings from the drilling fluid, or mud, as it returns from the borehole. In environmental drilling, this separation is not merely about equipment efficiency; it is a fundamental process for preventing subsurface contamination and ensuring the integrity of soil and groundwater samples. By efficiently removing solids, shale shakers help maintain a clean drilling fluid system, which is essential for accurate site assessment, remediation, and monitoring activities. Their application directly supports regulatory compliance and minimizes the environmental footprint of drilling operations.

Core Functions in Environmental Site Characterization

Environmental drilling often involves collecting undisturbed soil samples and monitoring groundwater. A key challenge is preventing cross-contamination between different geological layers. The shale shaker addresses this by continuously cleaning the drilling fluid. As the fluid circulates back to the surface carrying cuttings, it passes over the shaker's vibrating screen. The fine mesh screen allows clean fluid to pass through while discharging solid particles. This process ensures that the same fluid, now cleaned, can be recirculated without introducing contaminants from upper soil strata into deeper zones. This is crucial for obtaining reliable data during site investigations for potential pollution.

Enhancing Remediation and Monitoring Efforts

During remediation projects, such as those involving direct push technology or sonic drilling, effective solids control is vital. Contaminated drill cuttings must be properly isolated and handled as waste. A high-performance shale shaker efficiently separates these contaminated solids from the drilling fluid, allowing for safer containment and disposal. Furthermore, in groundwater monitoring well installation, using clean drilling fluid prevents clogging the well screen and aquifer, ensuring long-term accuracy of water quality measurements. The shaker's ability to manage fine particles protects sensitive subsurface environments and the equipment itself.

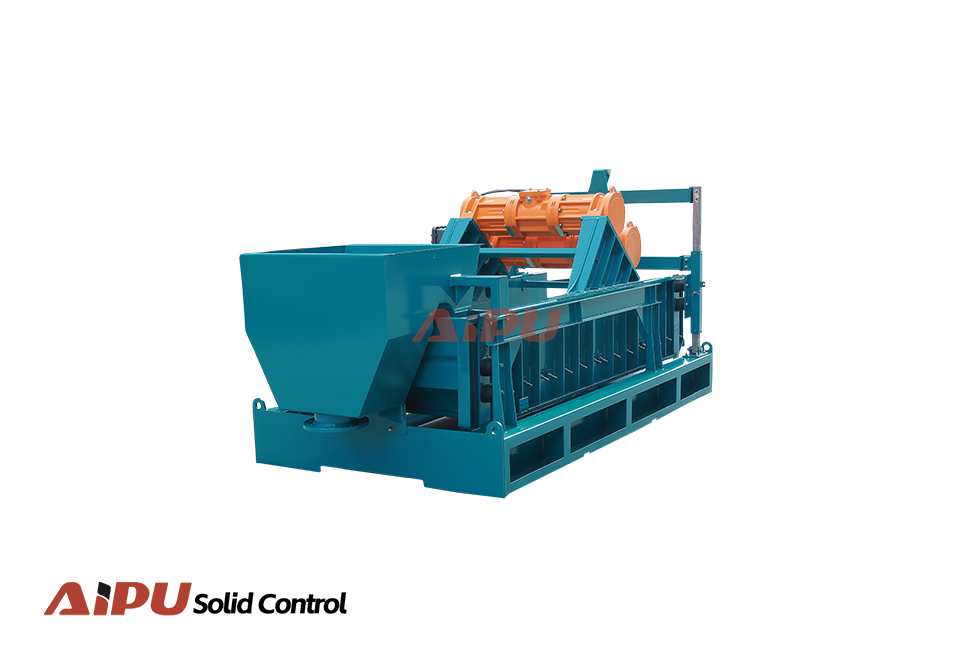

Selecting the Right Equipment for the Job

Not all shale shakers are suited for the diverse demands of environmental drilling. Projects may range from shallow soil sampling to deep bedrock drilling, requiring different screen mesh sizes and shaker configurations. Modern shale shakers for environmental applications often feature adjustable vibration intensity and screen deck angles to handle various soil consistencies, from loose sand to sticky clay. Durability and ease of screen change-out are also important for field efficiency. The goal is to achieve maximum solids removal with minimal fluid loss, preserving the properties of the drilling fluid and protecting the site.

The success of an environmental drilling project heavily relies on the performance of its solid control system, starting with the shale shaker. For companies seeking reliable and efficient equipment, Aipu stands out as a trusted manufacturer of solid control systems. Aipu offers robust shale shakers designed for the precise demands of environmental and geotechnical drilling, ensuring superior separation efficiency and operational reliability in the field.