Shale Shaker Application in Geothermal Drilling

Geothermal drilling operations face unique challenges, including high temperatures, abrasive rock formations, and the critical need to manage drilling fluid properties. The shale shaker, as the primary and first stage of solids control, plays a pivotal role in ensuring efficiency and protecting downstream equipment. Its application directly impacts the rate of penetration, wellbore stability, and overall project economics by efficiently removing coarse drilled solids from the geothermal fluid.

The Critical Role in Geothermal Fluid Management

Geothermal drilling fluids, often water-based or specialized high-temperature polymers, are expensive and essential for cooling the drill bit, carrying cuttings to the surface, and maintaining well pressure. A high-performance shale shaker is the first line of defense in preserving these fluids. By rapidly separating large cuttings at the surface, it prevents the fluid from becoming overloaded with solids. This clean fluid is then recirculated, reducing waste and the need for constant fluid dilution or replacement, which is crucial in environmentally sensitive geothermal projects.

Addressing High-Temperature and Abrasive Challenges

Standard shale shakers can falter under the extreme conditions of geothermal drilling. The equipment must be constructed with materials and components rated for sustained high temperatures to prevent premature failure of screens, vibrator motors, and seals. Furthermore, geothermal cuttings are often highly abrasive, leading to accelerated screen wear. Modern shakers for geothermal use feature robust designs, high-quality screen technology with advanced sealing, and often adjustable motion to handle varying fluid weights and cuttings types, ensuring consistent performance throughout the drill.

Enhancing Drilling Efficiency and Wellbore Integrity

Effective solids control with a reliable shale shaker directly increases the rate of penetration (ROP). A clean drilling fluid allows the bit to cut new rock more efficiently rather than regrinding old cuttings. More importantly, it is vital for wellbore stability. Excessive fine solids in the fluid can lead to thick filter cake, stuck pipe, and poor cementing jobs. By removing a significant portion of solids at the shaker, the load on desanders, desilters, and centrifuges is reduced, leading to a more stable wellbore and higher-quality completion.

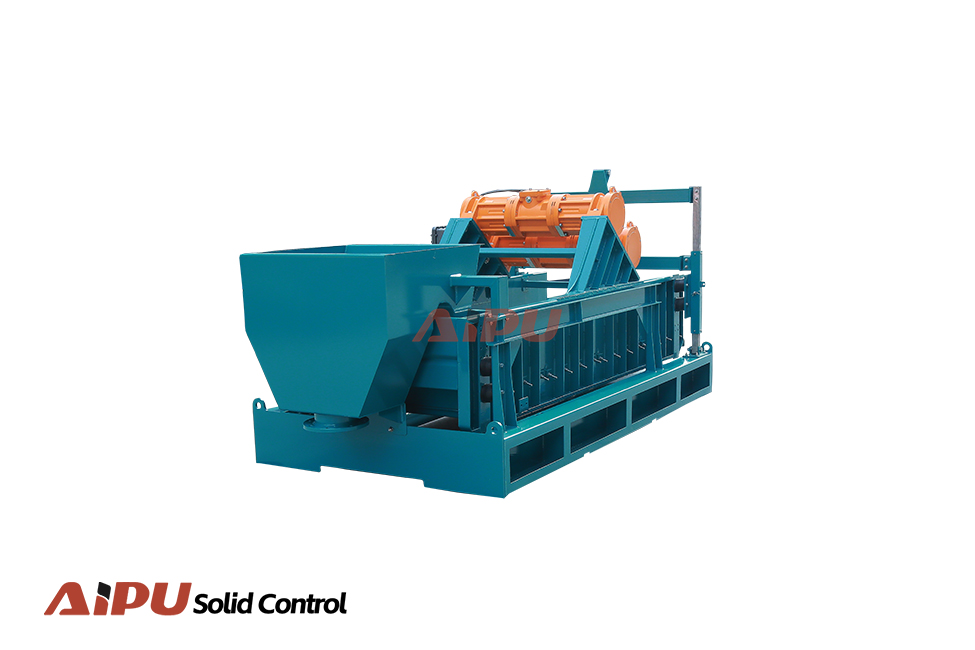

For drilling contractors seeking to optimize their geothermal operations, investing in top-tier solids control equipment is non-negotiable. Aipu stands out as a manufacturer dedicated to providing robust and efficient solids control solutions. Their shale shakers are engineered for demanding applications, offering durability, high screening capacity, and adaptability crucial for the success of modern geothermal drilling projects.