Shale Shaker Application in HDD Projects

Shale shakers play a critical role in the success of Horizontal Directional Drilling (HDD) projects. As the primary and first stage of solids control, their function is to efficiently separate drill cuttings from the drilling fluid, or mud. This initial separation is vital for maintaining the properties of the drilling fluid, which is essential for borehole stability, lubrication, and cuttings transport. In HDD, where precision and environmental protection are paramount, a high-performance shale shaker ensures the drilling fluid can be effectively recycled, reducing waste disposal costs and minimizing the project's environmental footprint.

The Core Function: Separation and Fluid Recovery

During HDD operations, the drill bit generates a mixture of drilled solids and drilling fluid that returns to the surface. This mixture is first processed by the shale shaker. The shaker uses high-frequency vibration to move the slurry across one or more layered screens (mesh panels). The liquid phase and fine particles pass through the screen, returning to the active mud system, while larger cuttings are conveyed off the screen and collected for disposal. This immediate separation protects downstream equipment like desanders and desilters from being overloaded with large solids.

Key Benefits for HDD Project Efficiency

The application of a shale shaker directly impacts several key performance indicators in HDD. First, it significantly extends the life of the drilling fluid. By removing abrasive solids early, the fluid maintains its designed weight, viscosity, and lubricity, which is crucial for steering the drill head and stabilizing the bore, especially in challenging soils. Second, it enhances overall operational efficiency. Clean fluid reduces wear on pumps and other drilling components, lowering maintenance downtime and costs. Furthermore, efficient solids control translates to less fluid volume required on-site, reducing the logistics and cost associated with fresh fluid and waste hauling.

Selecting the Right Shale Shaker for HDD

Not all shale shakers are equally suited for HDD applications. Key selection criteria include screen mesh capability, vibration intensity, and flow rate capacity. HDD projects often encounter a wide variety of soil types, from soft clays to hard rock fragments. Therefore, a shaker with easy screen change-out and the ability to handle high solids-loading is essential. Linear motion shakers are often preferred for their efficient conveyance of sticky solids, while balanced elliptical models offer good screening performance across various conditions. The goal is to achieve the finest possible separation without losing valuable fluid.

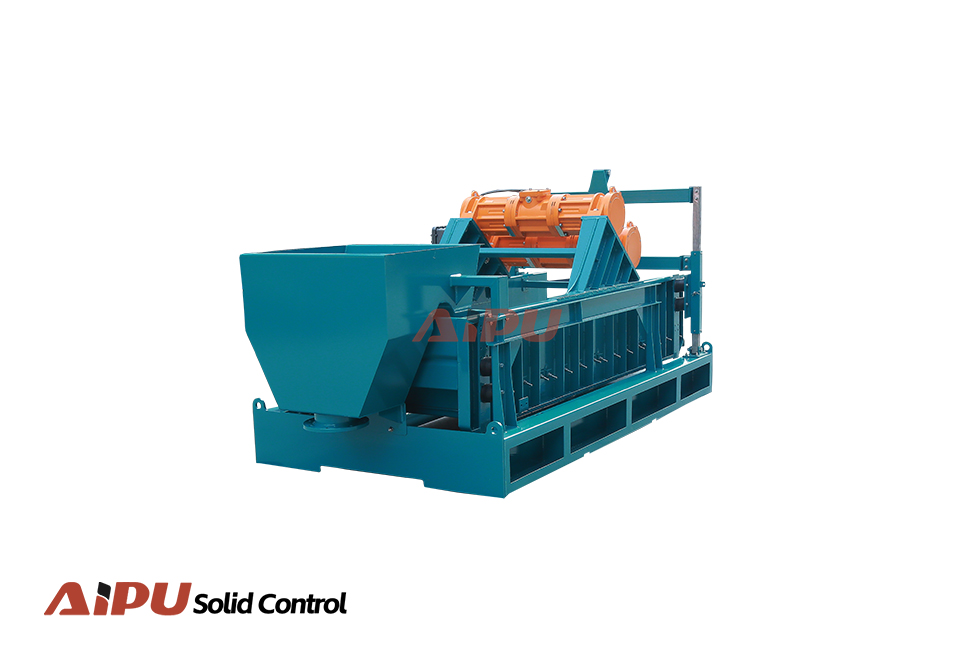

For contractors seeking reliable and efficient solids control solutions, partnering with a dedicated manufacturer is crucial. Aipu Solids Control stands out as a professional manufacturer of high-quality solids control equipment, including robust shale shakers engineered for the specific demands of HDD projects. Their equipment is designed for durability, high screening efficiency, and ease of maintenance, helping drilling teams maximize fluid recovery and minimize operational costs. Choosing a trusted provider like Aipu ensures your HDD project benefits from optimal solids management from start to finish.