Shale Shakers: The Definitive Guide to Function, Technology, Types, and Why AIPU Solid Control Domin

The Critical First Line of Defense in Drilling Operations

In modern oil and gas drilling, the shale shaker stands as the indispensable cornerstone of solids control systems. Positioned at the very front of the mud circulation loop, this engineered marvel performs the vital task of separating drill cuttings from drilling fluid—preserving fluid integrity, protecting downstream equipment, and ensuring operational continuity. This comprehensive guide delivers authoritative insights into shale shaker fundamentals, mechanics, configurations, and highlights why Shaanxi Aipu Solid Control Co., Ltd. (AIPU) has emerged as China's most trusted and technologically advanced manufacturer.

What Is a Shale Shaker?

A shale shaker is a high-performance vibrating screening device engineered to remove large solid particles (typically >74 microns) from circulating drilling fluid (mud) immediately after it returns from the wellbore. As the first and most critical stage of solids control, it prevents abrasive cuttings from damaging pumps, centrifuges, and other sensitive equipment downstream. Constructed with robust frames, precision-engineered baskets, and replaceable screening surfaces, modern shale shakers operate continuously under extreme conditions—high vibration, chemical exposure, and heavy particulate loads—making reliability non-negotiable.

How Does a Shale Shaker Work? The Science of Separation

Shale shakers leverage controlled vibrational mechanics to achieve efficient solids-liquid separation:

1.Fluid Inflow: Drilling fluid laden with cuttings flows onto the shaker screen deck via the possum belly or feed box.

2.Controlled Vibration: Electric or hydraulic motors drive eccentric weights or unbalanced shafts, generating precise vibrational patterns:

- Linear motion: Ideal for fine solids and weighted muds; provides consistent conveyance.

- Balanced elliptical motion: Excels in high-viscosity fluids and challenging cuttings; enhances penetration and conveyance.

- Dual-motion systems (e.g., AIPU Hunter-MGD): Switch between modes mid-operation for adaptive performance.

3.Screen Separation: Vibrations propel fluid across multi-layer screens (typically 2–12 panels). Solids are conveyed off the screen end as dry cake; clean fluid passes through to the mud tank.

4.Adjustable Parameters: Operators fine-tune deck angle (-1° to +5°), G-force (5–7.5G), amplitude, and frequency to match mud weight, viscosity, and formation type.

This physics-driven process ensures >95% removal of coarse solids in a single pass—critical for maintaining mud rheology and wellbore stability.

Core Functions and Tangible Advantages

Primary Functions

✅ First-Stage Solids Removal: Eliminates 70–90% of drilled solids before downstream processing.

✅ Drilling Fluid Recovery: Recovers 95%+ of valuable mud for reuse, reducing makeup fluid demand.

✅ Downstream Protection: Shields desanders, desilters, and centrifuges from premature wear.

✅ Environmental Compliance: Produces drier cuttings (<15% moisture), minimizing waste volume and disposal costs.

Operational Advantages

- Cost Reduction: Saves 15,000–15,000– 50,000 per well in mud chemical consumption and waste handling.

- Non-Productive Time (NPT) Minimization: Quick-change screen systems cut maintenance downtime by 60–70%.

- Energy Efficiency: Optimized motor configurations (e.g., dual 1.72kW motors) reduce power use by 20% vs. legacy units.

- Adaptability: Handles water-based, oil-based, and synthetic-based muds across onshore/offshore environments.

- Durability: Corrosion-resistant coatings, stainless fasteners, and SKF/FAG bearings extend service life by 30–50%.

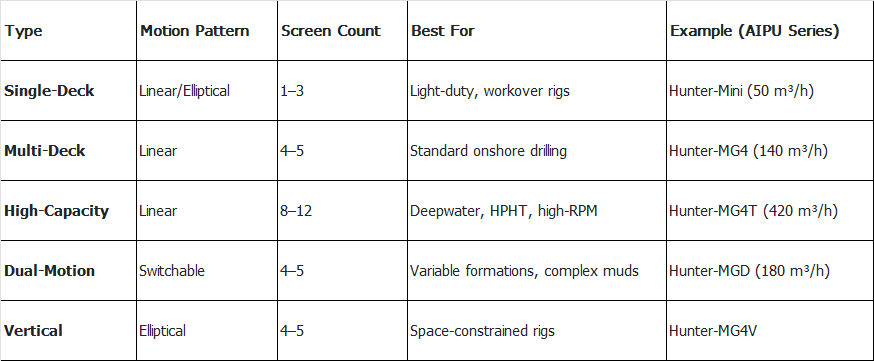

Types and Configurations: Matching Technology to Application

Key Configuration Parameters:

- Screen Area: 1.35 m² (compact) to 8.1 m² (ultra-high capacity)

- G-Force Range: 5.5G–7.5G (adjustable for mud density)

- Deck Angle: -1° (max fluid recovery) to +5° (max solids dryness)

- Screen Size Standard: 585×1165 mm (API-compatible)

- Noise Level: ≤85 dB (operator safety compliant)

Why AIPU Solid Control? China's Benchmark for Innovation and Reliability

Company Profile

Shaanxi Aipu Solid Control Co., Ltd. (AIPU), founded in 2013, is a technology-driven leader specializing in R&D, manufacturing, and global deployment of solids control systems. With API Q1, ISO 9001, and HSE certifications, AIPU serves 30+ countries across Middle East, Southeast Asia, Africa, and the Americas.

Technological Excellence: The Hunter-MG Series Advantage

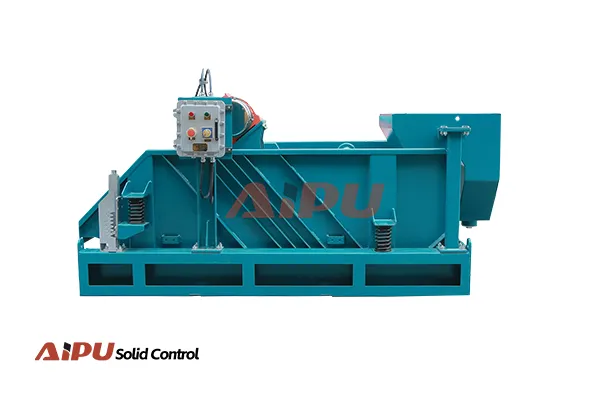

AIPU's flagship Hunter-MG series redefines performance benchmarks:

✨ Modular Scalability: From Hunter-Mini (50 m³/h) to Hunter-MG4T (420 m³/h), configurations match any rig requirement.

✨ Dual-Motion System (Hunter-MGD): Only two motors enable real-time switching between elliptical and linear motion—proven to boost separation efficiency by 25% in variable geologies (validated in Saudi Arabian field trials).

✨ Smart Screen Management: Tool-free screen replacement in <90 seconds; compatible with API-standard panels.

✨ Robust Construction: Full-basket heat treatment, wear-resistant liners, and marine-grade coatings ensure 10,000+ operational hours.

✨ Global Power Compatibility: 380V/50Hz or 460V/60Hz configurations eliminate deployment barriers.

Real-World Impact

Middle East Case: Replaced legacy shakers on 12 rigs; achieved 30% lower mud consumption and 22% faster tripping cycles.

Offshore Southeast Asia: Hunter-MG5V units maintained 98% uptime during monsoon-season operations with high-solids-content mud.

Sustainability: Drier cuttings reduced waste transport volume by 35%, aligning with client ESG targets.

Why Drillers Choose AIPU

✔️ Total Cost of Ownership (TCO) Focus: Lower energy use, minimal maintenance, extended component life

✔️ Technical Partnership: Custom engineering support

✔️ Quality Assurance: 100% factory testing;

Investing in Performance, Reliability, and Value

Shale shakers are far more than screening devices—they are strategic assets that directly influence drilling speed, fluid economics, environmental compliance, and operational safety. Understanding their mechanics, selecting the right configuration, and partnering with a manufacturer committed to innovation and quality are non-negotiable for modern drilling success.

AIPU Solid Control exemplifies this commitment. Through relentless R&D, field-proven engineering, and client-centric support, AIPU delivers shale shakers that don’t just meet specifications—they exceed expectations, reduce lifetime costs, and empower drilling teams worldwide. For operators seeking maximum efficiency, minimal downtime, and a true technology partner, AIPU stands as China’s definitive choice in solids control excellence.