How Do Top Chinese Shale Shakers Enhance Drilling Efficiency and Reduce Operational Costs?

In the oil and gas drilling industry, solids control systems are the core of ensuring efficient and economical operations, and shale shakers, as the first-stage solid-liquid separation equipment in the system, directly determine the subsequent processing efficiency and operational costs. Chinese manufacturing enterprises, represented by Aipu Solids Control Co., Ltd. (Aipu), have broken the monopoly of international brands through technological innovation and precise design, and their shale shaker products have become a benchmark for enhancing drilling efficiency and reducing costs in the global market. This article will deeply analyze how top Chinese shale shakers achieve the dual goals of efficiency improvement and cost reduction, combined with the technical parameters and practical applications of Aipu's products.

Aipu has a team of more than 100 employees and has provided over 300 sets of system solutions to users in more than 30 countries and regions around the world. Its product systems include ZJ90, ZJ80, ZJ70 solids control systems, fracturing fluid treatment systems, waste mud management systems, etc., which are widely used in all links of onshore and offshore oil and gas drilling. The core competitiveness of Aipu lies in its ability to combine cutting-edge technology with practical drilling needs, providing customized, high-efficiency and cost-effective equipment for global customers.

This design allows the shale shaker to adapt to the changes of drilling fluid properties in different strata. For example, in formations with high solid content, the vibration mode can be adjusted to enhance the throwing force of solid particles; in formations with high viscosity of drilling fluid, the vibration frequency can be optimized to avoid screen clogging. The equipment has a maximum treatment capacity of 180m³/h, which is higher than that of traditional shale shakers of the same type. It is especially favored by customers in Europe and the Middle East because of its excellent adaptability.

The market performance of Aipu's products is not only due to their excellent technical performance, but also to the company's comprehensive pre-sales, in-sales and after-sales services. Aipu provides customers with one-stop solutions from system design, equipment customization to on-site installation and debugging, ensuring that the equipment can exert the best performance in actual operation.

With the continuous development of the global oil and gas industry towards intelligence and greening, Chinese shale shaker manufacturers represented by Aipu will continue to promote the technological progress of the industry with the concept of innovation, transcendence and win-win cooperation, and make greater contributions to the efficient and economical development of the global drilling industry.

1. Overview of Top Chinese Shale Shaker Brand: Aipu Solids Control

Founded in 2013, Aipu is a technology-driven manufacturing enterprise dedicated to the R&D, system design, production and sales of drilling mud solids control systems. With 10 years of focused development, the company has built a complete product chain covering drilling fluid shale shakers, mud cleaners, decanter centrifuges, and various auxiliary equipment. It has obtained authoritative certifications such as APIQ1, ISO and HSE, which fully demonstrate its compliance with international standards in environmental protection, safety and quality management.Aipu has a team of more than 100 employees and has provided over 300 sets of system solutions to users in more than 30 countries and regions around the world. Its product systems include ZJ90, ZJ80, ZJ70 solids control systems, fracturing fluid treatment systems, waste mud management systems, etc., which are widely used in all links of onshore and offshore oil and gas drilling. The core competitiveness of Aipu lies in its ability to combine cutting-edge technology with practical drilling needs, providing customized, high-efficiency and cost-effective equipment for global customers.

2. Core Advantages of Aipu Shale Shakers in Enhancing Drilling Efficiency

The efficiency of shale shakers is reflected in the separation effect, treatment capacity and adaptability to complex working conditions. Aipu's HUNTER-MG Series Shale Shaker and Hunter-MGD Dual-Motion Shale Shaker have achieved breakthroughs in these aspects, setting a new standard for the industry.2.1 High-Efficiency Solid-Liquid Separation: Lay a Foundation for Subsequent Processes

As the first-stage separation equipment of the solids control system, the HUNTER-MG Shale Shaker is designed to achieve efficient solid-liquid separation of drilling fluid. Its core advantages include:- Large screen area and high G-force: The maximum screen area of the equipment can reach 2.7m², combined with high G-force design, which can quickly separate solid particles in the drilling fluid. This efficient separation effect avoids the problem of overloading subsequent equipment such as mud cleaners and centrifuges, ensuring the smooth operation of the entire solids control system.

- Flexible deck angle adjustment: The deck angle can be adjusted within the range of -1° to +5°. Operators can flexibly adjust the angle according to the viscosity of the drilling fluid, the size of solid particles and other parameters, ensuring the best separation effect under different drilling conditions.

- Quick-replace screen design: The quick screen replacement structure reduces the downtime for screen replacement from hours to minutes, greatly improving the continuous operation efficiency of the equipment.

2.2 Dual-Motion Vibration Technology: Adapt to Complex Drilling Environments

The Hunter-MGD Dual-Motion Shale Shaker is a representative product of Aipu's technological innovation, adopting internationally advanced dual-motion vibration mode. Different from the traditional single vibration mode, the equipment uses special motors, which can switch between vibration modes at any time during operation, and only 2 motors are needed to realize the dual-motion function.This design allows the shale shaker to adapt to the changes of drilling fluid properties in different strata. For example, in formations with high solid content, the vibration mode can be adjusted to enhance the throwing force of solid particles; in formations with high viscosity of drilling fluid, the vibration frequency can be optimized to avoid screen clogging. The equipment has a maximum treatment capacity of 180m³/h, which is higher than that of traditional shale shakers of the same type. It is especially favored by customers in Europe and the Middle East because of its excellent adaptability.

2.3 High-Quality Material Selection: Ensure Stable Operation of Equipment

The stability of equipment is the key to maintaining continuous drilling operations. Aipu has made strict requirements on the material selection and manufacturing process of shale shakers:- The entire shaker basket undergoes heat treatment, and the surface is coated with wear-resistant and corrosion-resistant coatings, combined with stainless steel fasteners, which can resist the erosion of corrosive media such as hydrogen sulfide in the drilling fluid.

- The use of high-quality raw materials and precision machining processes ensures that the equipment can operate stably for a long time in harsh environments such as high temperature and high pressure, reducing the shutdown rate caused by equipment failure.

3. Cost-Reduction Mechanisms of Aipu Shale Shakers for Drilling Operations

Reducing operational costs is the core demand of oil and gas drilling enterprises. Aipu's shale shakers achieve cost reduction in multiple dimensions such as equipment maintenance, mud loss reduction and subsequent waste treatment.3.1 Reduce Maintenance Costs: Minimize Wear and Tear Parts and Maintenance Time

The design concept of Aipu's shale shakers is "fewer wear parts, easy maintenance", which directly reduces the daily operation and maintenance costs of customers:- Less wear parts: The optimized structural design reduces the number of easily worn components of the equipment. The long service life of the screen and the shaker basket reduces the frequency of parts replacement.

- Low maintenance difficulty: The quick-replace screen design and modular structure allow maintenance personnel to complete maintenance work without professional tools, reducing labor costs and downtime losses. According to customer feedback, the annual maintenance cost of Aipu's shale shakers is 30%-50% lower than that of international brands of the same type.

3.2 Reduce Mud Loss and Waste Disposal Costs

Drilling mud is one of the major cost components in drilling operations, and the loss of mud and the disposal cost of waste solids are important expenses for enterprises. Aipu's shale shakers can effectively reduce these costs:- High separation efficiency: The efficient solid-liquid separation function of the HUNTER-MG Series Shale Shaker can recover more usable drilling fluid, reducing the loss of mud. At the same time, the separated solid phase has lower moisture content, which reduces the subsequent transportation and treatment costs of waste solids.

- Lower overall disposal costs: By reducing the amount of waste solids and improving the recycling rate of mud, the equipment helps drilling enterprises reduce the total cost of waste treatment, which is in line with the environmental protection requirements of the oil and gas industry.

3.3 Customized Configuration: Avoid Unnecessary Investment

Facing the diversified needs of the international market, Aipu provides flexible customized configuration services for shale shakers, helping customers avoid blind investment:- Motor brand options: Customers can choose motors of international brands such as Ital-Vibras, Martin or Oli according to their own needs and regional supply conditions.

- Screen panel customization: Provide steel-framed or composite-framed screen panels to adapt to different drilling fluid properties and solid particle characteristics.

- Structural customization: Support the customization of dual-tandem or triple-tandem structures, as well as the customization of dry shakers and other functional types, to meet the needs of different drilling scales and process requirements.

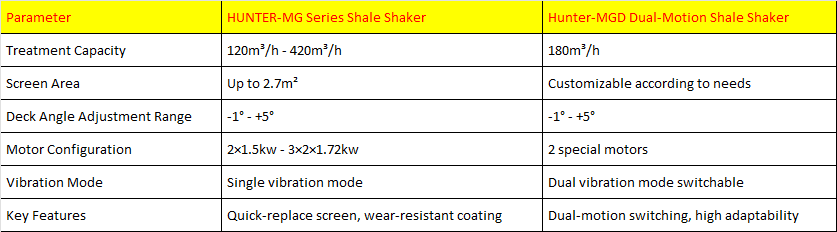

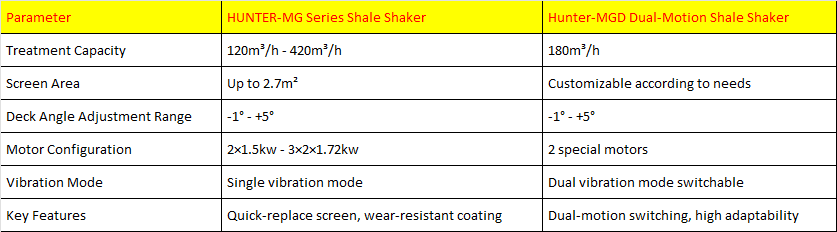

4. Detailed Technical Parameters of Aipu Hunter-Series Shale Shakers

The technical parameters of the equipment are the direct embodiment of its performance. The following table sorts out the core technical parameters of Aipu's HUNTER-MG Series and Hunter-MGD Dual-Motion Shale Shakers, which can help users intuitively understand their advantages:

5. Practical Applications and Market Performance

Aipu's shale shakers have been widely used in onshore and offshore drilling projects around the world, and their performance in improving efficiency and reducing costs has been fully verified. In the Middle East oil fields, Aipu's Hunter-MGD Dual-Motion Shale Shaker has been used in high-temperature and high-salinity drilling environments. By switching vibration modes, it has achieved a separation efficiency of over 95%, reducing the subsequent mud treatment cost by 25% for customers. In the offshore drilling projects in Southeast Asia, the HUNTER-MG Series Shale Shaker, with its large treatment capacity and corrosion-resistant design, has maintained continuous operation for more than 800 hours, reducing the equipment failure rate by 40% compared with similar international products.The market performance of Aipu's products is not only due to their excellent technical performance, but also to the company's comprehensive pre-sales, in-sales and after-sales services. Aipu provides customers with one-stop solutions from system design, equipment customization to on-site installation and debugging, ensuring that the equipment can exert the best performance in actual operation.

6. Conclusion

Top Chinese shale shakers, represented by Aipu's Hunter series, have realized the dual improvement of drilling efficiency and cost reduction through technological innovation, precise design and customized services. Their core competitiveness lies in: taking high-efficiency separation as the core to improve the overall operation efficiency of the solids control system; reducing the operation and maintenance costs and waste disposal costs of enterprises through optimized structural design and material selection; and meeting the diversified needs of global customers through flexible customized configuration.With the continuous development of the global oil and gas industry towards intelligence and greening, Chinese shale shaker manufacturers represented by Aipu will continue to promote the technological progress of the industry with the concept of innovation, transcendence and win-win cooperation, and make greater contributions to the efficient and economical development of the global drilling industry.