Complete Guide to Shale Shaker for Oil Drilling: Everything You Need to Know

The shale shaker for oil drilling represents the most critical first-stage solid control equipment in any drilling fluid recycling system. As the primary solids separation tool on a drilling rig, the shale shaker plays an indispensable role in maintaining drilling efficiency, protecting downstream equipment, and ensuring successful wellbore construction. This comprehensive guide explores every aspect of shale shakers, from their fundamental working principles to advanced maintenance practices, providing drilling engineers and oilfield operators with the knowledge needed to optimize their solids control operations.

The drilling mud cleaning system serves as an obligatory and vital component in modern well drilling equipment. It maintains the normal circulation and stable properties of drilling fluid throughout the drilling process, ensuring the successful completion of drilling operations under the premises of safety, environmental protection, and high efficiency. Within this system, the shale shaker stands as the first line of defense against drill cuttings and other solid contaminants that must be removed from the circulating drilling fluid before it can be reused.

In the oil and gas industry, where drilling operations can cost hundreds of thousands of dollars per day, the efficiency of solid control equipment directly impacts project economics. A well-designed and properly maintained shale shaker can significantly reduce drilling costs, minimize environmental impact, and improve overall drilling performance. Understanding the intricacies of these machines is essential for any professional involved in drilling operations, whether working with land rigs, offshore platforms, or specialized drilling applications.

What is a Shale Shaker and Why It Matters

A shale shaker is a vibrating screen device specifically designed to separate drill cuttings from circulating drilling fluid. The term "shale shaker" originates from the equipment's primary function of handling shale and other formation cuttings generated during the drilling process. These machines use high-frequency vibration to strain mud and silt from the drilling fluid, ensuring that clean drilling mud returns to the active system.

The importance of shale shakers in oil drilling cannot be overstated. As the first-stage solid control equipment in drilling purification systems, shale shakers remove cuttings above 75 micrometers brought from the drilling well. The liquid containing smaller particles then flows into tanks below, where it proceeds to subsequent stages of solid control equipment for further treatment. This initial separation is crucial because it prevents larger abrasive particles from damaging pumps, valves, and other sensitive equipment downstream in the drilling fluid system.

Modern shale shakers are engineered to handle extreme conditions encountered during drilling operations. They must withstand the abrasive nature of drill cuttings, corrosive drilling fluids, and the demanding operational environment of oilfield operations. The design and performance of a shale shaker directly determine the effectiveness of the entire solids control system, making it perhaps the most important piece of equipment in the drilling fluid processing chain.

Working Principle of Shale Shakers

Fundamental Mechanism

The working principle of shale shakers is based on the eccentric force generated by vibrating motors. When drilling fluid returns to the surface from the wellbore, it flows directly to the shale shaker where the separation process begins. The vibrating motor creates eccentric forces that are transmitted through the excitation beam to the screen basket, producing the characteristic vibrating motion that enables solids separation.

As the drilling fluid contaminated with cuttings flows onto the shaker screen, the high-frequency vibration causes larger solid particles to move toward the discharge end of the screen while the drilling fluid and smaller particles pass through the screen mesh. This motion pattern ensures efficient separation while allowing the drilling fluid to be collected for reuse in the drilling process. The vibration intensity, typically measured in G-force, can be adjusted according to the specific drilling conditions and requirements.

Screen Dynamics and Separation Process

The separation efficiency of a shale shaker depends on several interconnected factors including screen mesh size, vibration amplitude, deck angle, and flow rate. The screen mesh size determines the cutoff point for particle separation, with finer meshes capable of removing smaller particles but potentially reducing flow capacity. Most industrial shale shakers offer screen mesh sizes ranging from 40 to 200 mesh, providing flexibility to match specific drilling conditions.

The deck angle, typically adjustable between -1° to +5°, influences both the separation efficiency and the conveyance speed of cuttings across the screen surface. A steeper angle generally increases the conveyance speed, allowing higher throughput but potentially reducing separation efficiency. Operators must balance these factors based on the drilling depth, formation characteristics, and drilling fluid properties to achieve optimal performance.

Modern linear motion shale shakers represent the latest advancement in shaker technology and have become the most common approach to solids control in the oil and gas drilling industry. These shakers produce a linear vibration pattern that efficiently moves cuttings toward the discharge end while providing excellent liquid-solid separation. The linear motion pattern offers superior performance in handling heavy solids loads and provides higher processing capacity compared to older elliptical motion designs.

Types and Classifications of Shale Shakers

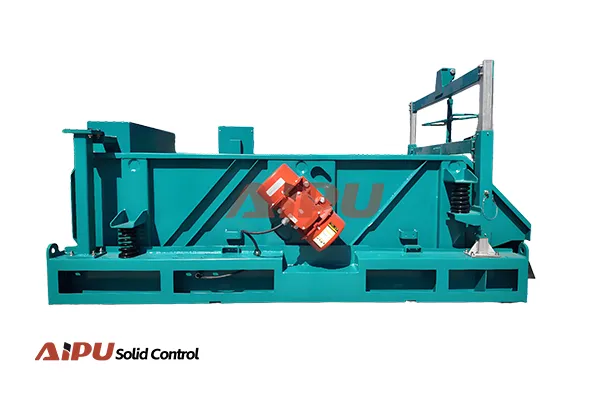

Linear Motion Shale Shakers

Linear motion shale shakers utilize a straight-line vibration pattern that moves cuttings in a single direction across the screen surface. This motion type offers several significant advantages for modern drilling operations. The linear motion provides high-speed conveyance of cuttings, higher processing capacity, and the ability to handle heavier solids loads compared to traditional designs. These shakers typically offer adjustable G-forces up to 7.5G, allowing operators to optimize performance for varying drilling conditions.

The entire shaker deck in quality linear motion shakers undergoes heat treatment to relieve welding stress, enabling it to withstand the high G-forces generated during operation. This construction feature ensures long-term durability and consistent performance even in demanding drilling environments. The shaker screen installation typically employs a mechanical ratchet wrench gear system for quick tightening, facilitating easy disassembly and screen replacement during operation.

Linear motion shale shakers are particularly effective for drilling applications requiring high-volume solids removal, such as extended-reach wells, deep drilling operations, and projects involving hard rock formations. Their efficient cuttings conveyance reduces the risk of screen blinding and extends screen life, resulting in lower operating costs over the life of the equipment.

Balanced Elliptical Motion Shale Shakers

Balanced elliptical motion (BEM) shale shakers produce an elliptical vibration pattern that offers unique advantages for specific drilling applications. This motion type is especially effective during top-hole drilling operations where large volumes of formation cuttings must be handled efficiently. The balanced elliptical orbit provides excellent screening and drainage characteristics, making these shakers ideal for managing high-volume, low-density cuttings loads.

The elliptical motion pattern creates a more gentle screening action compared to linear motion shakers, which can be beneficial when processing fragile or easily degradable cuttings. This characteristic makes BEM shakers particularly suitable for drilling operations where maintaining cuttings integrity is important for formation evaluation purposes. The balanced motion also reduces stress on the shaker structure and screen components, potentially extending equipment life.

Single-Deck, Double-Deck, and Triple-Deck Configurations

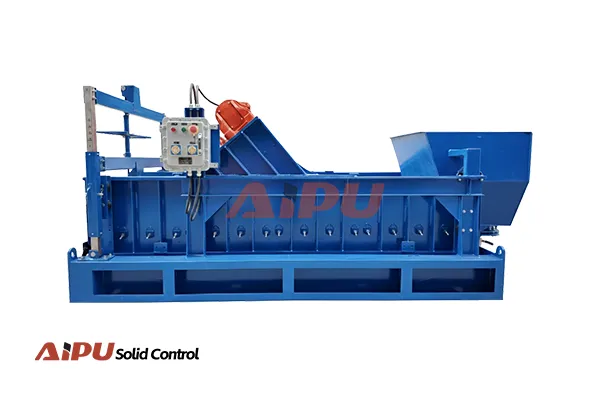

Shale shakers are further classified by the number of screening decks they incorporate. Single-deck shale shakers feature one screen surface and are typically used in applications with moderate solids loading or where space constraints limit equipment size. These units offer simplicity of operation and maintenance, making them suitable for smaller drilling operations or backup applications.

Double-deck shale shakers utilize two stacked screen surfaces, effectively doubling the screening area within the same footprint. This configuration increases processing capacity and improves separation efficiency by allowing finer screening without sacrificing throughput. The upper deck typically removes larger cuttings while the lower deck provides additional fine screening, creating a two-stage separation process within a single unit.

Triple-deck shale shakers represent the highest capacity configuration, incorporating three screen surfaces for maximum solids separation efficiency. These units are designed for demanding drilling operations where maximum solids removal is critical, such as extended drilling campaigns or projects with challenging formation characteristics. The multi-deck design allows for flexible screen configurations to optimize performance for specific drilling conditions.

Key Technical Specifications and Parameters

Vibration Characteristics

Understanding the technical parameters of shale shakers is essential for proper equipment selection and operation. The vibrating strength, typically measured in G-force, determines the intensity of the screening action. Most industrial shale shakers offer adjustable G-forces up to 7.5G or higher, allowing operators to match the vibration intensity to drilling conditions. Higher G-forces provide faster cuttings conveyance and better handling of dense solids but may increase screen wear and power consumption.

The vibration amplitude, typically ranging from 4.14 to 5.96 millimeters, describes the physical displacement of the screen surface during operation. This parameter influences both the separation efficiency and the conveying speed of cuttings across the screen. The amplitude is often linked to the G-force setting and must be properly matched to the screen mesh size and drilling fluid properties for optimal performance.

Screen Specifications and Mesh Selection

The shale shaker screen represents the critical wear component that directly determines separation performance. Screen mesh size is expressed as the number of openings per linear inch of screen, with larger numbers indicating finer mesh and smaller openings. Common mesh sizes range from 40 to 200 mesh, with corresponding aperture sizes from approximately 0.4mm to 0.075mm. The selection of appropriate mesh size depends on the desired cutoff particle size and the drilling fluid properties.

Shale shaker screens are manufactured in various configurations to fit different shaker models and applications. Common screen types include hook strip screens, frame screens, flat screens, and pyramid screens. Each design offers specific advantages in terms of installation ease, screen life, and screening efficiency. The treatment capacity of a single screen can reach 28 liters per second, with screen mesh selection and drilling fluid viscosity affecting actual performance.

Screen construction materials typically include stainless steel wire mesh with various weave patterns to optimize strength, durability, and separation efficiency. The screen frame must provide structural integrity while allowing proper tensioning and sealing to prevent bypass of drilling fluid around the screen edges.

Electrical and Mechanical Specifications

Standard electrical specifications for industrial shale shakers typically include 380V/50Hz or 460V/60Hz configurations, with explosion-proof ratings such as Ex dⅡ BT4 required for hazardous area installations. Motor power varies by design, with common configurations ranging from 2×1.5KW to 2×1.72KW for linear motion units. The electrical control panel provides essential functions including motor speed control, vibration adjustment, and system monitoring.

The deck angle adjustment range, typically from -1° to +5°, allows operators to optimize screening performance for varying drilling conditions. This adjustability is crucial for matching screen performance to changes in drilling rate, formation type, and drilling fluid properties. The adjustment mechanism must provide reliable positioning and maintain the selected angle under the demanding operating conditions of oilfield service.

Applications of Shale Shakers in Oil Drilling

Primary Solids Control Applications

The applications of shale shakers span virtually all drilling operations that utilize liquid drilling fluids. In conventional oil and gas drilling, shale shakers serve as the first line of defense in the five-stage solids control system, removing the largest and most abrasive cuttings before the drilling fluid proceeds to finer separation equipment. This primary separation function protects downstream equipment including centrifugal pumps, hydrocyclones, and centrifuges from excessive wear and damage.

In offshore drilling operations, where space and weight are at premium, the efficiency of shale shaker operation directly impacts the overall rig economics. The high processing capacity and compact design of modern linear motion shakers make them particularly suitable for offshore applications where maximizing solids removal efficiency within limited space constraints is essential. The robust construction required for offshore service ensures reliable operation in the harsh marine environment.

Specialized Drilling Applications

Beyond conventional oil and gas drilling, shale shakers find applications in numerous specialized drilling operations. Coal bed methane (CBM) drilling requires effective solids control to maintain drilling fluid performance in challenging formation conditions. Horizontal directional drilling (HDD) operations depend on shale shakers to manage the large volumes of cuttings generated during guided boring operations, protecting expensive drilling equipment and ensuring project success.

Diamond core drilling operations, where sample integrity is paramount, utilize shale shakers configured to minimize sample degradation while effectively removing cuttings from the drilling fluid loop. Water well drilling and geothermal well drilling applications similarly rely on shale shakers for effective solids management, with the specific requirements varying based on formation characteristics and project objectives.

Selection Guide for Shale Shakers

Factors to Consider

Selecting the appropriate shale shaker for oil drilling requires careful consideration of multiple factors specific to the planned drilling operation. The drilling depth and expected cuttings volume directly influence the required processing capacity, with deeper wells and harder formations typically generating more solids that must be efficiently removed. The physical space available on the drilling rig determines the maximum dimensions and weight constraints for the shaker equipment.

Formation characteristics significantly impact shaker selection decisions. Hard rock formations generate dense, abrasive cuttings that require high G-force shakers with durable screen systems. Soft formations producing larger volumes of sticky cuttings may benefit from elliptical motion shakers with optimized screen configurations for handling difficult-to-screen materials. The drilling fluid type, whether water-based, oil-based, or synthetic-based, also affects material selection and equipment configuration.

Performance Optimization Strategies

Achieving optimal shale shaker performance requires proper setup and ongoing adjustment throughout the drilling operation. Screen selection should be based on the desired cutoff size and expected cuttings characteristics, with finer screens providing better solids removal but potentially reduced capacity. The screen tension must be properly maintained to prevent bypass and ensure uniform flow distribution across the entire screen surface.

Monitoring and adjusting the deck angle based on drilling conditions helps maintain optimal performance as formations change. Higher angles increase cuttings conveyance speed but may reduce separation efficiency, while lower angles provide more thorough screening but risk cuttings buildup on the screen surface. Regular inspection of screen condition and shaker vibration characteristics enables early detection of problems before they impact drilling operations.

Operation and Maintenance Best Practices

Daily Operation Guidelines

Proper shale shaker operation begins with correct startup procedures and continues through ongoing monitoring and adjustment. Before operation, the operator should verify that all screens are properly installed and tensioned, that the deck angle is set appropriately for the current drilling conditions, and that all safety guards and covers are in place. The vibration motors should be started gradually, with the operator observing the initial vibration pattern to ensure proper operation.

During drilling operations, the shaker should be monitored regularly to ensure optimal performance. Signs of problems include abnormal vibration patterns, uneven cuttings distribution across the screen, excessive liquid carryover with the cuttings, and unusual noises from the motor or deck assembly. Prompt attention to these symptoms can prevent more serious problems from developing.

Preventive Maintenance Program

A comprehensive maintenance program for solids control equipment extends equipment life and ensures reliable performance throughout the drilling campaign. Daily maintenance tasks include visual inspection of screens for damage or excessive wear, checking motor temperatures and vibration levels, and verifying proper lubrication of moving components. Weekly tasks should include more detailed inspection of the shaker deck, motors, and drive components.

Regular maintenance procedures should include inspection of the entire machine for evidence of coating damage, including exposed base metal, corrosion, deep scratches, or other voids that could compromise structural integrity. Screen replacement intervals depend on drilling conditions and screen type, with worn screens showing signs of reduced tension, physical damage, or mesh degradation. The shaker deck should be cleaned regularly to prevent cuttings buildup that could affect vibration patterns and screening efficiency.

Troubleshooting Common Issues

Common shale shaker problems and their solutions form an essential knowledge base for drilling operations personnel. Poor separation efficiency often results from incorrect screen mesh selection, worn screens, improper deck angle, or low vibration intensity. These issues can typically be resolved through adjustments to operating parameters or screen replacement.

Excessive screen wear may indicate abrasive drilling conditions requiring more durable screen materials or higher-than-optimal G-force settings. Uneven wear patterns suggest flow distribution problems or screen installation issues that should be addressed to prevent premature failure. Motor overheating can result from electrical problems, bearing failure, or excessive vibration loads that require investigation and correction.

Benefits of Proper Solids Control with Shale Shakers

Economic Benefits

The benefits of effective shale shaker operation extend throughout the drilling operation, starting with protection of expensive downstream equipment. By removing large abrasive cuttings before they enter the main drilling fluid system, shale shakers significantly reduce wear on centrifugal pumps, valves, and other mechanical components. This protection translates directly into reduced maintenance costs and extended equipment life.

Efficient solids removal also reduces drilling fluid consumption by maintaining drilling fluid quality throughout the drilling operation. Clean drilling fluid performs better in terms of hole cleaning, cuttings transport, and formation stabilization, contributing to improved drilling rates and reduced non-productive time. The overall impact on drilling economics can be substantial, with properly functioning solid control equipment potentially saving hundreds of thousands of dollars over the course of a drilling campaign.

Environmental and Safety Benefits

Modern shale shaker technology contributes significantly to environmental protection and operational safety in drilling operations. Effective solids removal reduces the volume of drilling waste that must be disposed of, lowering both disposal costs and environmental impact. The controlled handling of drilling cuttings minimizes the risk of spills and contamination that could harm the surrounding environment.

Safety benefits include reduced risk of accidents related to equipment failure and improved working conditions around the shaker area. Modern shakers incorporate sealed designs and anti-splash features that create cleaner and more comfortable working environments for rig personnel. The reduction in airborne drilling fluid mist and dust through effective screening also improves air quality on the rig floor.

Future Trends in Shale Shaker Technology

The future of shale shaker development focuses on several key areas including improved energy efficiency, enhanced automation capabilities, and advanced materials for extended service life. Variable frequency drives allow precise control of vibration intensity, optimizing performance while minimizing power consumption. Integration with automated solids control systems enables real-time monitoring and adjustment based on drilling conditions.

Advanced materials development continues to improve screen durability and separation efficiency while reducing weight and cost. Composite materials and specialized coatings extend component life in the demanding oilfield environment. These technological advances, combined with improved understanding of drilling fluid mechanics and separation processes, will continue to enhance the performance and value of shale shakers in oil drilling operations.