The Indispensable Role of Shale Shakers in Drilling Fluid Systems: Foundation of Efficient Solids Co

The First Line of Defense in Fluid Integrity

In oil and gas drilling, the drilling fluid system functions as the operational circulatory system—cooling the bit, carrying cuttings, stabilizing the wellbore, and transmitting hydraulic energy. At the very heart of this system lies the shale shaker: the primary solids control device positioned immediately where returning fluid exits the wellbore. It is not merely part of the system—it is the critical gatekeeper determining the entire system’s efficiency, longevity, and economic viability.

System Architecture: Where the Shale Shaker Fits

A typical drilling fluid circulation path:

Wellbore → Flow Line → Possum Belly → Shale Shaker → Mud Tanks (Settling/Agitation) → Desander → Desilter → Centrifuge → Mud Pumps → Back to Bit

- Strategic Positioning: As the first stage of solids control, the shale shaker removes 70–90% of total drilled solids by volume—primarily coarse cuttings (>74 μm / 200 mesh).

- System Cascade Effect: Efficient initial separation prevents downstream equipment overload. If the shaker underperforms, desanders clog, centrifuges foul, and mud pumps suffer accelerated wear.

- Fluid Continuity: Clean fluid returned to mud tanks maintains consistent density, viscosity, and chemical balance—essential for well control and hole cleaning.

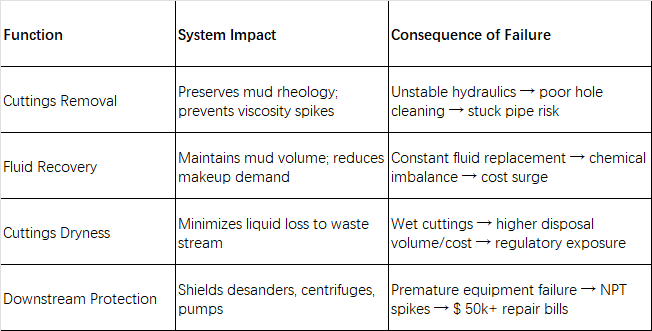

Core System Functions: Beyond Simple Screening

Critical Insight: A 5% drop in shale shaker efficiency can increase total solids control costs by 25% due to cascading effects across the entire fluid system.

Performance Metrics That Define System Health

Fluid Recovery Rate: Target >97%. Every 1% loss in a 200 m³/h system = 2 m³/h of expensive mud wasted.

Cuttings Moisture Content: Target ≤12%. Directly impacts waste handling volume and compliance.

Screen Utilization Efficiency: Optimal pool coverage (⅓ of screen length) ensures full screening area engagement.

G-Force Stability: ±3% fluctuation tolerance maintains consistent separation under variable flow rates.

Integration Synergies: Modern Shale Shakers as System Intelligence Hubs

Today’s advanced shale shakers transcend mechanical separation:

IoT-Enabled Monitoring: Sensors track real-time G-force, screen wear, fluid pool depth, and discharge consistency—data streamed to mud engineers’ dashboards.

Adaptive Motion Control: Systems like AIPU’s patented Hunter-MGD dual-motion technology automatically switch between elliptical motion (for viscous OBM/SBM) and linear motion (for high-flow WBM), optimizing separation without manual intervention.

Mud Logging Integration: Dry, well-separated cuttings enable accurate geological analysis at the shaker discharge point—critical for geosteering decisions.

Closed-Loop System Compatibility: Ultra-dry discharge (<10% moisture) supports zero-liquid-discharge (ZLD) initiatives and environmental stewardship.

Selecting a Shale Shaker for System-Wide Harmony

Choosing the right shaker requires holistic system thinking:

Flow Rate Matching: Shaker capacity must exceed maximum circulation rate (e.g., 420 m³/h Hunter-MG4T for deepwater rigs).

Mud System Compatibility: OBM/SBM demands high dryness; WBM in reactive shales requires gentle motion to avoid screen blinding.

Footprint & Layout: Must integrate seamlessly with mud tank geometry and access pathways.

Serviceability: Quick-screen-change systems minimize downtime during critical operations.

Manufacturers like AIPU Solid Control engineer shale shakers as integrated system components, not standalone units. Their Hunter-MG series features modular decks, corrosion-resistant frames, and API-certified construction—designed from inception to harmonize with global drilling fluid system standards. Field deployments across Permian Basin, Middle East carbonate fields, and offshore Gulf of Mexico consistently validate: when the shale shaker performs optimally, the entire fluid system operates with precision, economy, and resilience.

The System Multiplier

The shale shaker is far more than “the machine with screens.” It is the foundational multiplier of drilling fluid system performance. Its efficiency dictates mud quality, equipment lifespan, operational cost, environmental footprint, and ultimately, drilling success. Investing in a high-integrity, intelligently designed shale shaker—backed by engineering partnership and global support—is not a line-item expense. It is a strategic commitment to system-wide excellence.

For drilling teams committed to fluid system integrity and operational excellence, partnering with innovators like AIPU Solid Control ensures your first line of defense is engineered for reliability, adaptability, and measurable value—well after well.