Brief Solids Control Drilling Fluid

Solids are removed for better mud control. There are three basic ways of conditioning drilling fluids, all relating to solids:

- adding solids or their equivalent.

- removing solids.

- treating solids (chemically).

Why Solids Control Process Are So Imporant

Removing solids is necessary before a drilling fluid is pumped to the drill bit. The more effective the mechanical solids control, the less dilution and chemical treatment are required. The addition of water does not necessarily dilute a drilling mud in a drilling situation.

In some situations, the dynamic fluid loss can be very high. Failure to replace the filtrate loss would cause a decrease in liquid volume and resultant increase in per cent solids, weight, and viscosity, independent of the drilling rate. If the filtration loss is constantly replaced however, the properties of a mud are continuously restored. Whether this "pass-through water" amounts to most or a minor part of the total water requirement, depends upon the ratio of the dynamic down-hole filtration rate to the solids removal rate. The total amount of solids can be altered only by the addition and removal of drilled and commercial solids regardless of the amount of water being added.

Plastic viscosity is not a function of total solids content by volume, unless it is maintained at an absolute minimum. If a drilling flui does not contain commercial suspended solids it is unweighted and if it does contain them is weighted. The total solids content in weighted muds usually will be high.

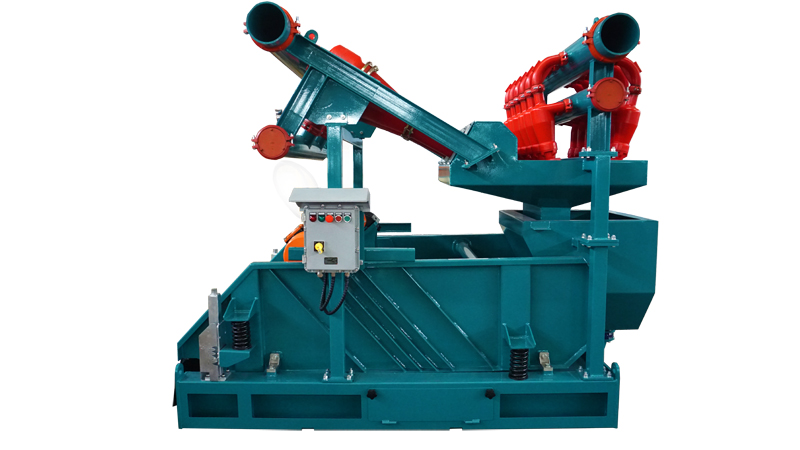

The primary solids control equipment are shale shaker, sand trap, hydrocyclone desander, hydrocyclone desilter and decanting centrifuge.

Shale Shaker In Solids Control

The term "shale shaker" is used in drilling mud work to cover all the equipment like shaking screen, vibrating screen, and osillating screen. Vibrating screen devices are most used. The volume of liquid discharge that can pass through a vibrating screen depends upon per cent open area, mesh opening size, type of motion, mud flow properties, solids content of liquid discharge, feed rate of oversize solids, and type of oversized solids. The volumetric rate of solids discharge that can be handled depends on type of screen motion, speed and amplitude, horsepower, type of solids, mesh design, and wire strenght. The size range of solids that can be separated is determined by mesh opening size, type of screen motion, speed and amplitude, and screen mesh weave.

Type of motion is determined both by eccentric weight or reciprocator arrangement and by the suspension system. If either of them is not in good condition, the shale shaker cannot perform properly.

Sand Trap Biref

The major operating principles of sand traps are as follows:

- The sand trap, which usually reeives the liquid slurry passing through the shale shaker, should receive all liquid slurry bypassing the shale shaker and flowing into the active mud traps.

- A sand trap is a gravity-settling compartment, it must bot be stirred and/or be used as a sunction compartment for any solids control process.

- A sand trap must have a discharge control assembly, which can be easily and quickly opened and closed, so that the settled solids can be dumped with a minimum loss of mud.

- The sand trap shoiuld be only dumped and not "washed out". If bottom is not sloped to the solids pile angle, the settled solids should be allowed to form their own sloped sides, "cleaning the bottom", other than possibly at moving time, only increases mud loss and mud cost.

- Large quantities of barite may be settled from weighted drilling fluids. Provisions for by-passing the undersize screen discharge slurry from the carrying pan directly to the next processing compartment is advisable when using weighted muds. All compartments except the sand trap are stirred in a well-designed active system to prevent settling out of barite. The sand trap must not be by-passed if there is any problem with the shale shaker.

- The mud exit from the sand trap should be over a retaining weir to a stirred compartment.

Main Function Of Degasser

Degasser sometimes are essential to the solids control process, even through shale shakers remove a good portion of the gas from a badly gas-cut mud, especially if the yield point is as low as 10lb/100ft2. Slurry-handling centrifugal pumps feeding abrasive oil-field muds to hydrocyclones loss efficiency when pumpimg gas-cut muds. They will "gas lock" when gas content exceeds 3 per cent by volume. Hydrocyclones do not function properly if pumping head is not connstant or if there is gas or air in the feed. Provision for degassing equipment, therefor, should be made between the sand trap and the first hydrocyclones. Hydrocyclone can acoomplish the finest separation of any primary separation equipment normally used on the full-flow circulating rate of an unweighted mud system.