Drilling fluid shale shaker with different screen panels

Drilling fluid shale shaker is the most used solid control equipment in the process of oil drilling mud treatment. Shaker screens as the vital important spares for removing solid and recovering drilling fluid, it has an important effect for the working performance. Therefore, how to select a suitable panels for your usage?

To meet the different requirements, AIPU designed the shale shaker with composite frame screen panels, SS sealing screens, and steel frame shaker screen.

Composite framed screen shale shaker

Composite framed shaker screen is common used in oil and gas well drilling, the screen panel with non-metal frame. The internal steel frame is covered by composite materials. Consisting plastic, fibers, carbons and so on. Dimension is 585x1165mm. It is API RP 13 complaint. Both AIPU shaker Hunter-MG4 and Hunter-MG3 are configurated with this type. Besides, AIPU composite framed screen can be interchangeable with the famous brand.

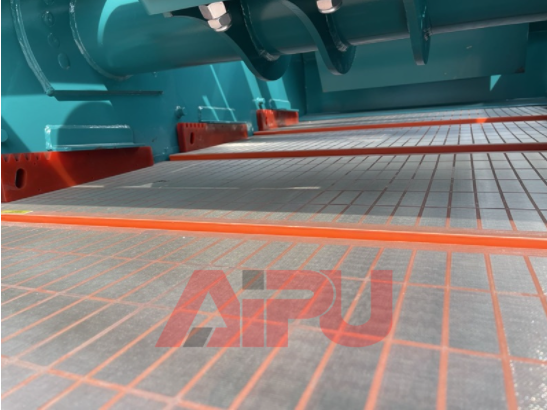

Shale shaker with steel frame panels

The steel frame shaker screen is created of high-strength square steel tubing welded into a multi-ribbed slab construction that is both strong and long-lasting. The screen mesh is separated into several tiny independent meshes to minimize local damage and excessive growth.Meanwhile, special rubber is available to fix the damage, saving time and money. This screen is used in shale shakers with wedge fastening equipment. The clients from horizontal directional drilling more prefer to this type of shale shaker.

Stainless steel sealing screens shaker

Some customers from environment company to process the oil sludge, we designed the stainless steel sealing screens for shale shaker. And just offer us the particle size mm you want to separate, we can customized the different screens panels for you. Compared with composite framed screen, the SS sealing screen has a better working performance in oil sludge separation