Solids Control Equipment and Oil and Water Tanks Were Shipped To Client

The AIPU team has just delivered a ZJ40 solid control system to Oman. The system can achieve a mud processing capacity of 240m ³/h. With the cooperation of solid control equipment such as vibrating screens, vacuum degassing devices, desander, desilter, centrifuge, and jet mixing devices, the ZJ40 drilling rig meets the requirements for mud purification, proportioning, circulation, and supply.

Omanas an important oil producing country in the Middle East, has always had a strong demand for advanced energy equipment. The cooperation and successful delivery of ZJ40 system between AIPU company and Oman customer is based on the high recognition of each other's professional capabilities and product quality. AIPU company has won the trust of Omani customers with its good reputation in the industry, high-quality products, and comprehensive service guarantee system. The foldable walkway, guardrail, etc. in the ZJ40 mud solid control system customized for Middle Eastern customers have a compact design structure that is easy to install and disassemble.

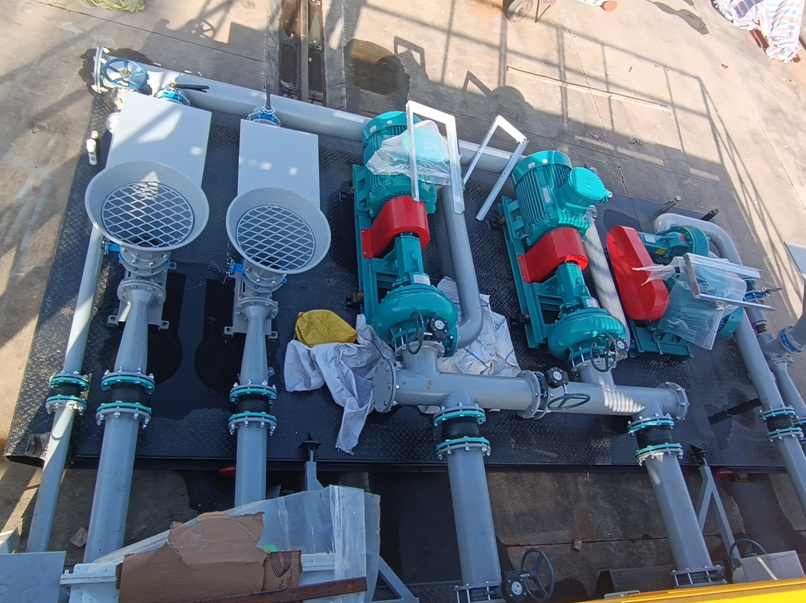

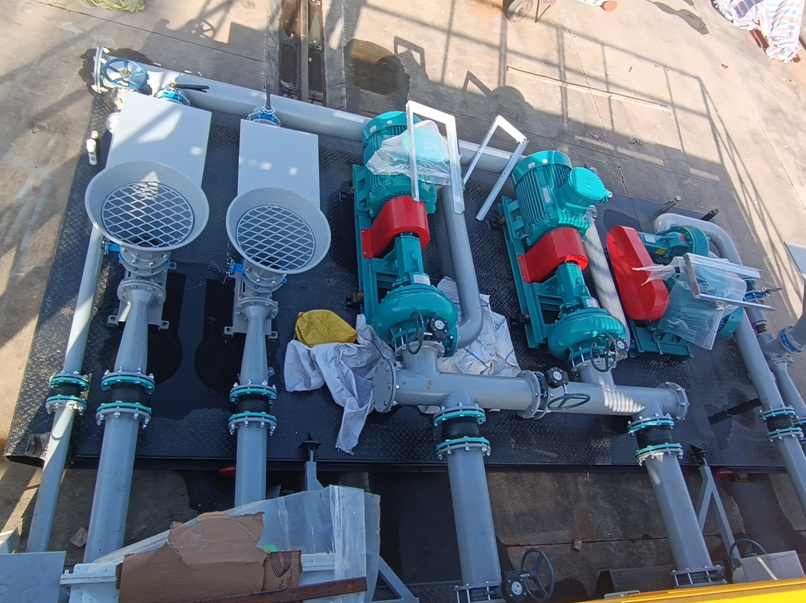

The solids control system consists of four levels of purification equipment such as three mud tanks, shale shakers, degassers, desanders and desilters (integrated machine), centrifuges, as well as mud agitators, sand pumps, weighting pumps, shear pumps, mixing and weighting devices, etc. The system process is as follows: After the drilling fluid returns from the wellhead, it passes through the elevated aqueduct to the shale shaker for the first stage of solid-liquid separation. After degassing, it is pumped by the sand pump on Tank No. 1 into the integrated machine for the second stage of solid-liquid separation. The separated drilling fluid then enters the desilting bin for the third stage of solid-liquid separation. After that, the separated drilling fluid enters Tank No. 2 and is subjected to the fourth stage of solid-liquid separation by the centrifuge. Then it enters Tank No. 3 and is pumped back into the well by the drilling pump for reuse.

The effective volume of the grouting metering tank is more than 10 cubic meters. It is located between the wellhead and Tank No. 1. Two 11KW grouting pumps are installed at the end of the grouting tank. During the process of pulling out the drill pipe, the grouting pump can be used to pour mud into the wellhead. When the grouting tank needs to be replenished with mud, the weighting pump can be used to transport the mud, which has been purified, to the grouting tank through the low-pressure mud pipeline.

Omanas an important oil producing country in the Middle East, has always had a strong demand for advanced energy equipment. The cooperation and successful delivery of ZJ40 system between AIPU company and Oman customer is based on the high recognition of each other's professional capabilities and product quality. AIPU company has won the trust of Omani customers with its good reputation in the industry, high-quality products, and comprehensive service guarantee system. The foldable walkway, guardrail, etc. in the ZJ40 mud solid control system customized for Middle Eastern customers have a compact design structure that is easy to install and disassemble.

The solids control system consists of four levels of purification equipment such as three mud tanks, shale shakers, degassers, desanders and desilters (integrated machine), centrifuges, as well as mud agitators, sand pumps, weighting pumps, shear pumps, mixing and weighting devices, etc. The system process is as follows: After the drilling fluid returns from the wellhead, it passes through the elevated aqueduct to the shale shaker for the first stage of solid-liquid separation. After degassing, it is pumped by the sand pump on Tank No. 1 into the integrated machine for the second stage of solid-liquid separation. The separated drilling fluid then enters the desilting bin for the third stage of solid-liquid separation. After that, the separated drilling fluid enters Tank No. 2 and is subjected to the fourth stage of solid-liquid separation by the centrifuge. Then it enters Tank No. 3 and is pumped back into the well by the drilling pump for reuse.

The effective volume of the grouting metering tank is more than 10 cubic meters. It is located between the wellhead and Tank No. 1. Two 11KW grouting pumps are installed at the end of the grouting tank. During the process of pulling out the drill pipe, the grouting pump can be used to pour mud into the wellhead. When the grouting tank needs to be replenished with mud, the weighting pump can be used to transport the mud, which has been purified, to the grouting tank through the low-pressure mud pipeline.