Key to Eco - friendly and Efficient Drilling

In the realm of drilling operations, the solids control system stands as an unsung hero, playing a crucial yet often overlooked role in ensuring the success of drilling projects. This system is designed to remove unwanted solids from the drilling fluid, maintaining its quality and performance.

The Functionality of Solids Control System

The primary function of a solids control system is to separate the cuttings and other solid particles from the drilling mud. As the drill bit penetrates the earth, it generates a large amount of cuttings that need to be removed from the mud. If these solids are not properly removed, they can cause a variety of problems, such as increased wear on drilling equipment, reduced drilling efficiency, and even wellbore instability. The solids control system uses a series of equipment, including shale shakers, desanders, desilters, and centrifuges, to achieve the separation of solids from the drilling fluid.

The Importance of Solids Control in Drilling

Solids control is of utmost importance in drilling operations. Firstly, it helps to extend the life of drilling equipment. By removing the abrasive solids from the drilling fluid, the wear and tear on the drill bit, pumps, and other components are significantly reduced. This not only saves on equipment replacement costs but also minimizes downtime for maintenance. Secondly, proper solids control improves drilling efficiency. Clean drilling fluid allows for better lubrication and cooling of the drill bit, enabling faster penetration rates. Additionally, it helps to maintain the stability of the wellbore by preventing the accumulation of solids that could cause blockages or collapse.

Components of a Solids Control System

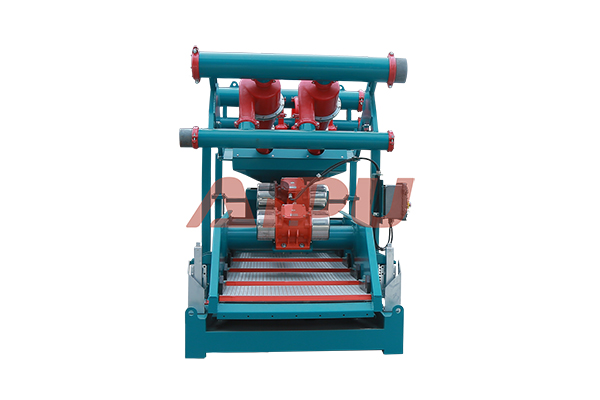

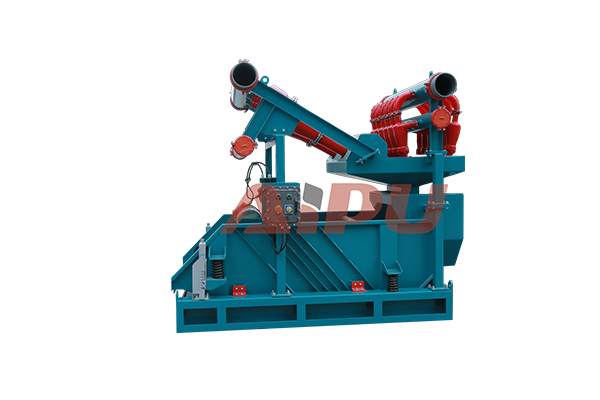

A typical solids control system consists of several key components. The shale shaker is the first stage of solids removal. It uses vibrating screens to separate the larger cuttings from the drilling fluid. The desander and desilter are used to remove smaller particles. They work based on the principle of hydrocyclones, which use centrifugal force to separate the solids from the fluid. The centrifuge is the final stage of solids control, capable of removing the finest particles from the drilling fluid. Each component plays a vital role in the overall performance of the solids control system.

Advancements in Solids Control Technology

Over the years, there have been significant advancements in solids control technology. Newer equipment designs are more efficient, reliable, and environmentally friendly. For example, some shale shakers now use advanced screen technologies to improve the separation efficiency. Centrifuges have also become more powerful and precise, allowing for better control of the solids removal process. Moreover, there is a growing trend towards the development of closed-loop solids control systems, which minimize the environmental impact by reducing waste discharge. These advancements are continuously enhancing the effectiveness of solids control systems in drilling operations.

In conclusion, the solids control system is indeed the unsung hero of drilling success. Its proper functioning is essential for the smooth and efficient operation of drilling projects, from protecting equipment to ensuring wellbore stability. As technology continues to evolve, the role of the solids control system will only become more critical in the future of drilling.

The Functionality of Solids Control System

The primary function of a solids control system is to separate the cuttings and other solid particles from the drilling mud. As the drill bit penetrates the earth, it generates a large amount of cuttings that need to be removed from the mud. If these solids are not properly removed, they can cause a variety of problems, such as increased wear on drilling equipment, reduced drilling efficiency, and even wellbore instability. The solids control system uses a series of equipment, including shale shakers, desanders, desilters, and centrifuges, to achieve the separation of solids from the drilling fluid.

The Importance of Solids Control in Drilling

Solids control is of utmost importance in drilling operations. Firstly, it helps to extend the life of drilling equipment. By removing the abrasive solids from the drilling fluid, the wear and tear on the drill bit, pumps, and other components are significantly reduced. This not only saves on equipment replacement costs but also minimizes downtime for maintenance. Secondly, proper solids control improves drilling efficiency. Clean drilling fluid allows for better lubrication and cooling of the drill bit, enabling faster penetration rates. Additionally, it helps to maintain the stability of the wellbore by preventing the accumulation of solids that could cause blockages or collapse.

Components of a Solids Control System

A typical solids control system consists of several key components. The shale shaker is the first stage of solids removal. It uses vibrating screens to separate the larger cuttings from the drilling fluid. The desander and desilter are used to remove smaller particles. They work based on the principle of hydrocyclones, which use centrifugal force to separate the solids from the fluid. The centrifuge is the final stage of solids control, capable of removing the finest particles from the drilling fluid. Each component plays a vital role in the overall performance of the solids control system.

Advancements in Solids Control Technology

Over the years, there have been significant advancements in solids control technology. Newer equipment designs are more efficient, reliable, and environmentally friendly. For example, some shale shakers now use advanced screen technologies to improve the separation efficiency. Centrifuges have also become more powerful and precise, allowing for better control of the solids removal process. Moreover, there is a growing trend towards the development of closed-loop solids control systems, which minimize the environmental impact by reducing waste discharge. These advancements are continuously enhancing the effectiveness of solids control systems in drilling operations.

In conclusion, the solids control system is indeed the unsung hero of drilling success. Its proper functioning is essential for the smooth and efficient operation of drilling projects, from protecting equipment to ensuring wellbore stability. As technology continues to evolve, the role of the solids control system will only become more critical in the future of drilling.