Why Proper Screen Selection Matters for Mud Cleaner

In the high-stakes environment of offshore drilling, operational efficiency and environmental protection are non-negotiable. The complex process of drilling a well relies heavily on a closed-loop system where drilling fluid, or mud, is continuously circulated. This fluid performs critical functions, from cooling the drill bit and stabilizing the wellbore to carrying rock cuttings to the surface. However, once the fluid returns, it is contaminated with a mixture of solids of varying sizes. If these solids are not efficiently removed, they can cause a cascade of problems, including increased abrasive wear on equipment, reduced drilling rates, and compromised wellbore stability. This is where the role of a specialized solids control unit becomes paramount. The effective separation of drilled solids from the drilling fluid is not merely a matter of maintenance; it is a fundamental requirement for safe, cost-effective, and successful drilling operations in the challenging offshore realm.

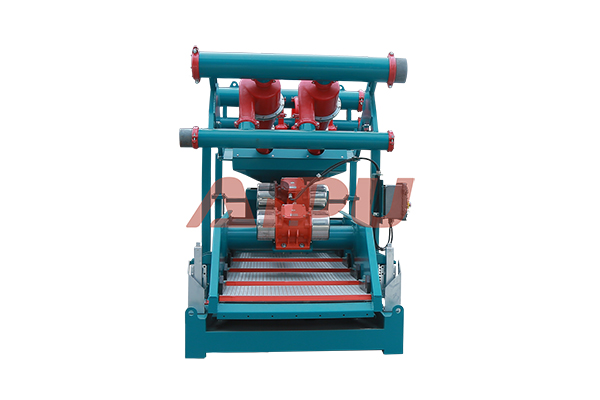

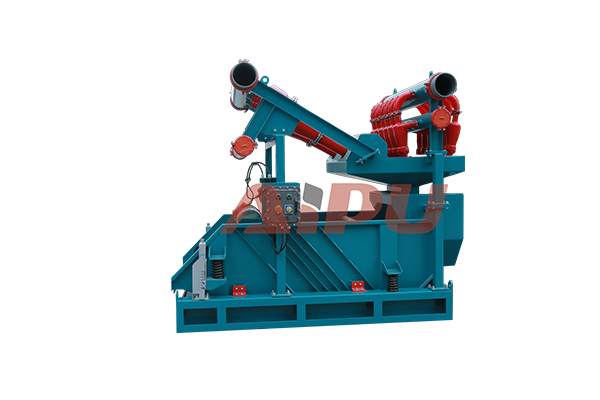

The Composition and Function of a Mud Cleaner

A mud cleaner is an integral component of the solids control hierarchy on a drilling rig. It is essentially a combination unit that integrates a desilter and a fine-mesh vibrating screen. The process begins with the hydrocyclones of the desilter section. These cones use centrifugal force to separate heavy solids and fine silt from the drilling fluid based on particle size and density. The cleaned fluid exits from the top of the cones, while the discarded solids and a portion of the liquid are discharged from the bottom. This underflow, which still contains valuable liquid, is then directed onto a high-frequency vibrating screen. The screen captures the remaining fine solids, allowing the liquid to pass through and be returned to the active mud system. This two-stage process makes the mud cleaner exceptionally effective at removing particles in the 15 to 50 micron range, a size fraction that is often too fine for shale shakers alone but too coarse for centrifuges to handle economically in the primary stages.

Why It's Critical for Offshore Drilling Operations

The criticality of a mud cleaner in offshore drilling is amplified by the unique challenges of the marine environment. First and foremost is the issue of limited space and weight capacity on offshore platforms and rigs. Every piece of equipment must justify its footprint. A mud cleaner, by performing the dual function of a desilter and a dewatering screen, saves valuable space while delivering superior performance. Furthermore, the cost of drilling fluids is exponentially higher offshore. Barite, a weighting material, is expensive, and losing it through inefficient solids control directly impacts the bottom line. By efficiently recovering barite and other valuable liquid, the mud cleaner significantly reduces the need for fresh fluid and chemical additives, leading to substantial cost savings.

Operational safety and efficiency are also heavily dependent on proper solids control. An accumulation of fine solids increases the mud's viscosity and density, which can lead to a higher equivalent circulating density (ECD). An excessively high ECD can fracture the formation, resulting in lost circulation, well control issues, and potentially a catastrophic blowout. By maintaining the mud properties within the desired specifications, the mud cleaner helps mitigate these risks. It also protects downstream equipment, such as pumps and drill bits, from excessive abrasive wear, thereby reducing non-productive time and maintenance costs.

Economic and Environmental Advantages

The economic argument for deploying a high-performance mud cleaner is compelling. The direct savings from reduced drilling fluid consumption and disposal costs are significant. Offshore waste disposal is a complex and expensive process, governed by stringent environmental regulations. By minimizing the volume of waste generated through efficient solids removal, operators can drastically cut their disposal costs and simplify their waste management logistics. This also translates into a smaller environmental footprint, as less waste is discharged or shipped to shore for processing. The ability to reuse drilling fluid not only conserves resources but also aligns with the industry's growing focus on sustainable and environmentally responsible operations.

Integration into the Solids Control System

For optimal performance, the mud cleaner must be correctly positioned within the broader solids control system. Typically, it follows the shale shakers and degasser but precedes the centrifuge. The shale shakers remove the larger cuttings, while the mud cleaner targets the fine sands and silts. This staged approach ensures that each piece of equipment operates within its most efficient range, preventing overloading and maximizing the overall system's effectiveness. Proper integration ensures that the drilling fluid reaching the centrifuge is already largely free of coarse and intermediate solids, allowing the centrifuge to focus on separating the ultra-fine colloids and recovering the highest-value weighting materials.

The relentless pursuit of efficiency and safety in offshore drilling makes advanced equipment like the mud cleaner indispensable. Its role in preserving drilling fluid properties, protecting expensive equipment, and reducing operational costs solidifies its status as a critical asset on any modern offshore rig. When considering the procurement of such vital equipment, it is prudent to partner with a reputable manufacturer known for reliability and performance. Aipu Solid Control has established itself as a leading provider of high-quality solids control equipment, including robust and efficient mud cleaners designed for the demanding conditions of offshore operations. For drilling contractors seeking to optimize their process, Aipu represents a trusted partner for their equipment needs.