Shale Shaker vs Desander Key Differences Explained

In the complex world of drilling fluid management, two pieces of equipment stand as critical first lines of defense: the shale shaker and the desander. For those new to the oil and gas industry, or even seasoned professionals looking for a refresher, the distinction between these two machines can sometimes be blurred. Both are integral components of the solids control system, a setup designed to remove drilled solids from the drilling fluid, or mud. This mud is essential for lubricating the drill bit, maintaining wellbore pressure, and carrying cuttings to the surface. If these solids are not efficiently removed, they can lead to a cascade of operational issues, including increased drilling costs, equipment wear, and potential wellbore instability. While their ultimate goal is aligned, the shale shaker and desander operate on fundamentally different principles and target different particle sizes. Understanding their unique roles, capabilities, and placement within the processing sequence is not just academic; it is crucial for optimizing drilling efficiency, ensuring safety, and controlling costs on any modern drilling rig.

The Primary Function and Operating Principle

The most fundamental difference lies in their method of separation. A shale shaker is a screening device. It utilizes a vibrating screen with specific mesh sizes to separate solids from liquid based purely on particle size. The unprocessed drilling fluid, laden with cuttings of various sizes, flows onto the vibrating screen deck. The liquid phase and particles smaller than the screen mesh pass through, while larger solids are conveyed off the end of the screen and discarded. It is a straightforward mechanical filtration process. In contrast, a desander is a centrifugal separation device. It uses a hydrocyclone, a cone-shaped unit with no moving parts, to create a vortex. As the fluid mixture is pumped tangentially into the hydrocyclone, rapid rotation generates strong centrifugal forces. These forces throw the heavier, coarser solids outward and downward to be discharged from the apex (bottom) of the cone, while the cleaned fluid and finer particles exit upward through the vortex finder at the top.

Particle Size Removal and Efficiency

This difference in operating principle directly dictates the size of particles each unit is designed to remove. The shale shaker is the first and most coarse removal step in the solids control hierarchy. Its primary job is to remove the large, bulk solids—typically those greater than 74 microns (200 mesh) in size, though finer screens can be used for more demanding applications. It is the workhorse that handles the initial high volume of cuttings. The desander, positioned later in the process, is a finer cleaner. It is specifically engineered to remove solids in the range of 45 to 74 microns. It takes the underflow from the shaker and the desilter (a finer hydrocyclone) and removes the medium-sized, abrasive sand particles that the shaker cannot capture. Using a desander is essential for protecting downstream equipment from the abrasive wear caused by these sand-sized particles.

Placement in the Solids Control System

The sequence of equipment is not arbitrary; it is a carefully engineered process flow designed for maximum efficiency. The drilling fluid returning from the wellbore always goes to the shale shakers first. As the primary and most vital solids control device, the shaker must process 100% of the mud flow to remove the largest cuttings. The fluid that passes through the shaker screens, now largely free of large solids, then collects in a common tank, often called the mud tank. From this tank, the fluid is pumped to the next stage of processing: the desander. The desander does not process the entire mud stream directly from the flow line; it only processes a portion of the fluid that has already been pre-cleaned by the shaker. After the desander removes the sand-sized particles, the fluid may then proceed to a desilter (for even finer particles) and a degasser (for removing entrained gases) before being recirculated back into the well.

Key Design and Operational Characteristics

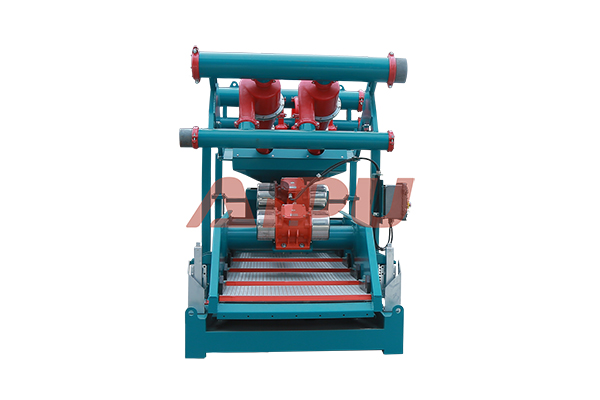

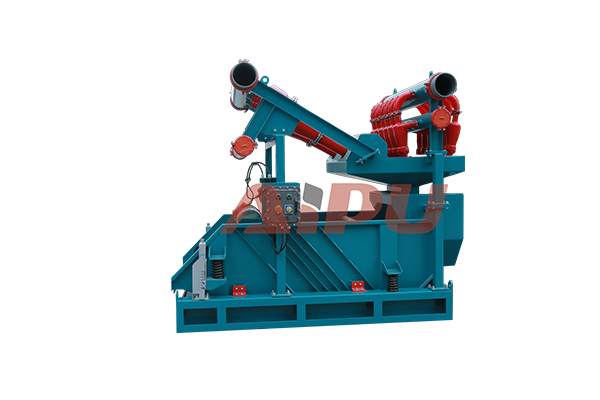

Visually and mechanically, the two pieces of equipment are distinct. A shale shaker is characterized by its vibrating screen deck(s), which can be linear or elliptical in motion, and its electric or hydraulic motors that provide the vibration. The key variable for a shaker is the screen mesh size, which determines the cut point. Desanders, on the other hand, are recognized by their banks of hydrocyclones, usually mounted above a dedicated tank. They require a dedicated pump to feed them with sufficient pressure and flow to create the necessary vortex within each cone. The primary operational variable for a desander is the size of the hydrocyclone's inner diameter; a 10-inch cone is standard for a desander, while smaller cones are used for desilters.

In practice, the choice between using a shale shaker and a desander is not a choice at all—a properly configured system requires both. They are complementary, not interchangeable, technologies. The shaker acts as the coarse filter, protecting the desander from being overwhelmed by large solids that could plug its cones. The desander, in turn, acts as a fine filter, capturing the abrasive particles that prematurely wear out pumps, drill bits, and other downstream equipment. Neglecting either one can have significant consequences. Bypassing the shaker would quickly plug and destroy the desander, while operating without a desander leads to accelerated equipment wear and poor drilling fluid properties. For drillers and mud engineers, a deep understanding of this symbiotic relationship is key to maintaining a clean, stable, and efficient drilling fluid system, ultimately contributing to a safer and more cost-effective drilling operation.