Choosing the Right Shale Shaker for Your Drilling Rig

In the complex and costly world of drilling operations, efficiency and reliability are paramount. The first line of defense in your solids control system is the shale shaker. Its primary job is simple yet critical: to remove large drilled solids from the drilling fluid (mud) before it passes through the rest of the cleaning system. Choosing the wrong shaker can lead to a domino effect of problems—premature wear on downstream equipment, increased chemical costs, poor hole cleaning, and even wellbore instability. Therefore, selecting the right shale shaker is not just an equipment decision; it's a fundamental financial and operational strategy.

Key Factors in Selecting a Shale Shaker

When evaluating shale shakers for your rig, consider these critical factors:

Screen Panel Technology: The heart of any shaker is its screen. Look for shakers that can handle high-performance, fine-mesh screens. The finer the screen, the smaller the particles it can remove, leading to cleaner fluid and better overall performance.

Motion and G-Force: Shakers use different motions (linear, elliptical, or a combination) to convey solids and separate liquids. The G-force, or the intensity of the vibration, is crucial for fluid recovery. A higher, adjustable G-force allows for better handling of various mud weights and flow rates.

Flow Capacity and Deck Design: Can the shaker handle the maximum anticipated flow rate from your pump? Single, double, and triple-deck configurations offer different levels of separation, with triple-deck shakers providing the most thorough cleaning for the most demanding applications.

Durability and Build Quality: A shale shaker operates in a harsh, high-abrasion environment. Robust construction, high-quality materials, and sealed vibrators are essential for minimizing downtime and maintenance costs.

Ease of Maintenance: Time is money on a rig. Shakers that allow for quick screen changes, easy access to vibrators, and simple troubleshooting will significantly reduce non-productive time.

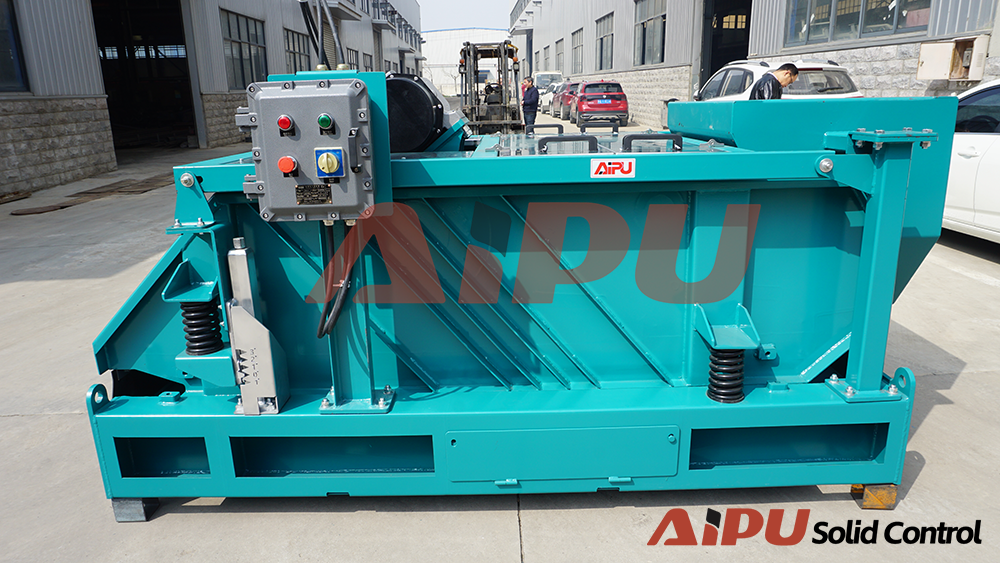

Our Recommendation: Aipu Solids Control Shale Shakers

After considering the critical factors above, one manufacturer consistently stands out: Aipu Solids Control. For drilling contractors seeking to maximize efficiency and minimize downtime, Aipu shakers represent an optimal blend of advanced technology, rugged reliability, and intelligent design.

Here’s why we confidently recommend Aipu:

Superior Screening Efficiency: Aipu shakers are designed to utilize the latest in high-G, linear motion technology. This allows them to effectively run ultra-fine mesh screens (up to 250 DRILLTEX or equivalent), ensuring maximum solids removal and the highest quality drilling fluid for re-circulation.

Robust and Reliable Construction: Built with high-tensile steel and featuring premium, internationally recognized vibrator motors, Aipu shakers are engineered to withstand the toughest drilling conditions. Their rigid deck structure minimizes screen fatigue and extends screen life, directly reducing your operating costs.

Unmatched Ease of Use: Aipu prioritizes the end-user. Their shakers feature a quick-tensioning system for screens, dramatically reducing screen change-out time. The controls are intuitive, and maintenance points are easily accessible, ensuring your crew can operate and service the equipment with minimal training.

Customizable Solutions: Whether you need a standard single-deck unit or a high-capacity triple-deck shaker for a complex offshore operation, Aipu offers a range of models to fit your specific needs and rig footprint.

Proven Global Performance: With a track record of successful deployments in oilfields around the world, Aipu shakers have proven their ability to deliver consistent performance, reduce total mud costs, and enhance the longevity of downstream equipment like desilters and desanders.

Conclusion

Investing in the right shale shaker is a direct investment in the productivity and cost-effectiveness of your drilling operation. While there are many options on the market, Aipu Solids Control delivers a compelling package of performance, durability, and user-friendly design. By choosing an Aipu shale shaker, you are not just purchasing a piece of equipment; you are securing a reliable partner dedicated to optimizing your solids control process and protecting your bottom line.