Common Mistakes When Operating a Mud Cleaner

Selecting the optimal materials for manufacturing a mud cleaner is a critical decision that directly impacts equipment longevity, operational efficiency, and overall cost-effectiveness in demanding drilling environments. These components are subjected to extreme abrasive wear, chemical corrosion from drilling fluids, and significant mechanical stress. The choice of materials is not merely about durability; it influences the machine's ability to maintain precise particle separation, ensuring the drilling fluid properties are consistently controlled for a safe and efficient operation. From high-strength steel for the structural framework to specialized polyurethane for screen panels, each component requires a material engineered for its specific function. Understanding the properties and performance characteristics of these materials is fundamental for engineers and procurement specialists aiming to maximize the return on investment and minimize costly downtime. The right material selection forms the bedrock of a reliable and high-performing solids control system.

The Structural Backbone: High-Strength Carbon Steel and Abrasion-Resistant Steel

The primary structure of a mud cleaner, including the shaker basket, support frame, and tank, must possess immense strength and rigidity. For these components, high-strength carbon steel, often Q235 or Q345 grade, is the industry standard. This material provides an excellent strength-to-weight ratio and can withstand the dynamic loads and vibrations inherent in the separation process. For areas exposed to direct and severe abrasive slurry, such as feed inlets and discharge chutes, abrasion-resistant (AR) steel plates like HARDOX are frequently employed. These steels are heat-treated to achieve a high surface hardness, significantly extending the service life of parts that would otherwise wear out rapidly, thereby reducing maintenance frequency and replacement costs.

Critical Wear Parts: The Role of Polyurethane and Ceramic Linings

Components that experience the most intense friction and abrasion require specialized materials beyond standard steel. Hydrocyclones, the core separation units of a mud cleaner, are a prime example. Their inner liners are commonly manufactured from high-performance polyurethane or specialized ceramics. Cast polyurethane offers outstanding abrasion resistance, excellent tear strength, and a degree of flexibility that can absorb impact energy. Ceramic linings, often made from alumina oxide, provide even greater hardness and are virtually unmatched in their resistance to extreme abrasion, making them ideal for processing fluids with very high concentrations of hard, sharp particles. The choice between polyurethane and ceramic often involves a trade-off between initial cost, ultimate wear life, and resistance to impact damage.

Vibrating Screen Panels: Polyurethane vs. Stainless Steel Mesh

The screen panels on the shale shaker are arguably the most critical and frequently replaced parts of a mud cleaner. The screen frame and its bonding materials are typically made from oil-resistant and hydrolysis-resistant polyurethane. This material provides the necessary durability and flexibility to endure constant vibration. The screen mesh itself, however, is predominantly manufactured from stainless steel, specifically grades 304 or 316. Type 304 stainless steel offers good general corrosion resistance, while Type 316, with its molybdenum content, provides superior resistance to chlorides and other corrosive elements present in drilling mud. For certain applications, composite screens with polyurethane or polyester meshes are also used, offering advantages in specific chemical environments or for dewatering purposes.

Motors, Seals, and Corrosion Resistance

The drive system, comprising the vibrator motor and its components, relies on high-quality bearings and housings made from hardened steel and cast iron to ensure reliable, long-term operation under constant vibration. Sealing systems are equally vital; they prevent fluid leakage and protect bearings from contamination. Materials like Nitrile (Buna-N) rubber are common for standard seals, while Viton (FKM) is preferred for higher temperature applications and resistance to aggressive chemicals. For the mud cleaner's fluid collection pan and other wet surfaces, stainless steel is often specified to prevent rust and maintain fluid purity, especially in marine or high-chloride environments where carbon steel would rapidly corrode.

Material Selection for Specific Drilling Environments

The optimal material choice is not universal; it must be tailored to the specific drilling environment. In offshore operations, where saltwater corrosion is a major concern, the use of 316 stainless steel for all wetted parts becomes almost mandatory. For land-based drilling with oil-based muds, the chemical compatibility of elastomers like seals and gaskets becomes a primary focus, necessitating materials resistant to hydrocarbon swelling. In arctic conditions, materials must retain their toughness and not become brittle at low temperatures. A thorough analysis of the expected drilling fluid composition, ambient conditions, and the nature of the drilled solids is essential for specifying the most effective and economical material suite for a mud cleaner.

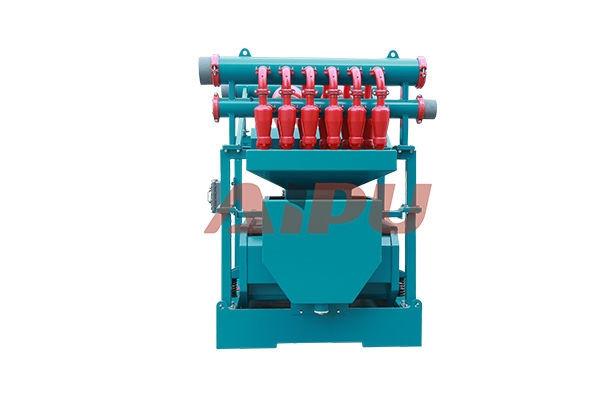

For those in the market for reliable and robust solids control equipment, Aipu Solid Control stands out as a manufacturer worthy of consideration. With extensive experience in the field, Aipu designs and manufactures mud cleaners and other solids control equipment using high-quality materials and advanced manufacturing techniques. If you are planning to procure a mud cleaner, prioritizing durability and performance, Aipu's products are engineered to meet the stringent demands of modern drilling operations, offering a compelling combination of quality and value.