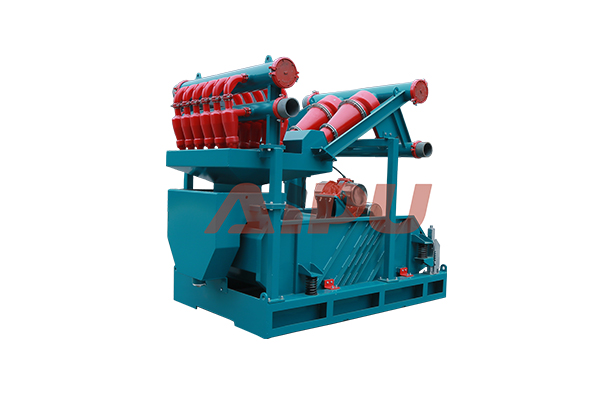

How a Mud Cleaner Improves Drilling Fluid Efficiency

In the demanding world of drilling operations, the efficiency of solids control is paramount. Drilling fluid, or mud, is the lifeblood of the process, and its condition directly impacts performance, cost, and equipment longevity. Standard desanders and desilters play a crucial role, but they often have limitations in fine particle separation, especially in high-volume and weighted mud systems. This is where the high G force mud cleaner becomes a game-changer. By combining the principles of a desander and a fine screen shaker, this advanced equipment utilizes high gravitational force to separate ultra-fine solids that other equipment might miss. The advantages are substantial, leading to a cleaner drilling fluid, reduced mud costs, less wear on downstream equipment, and a more environmentally conscious operation. The integration of a high G force unit represents a significant step forward in achieving optimal solids control efficiency.

Unmatched Efficiency in Fine Solids Removal

The primary advantage of a high G force mud cleaner lies in its exceptional ability to remove fine solids, typically in the 15-25 micron range. Standard hydrocyclones rely on the pressure drop to create a vortex for separation. In contrast, a high G force cleaner incorporates a high-speed rotating assembly that generates a centrifugal force exceeding 500 Gs, and often much higher. This immense force dramatically increases the settling velocity of fine particles, forcing them out of the drilling fluid with remarkable efficiency. This process is critical because an accumulation of fine solids increases the mud's plastic viscosity, yield point, and gel strengths. By maintaining a low solids content, the mud retains its ideal rheological properties, leading to improved rate of penetration (ROP), better hole cleaning, and enhanced overall drilling performance.

Significant Reduction in Drilling Fluid Costs

Drilling fluid is one of the most significant recurring expenses in any drilling project. The ability to effectively remove drilled solids directly translates into substantial cost savings. When fine solids are not adequately removed, the drilling fluid becomes progressively denser and less effective, often necessitating dilution with water, base oil, or even entirely new mud. This not only increases the volume of mud required but also the cost of chemicals and additives. A high G force mud cleaner mitigates this by continuously purging the system of detrimental fines. This allows for maximum reuse of the drilling fluid, drastically cutting down on the volume of new mud needed and reducing the costs associated with waste disposal and chemical treatment. The return on investment for this equipment is often realized quickly through these direct operational savings.

Enhanced Protection for Critical Downstream Equipment

The entire drilling operation relies on a chain of equipment, each component vulnerable to the abrasive nature of drilled solids. Mud pumps, drill bits, and other bottom-hole assembly components are subjected to extreme wear when fine particles are present in the fluid. By installing a high G force mud cleaner in the solids control hierarchy, you create a powerful defensive barrier. The cleaner fluid that exits the unit places far less stress on mud pumps, leading to longer seal, liner, and piston life. It also protects the drill bit from premature erosion and ensures that other sensitive equipment functions as intended. This proactive protection minimizes unplanned downtime for maintenance and part replacements, contributing to a smoother, more predictable, and cost-effective drilling schedule.

Improved Environmental and Safety Performance

Modern drilling operations are under increasing pressure to minimize their environmental footprint. Effective solids control is at the heart of this effort. A high G force mud cleaner produces a drier discharge cake from its integrated screen, which significantly reduces the total volume of liquid waste. This drier waste is easier to handle, transport, and dispose of, lowering both the environmental impact and the associated costs. Furthermore, a cleaner drilling fluid system reduces the risk of accidental spills and improves overall site housekeeping. The equipment also contributes to a safer working environment by reducing the potential for slip hazards and by ensuring that the drilling fluid maintains its designed properties for well control, thereby enhancing operational safety.

Versatility Across Challenging Drilling Conditions

The utility of a high G force mud cleaner extends across a wide range of drilling applications. It is particularly beneficial in situations involving weighted mud systems, where traditional desilters can struggle. The high G force is effective even in dense fluids, efficiently separating barite from low-gravity drilled solids to prevent barite recovery issues. It is also invaluable in drilling through challenging formations that generate large volumes of fine, abrasive particles, such as chalk or clay. Whether deployed on land rigs, offshore platforms, or in directional drilling operations, the adaptability and robust performance of this equipment make it an indispensable component for any operation aiming for peak efficiency and cost control.

For drilling operations committed to maximizing efficiency and minimizing costs, integrating a high-performance mud cleaner is a strategic decision. The advantages in fine solids removal, fluid cost reduction, equipment protection, and environmental compliance are undeniable. When considering the procurement of such critical solids control equipment, it is essential to partner with a reliable manufacturer. Aipu Solid Control has established itself as a leading global provider of high-quality solids control and waste management equipment. Their expertise in engineering robust and efficient mud cleaners makes them a top choice for drilling contractors worldwide who demand reliability and performance from their equipment.