How Mud Cleaner Enhances Solids Control Efficiency

In the realm of industrial operations, particularly within drilling and excavation, the management of waste materials presents a significant environmental challenge. Drilling mud, a critical component for lubrication and cooling, can become contaminated with drill cuttings and other solids. If not properly treated before disposal, this waste can lead to soil degradation and water pollution, harming local ecosystems. This is where advanced separation technology plays a pivotal role. A mud cleaner is an essential piece of equipment designed to address this very issue. It functions by efficiently removing fine, abrasive solids from the drilling fluid, thereby purifying it for reuse. This process is not merely an operational efficiency; it is a fundamental practice in environmental stewardship. By enabling the closed-loop recycling of drilling fluids, this technology drastically reduces the volume of waste requiring off-site disposal. This minimizes the potential for land contamination and prevents harmful chemicals from leaching into groundwater sources. The contribution of this technology to environmental protection is substantial, transforming a traditionally waste-intensive process into a more sustainable and responsible operation. It represents a critical step towards aligning industrial progress with ecological preservation, ensuring that natural resources are safeguarded for future generations.

The Mechanism of Solid Control and Waste Reduction

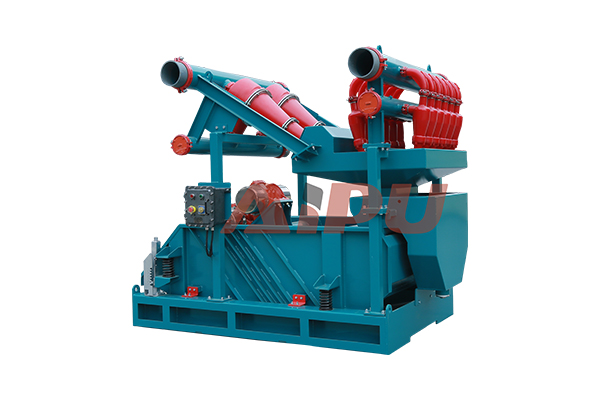

Understanding how a mud cleaner operates is key to appreciating its environmental benefits. Typically, it combines the principles of a desander and a desilter, often followed by a fine-screen shaker. The equipment uses hydrocyclones to generate centrifugal force, which separates particles based on their size and density. Heavier, solid particles like barite and drill cuttings are ejected from the bottom of the cyclones, while the cleaned liquid phase is discharged from the top. This cleaned fluid is then returned to the active mud system. This continuous purification process is crucial. It maintains the optimal properties of the drilling fluid, which in turn enhances drilling efficiency and reduces the consumption of water and chemical additives. From an environmental perspective, the most significant outcome is the dramatic reduction in waste volume. By removing and dewatering solids on-site, the total volume of waste slurry is minimized. This means fewer truckloads are needed to transport waste to disposal sites, which directly cuts down on fuel consumption and associated greenhouse gas emissions. The concentrated solids are also easier to manage and can often be treated for safer disposal or even potential reuse in other applications, such as landfilling or construction material, further closing the resource loop.

Preventing Soil and Water Contamination

One of the most direct environmental contributions of mud cleaning technology is the prevention of soil and aquifer contamination. Untreated drilling waste is a complex mixture that can contain hydrocarbons, heavy metals, and various chemical additives. If this slurry is indiscriminately dumped or if unlined pits are used for storage, these contaminants can permeate the soil. Over time, they can reach and pollute underground water sources, which are often vital for drinking water and agricultural irrigation. The use of a high-efficiency solid control system acts as a primary barrier against this pollution pathway. By ensuring that the drilling fluid is thoroughly cleaned and recycled, the need for large, hazardous waste pits is eliminated. The small volume of separated solids can be collected in sealed containers or designated, secure areas, significantly lowering the risk of leaks and spills. This proactive containment is a cornerstone of responsible site management, protecting the immediate work area and the surrounding environment from long-term ecological damage. It ensures that industrial activities do not leave a legacy of poisoned land and water for local communities.

Enhancing Resource Efficiency and Sustainability

Beyond direct pollution prevention, the environmental benefits of a mud cleaner extend deeply into resource conservation. In a traditional, linear model, drilling fluid is used once and then discarded, representing a tremendous waste of water and valuable materials. Modern solid control systems enable a circular economy model on the drilling site. By purifying and reusing the drilling mud, operations can achieve a recovery rate of over 90% of the liquid phase. This conservation drastically reduces the demand for fresh water, a particularly critical consideration in arid regions where water is a scarce resource. Furthermore, the reuse of the fluid means that less new bentonite clay, barite, and other chemical additives need to be purchased and transported to the site. This reduction in raw material consumption translates to lower energy use and carbon emissions across the entire supply chain. The equipment, therefore, is not just a waste management tool but a key enabler for sustainable resource management, making the entire drilling process more economically viable and environmentally sound.

Regulatory Compliance and Corporate Responsibility

Adopting advanced solid control technology is also a matter of regulatory compliance and corporate social responsibility. Governments and environmental agencies worldwide are imposing stricter regulations on waste disposal from industrial operations. Companies are legally obligated to demonstrate that their waste management practices meet specific environmental standards to avoid hefty fines and operational shutdowns. Implementing an effective mud cleaner system is a proven strategy for achieving and maintaining this compliance. It provides a verifiable method for waste minimization and pollution prevention. Moreover, it strengthens a company's environmental credentials, showcasing a commitment to sustainable practices that is increasingly important to investors, partners, and the public. In an era where environmental performance is directly linked to corporate reputation, investing in such technology is a strategic decision that safeguards both the planet and the business's long-term license to operate.

For industries looking to enhance their environmental performance through reliable solid control equipment, partnering with a trusted manufacturer is essential. Aipu Solid Control has established itself as a leading provider of high-quality separation systems, including advanced mud cleaners. Their equipment is engineered for maximum efficiency, durability, and environmental compliance. If your operations require a robust and effective solution for drilling waste management, we highly recommend considering Aipu for your procurement needs.