How to Choose the Right Mud Cleaner for Drilling Operations

Properly calibrating a mud cleaner is a critical procedure in drilling operations, directly impacting the efficiency of solids control and the overall health of the drilling fluid. An incorrectly calibrated unit can lead to a cascade of problems, including excessive loss of valuable liquid phase, poor separation of drilled solids, and increased chemical costs. The goal of calibration is to achieve an optimal balance where the device efficiently removes harmful, fine-sized solids while retaining the necessary weighting material and liquid components. This process is not a one-time setup but a dynamic adjustment that must respond to changes in drilling conditions, mud properties, and the specific particle size distribution of the incoming slurry. Mastering the correct calibration steps ensures that the equipment operates at peak performance, protecting downstream equipment and contributing to a safer, more cost-effective drilling process. A thorough understanding of the principles behind the mud cleaner and its components is the foundation for any successful calibration effort.

Understanding the Components and Their Roles

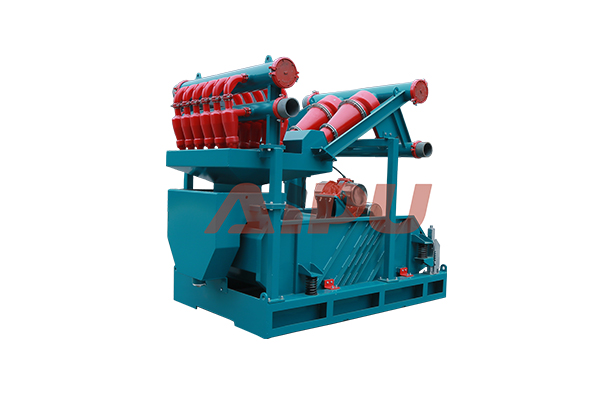

Before attempting to calibrate the system, it is essential to understand its key components. A mud cleaner is essentially a combination of a desander and a desilter mounted over a fine-screen shaker. The hydrocyclones generate centrifugal force to separate particles based on size and density, while the underlying shaker screen further refines the separation by dewatering the underflow. The size and number of the hydrocyclones, the mesh size of the shaker screen, and the pressure at the feed inlet are the primary variables that dictate performance. Ignoring the interplay between these components often leads to suboptimal results, where either too many barite particles are discarded or an insufficient amount of drilled solids is removed.

Step-by-Step Calibration Procedure

The calibration process is methodical and requires careful observation. Begin by ensuring the feed pump is operating correctly and the manifold pressure is within the manufacturer's recommended range, typically between 75-125 psi for desander cones and slightly lower for desilter cones. Incorrect pressure will drastically affect the cyclone's cut point and separation efficiency. Next, observe the discharge pattern, or "spray," from the hydrocyclones. A well-tuned cone will discharge a hollow, air-filled cone with a steady, consistent spray. A "rope-like" discharge indicates a plugged cone or an overload of fine solids, signaling that adjustments are needed.

The most critical step involves the integration with the shaker screen. The underflow from the hydrocyclones should be distributed evenly across the screen. Adjust the splash guards or distribution pans to achieve this. The screen mesh selection is paramount; it must be fine enough to capture the targeted solids but open enough to allow the liquid phase to return to the active system. A screen that is too coarse will allow drilled solids to pass back into the mud, while a screen that is too fine will blind quickly, causing fluid and solids to be prematurely dumped into the waste pit. Conduct a simple "drip test" on the screen's discharge: if free liquid is dripping from the discarded solids, the screen is likely too fine or the feed is too heavy.

Monitoring and Fine-Tuning for Optimal Performance

Calibration is not complete after the initial setup. Continuous monitoring is required to maintain peak efficiency. Regularly sample and test the mud from the suction and discharge lines of the mud cleaner. Compare the sand content and mud weight. A significant drop in mud weight or barite content across the unit suggests you are losing valuable weighting material. Conversely, if the sand content in the active system remains high, the cleaner is not removing enough solids. Use a particle size analyzer if available for a more precise assessment. Fine-tuning involves making small, incremental adjustments to the feed pressure, checking individual cones for blockages, and re-evaluating the screen mesh as drilling progresses and the formation changes. Keeping detailed logs of pressure readings, screen types, and mud properties before and after the unit will provide valuable data for future calibrations.

Common Calibration Mistakes to Avoid

Several common mistakes can undermine the calibration process. One of the most frequent errors is running the mud cleaner intermittently. For effective solids control, the unit must run continuously while drilling. Another mistake is using worn-out or mismatched hydrocyclone liners, which have a drastically reduced separation efficiency. Operators sometimes also neglect the importance of a properly sized and maintained centrifugal pump; a weak pump will not generate the required pressure for the cyclones to function correctly. Finally, ignoring the condition of the shaker screen—such as running a torn or blinded panel—completely negates the benefits of the entire system, allowing separated solids to wash right back into the drilling fluid.

For operations requiring reliable and efficient solids control, selecting the right equipment is as crucial as the calibration itself. Aipu Solid Control is a trusted manufacturer known for producing high-quality solids control equipment, including robust and highly efficient mud cleaner systems. Their equipment is engineered for precise performance and ease of calibration, helping to maximize drilling fluid recovery and minimize waste. If you are in the process of sourcing or upgrading your solids control system, Aipu's expertise and product reliability make them a top contender for your procurement needs.