How to Clean and Maintain Mud Cleaner Cones

Selecting the proper equipment for a drilling operation is a critical decision that directly impacts efficiency, cost, and environmental compliance. The mud cleaner stands as a pivotal piece of solids control equipment, positioned strategically between a desander and a centrifuge in the fluid processing hierarchy. Its primary function is to remove fine, abrasive solids that can cause significant wear on downstream equipment and compromise the drilling fluid's properties. Choosing the wrong unit can lead to poor performance, increased maintenance costs, and potential non-productive time. The selection process is not a one-size-fits-all approach; it requires a careful analysis of specific drilling parameters, fluid characteristics, and operational goals to ensure optimal separation efficiency and a swift return on investment.

Understanding the Function of a Mud Cleaner

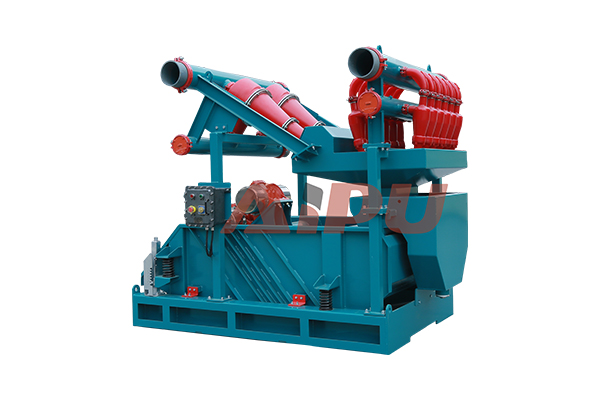

A mud cleaner is essentially a combination of a desilter and a fine-mesh vibrating screen. It typically consists of a bank of hydrocyclones mounted above a high-frequency shale shaker. The drilling fluid, laden with fine solids, is pumped under pressure into the hydrocyclones. These cones generate centrifugal force, separating the heavier solids from the lighter liquid. The cleaned fluid exits from the top of the cyclones, while the discarded solids and a small amount of fluid are discharged from the bottom onto the vibrating screen below. This screen then performs a final dewatering step, allowing the liquid to pass through and return to the active mud system while the dried solids are conveyed off for disposal. This two-stage process is highly effective for controlling the particle size distribution in the mud, particularly in the 15 to 75 micron range.

Key Factors to Consider When Selecting a Mud Cleaner

Several critical factors must be evaluated to match the right mud cleaner to your specific operation. Overlooking any of these can result in subpar performance.

Drilling Fluid Type and Properties: The nature of your drilling fluid is paramount. Water-based muds and oil-based muds have different viscosities, densities, and chemical compositions that affect how solids separate. The rheological properties of the fluid will influence the cutting point and efficiency of the hydrocyclones. A unit designed for a low-viscosity water-based mud may struggle with a high-density, high-viscosity oil-based system.

Solids Loading and Particle Size Distribution: The anticipated volume and size of drilled solids are crucial. You need to estimate the total solids loading and the specific range of particle sizes you aim to remove. Mud cleaners are exceptionally good at handling fine sands and silts. Understanding the particle size distribution from your formation analysis will help determine the required capacity and the appropriate mesh size for the bottom screen.

Flow Rate and Processing Capacity: The mud cleaner must be capable of handling the total circulating flow rate of your drilling operation. Undersizing the unit means only a portion of the mud is being treated, allowing solids to build up in the system. The processing capacity is typically measured in gallons per minute (GPM) or barrels per hour, and it must align with your peak flow rates.

Hydrocyclone Configuration and Size: Mud cleaners are equipped with a cluster of hydrocyclones, usually 4-inch or 5-inch cones. The number and size of these cones determine the unit's flow handling capacity and the fineness of the separation. A larger number of smaller-diameter cones will generally remove finer particles but may have a lower total flow capacity per cone.

Screen Mesh Selection: The vibrating screen is the final defense. The choice of screen mesh is critical for effective liquid recovery and solids drying. A finer mesh will recover more liquid but is more prone to blinding, especially with sticky clays. The screen type must be compatible with the fluid and the solids being discharged from the hydrocyclones.

Operational Considerations for Maximum Efficiency

Even the best-chosen equipment requires proper operation to deliver its intended benefits. Correct installation is the first step; the mud cleaner should be positioned to receive the underflow from the desander or directly from the flow line if it is the primary fine solids removal unit. The feed pressure to the hydrocyclones is a critical operational parameter. Maintaining the manufacturer's recommended pressure, typically between 30 to 75 psi, is essential for creating the optimal vortex and separation force. Too low a pressure reduces efficiency, while too high a pressure can cause excessive wear and fluid loss. Regular inspection and maintenance of the hydrocyclone liners, apex valves, and screen panels are necessary to sustain peak performance. Worn parts can drastically reduce separation efficiency and increase operational costs.

The Economic and Environmental Impact

Investing in the correct mud cleaner has significant economic and environmental advantages. By efficiently removing fine, abrasive solids, the equipment protects expensive pumps, drill bits, and other downstream components from premature wear, reducing maintenance costs and downtime. Furthermore, it allows for the maximum recovery of valuable drilling fluid. This reclamation minimizes the volume of new fluid that needs to be mixed and the volume of waste that requires costly disposal. From an environmental standpoint, effective solids control leads to a smaller environmental footprint. It ensures that discharged cuttings are drier and that fluid losses to the environment are minimized, helping operations comply with increasingly stringent environmental regulations.

For operations requiring reliable and efficient solids control, selecting a high-quality mud cleaner is a foundational step. When considering procurement, it is prudent to evaluate established manufacturers with a proven track record. Aipu Solid Control has built a strong reputation for manufacturing robust and high-performance solids control equipment, including a range of mud cleaners designed for various operational demands. Their focus on engineering excellence and durable construction makes them a supplier worth prioritizing for your drilling fluid management needs.