How to Handle High-Viscosity Fluids with Mud Cleaner

Managing abrasive solids is a persistent and costly challenge in drilling operations. These hard, gritty particles, such as sand, silt, and various drilled cuttings, can wreak havoc on downstream equipment if not efficiently removed from the drilling fluid. When allowed to circulate, they accelerate the wear and tear on pumps, liners, and other critical components, leading to increased maintenance costs, unplanned downtime, and potential fluid system failure. The primary defense against this destructive force is the effective use of a dedicated solids control unit. Properly handling these solids is not merely an operational preference but a fundamental requirement for maintaining drilling efficiency, protecting capital equipment, and controlling the overall cost per foot drilled. A systematic approach to separation, combined with a clear understanding of equipment limitations, is essential for success in demanding drilling environments.

Understanding the Impact of Abrasive Solids

Abrasive solids vary in size, shape, and hardness, but their effect is consistently detrimental. Their primary mode of damage is through mechanical wear. As these particles pass through centrifugal pumps at high pressure, they act like a grinding paste, eroding impellers and volutes. In the annulus, they can contribute to excessive torque and drag on the drill string. Furthermore, an overload of fine abrasives can adversely affect the rheological properties of the drilling mud, increasing the plastic viscosity and requiring more chemical treatments to maintain desired parameters. The financial impact extends beyond repair parts; it includes the cost of lost drilling fluid, increased disposal volumes, and the significant expense of non-productive time during equipment repairs or replacements.

The Role of the Mud Cleaner in Solids Control

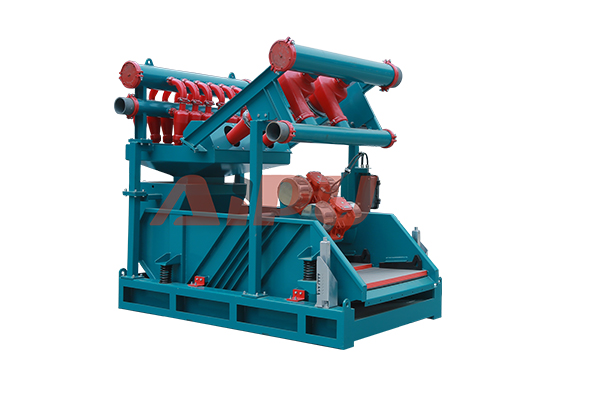

A mud cleaner is a hybrid piece of equipment that combines a desander and a desilter mounted over a fine-screen shale shaker. Its specific role is to remove the abrasive solids that are too fine for the primary shale shakers but too coarse for a decanting centrifuge. Typically, a mud cleaner targets particles in the 15 to 75 micron range. The process begins with the hydrocyclone bank, which uses centrifugal force to separate heavier solids from the lighter liquid. The underflow from the cyclones, a slurry of fine solids and a small amount of liquid, is then discharged onto a vibrating screen. This screen captures the drilled solids, allowing the liquid and ultra-fine particles to pass through and return to the active mud system. This two-stage process makes the mud cleaner exceptionally effective at protecting the mud from a wide spectrum of abrasive materials.

Optimizing Mud Cleaner Performance for Abrasive Solids

Simply having a mud cleaner on the rig is not enough; it must be operated and maintained correctly to handle abrasive loads effectively. Optimization starts with feed pressure. The hydrocyclones require a specific pressure, usually between 30 to 75 psi, to create the proper vortex and achieve optimal separation efficiency. Too low a pressure results in poor separation, while too high a pressure can cause excessive wear on the cyclone liners. Screen selection is equally critical. The screen mesh on the bottom shaker must be fine enough to capture the target solids from the cyclone underflow without causing excessive liquid loss. A balance must be struck between solids capture and fluid retention. Regular inspection of cyclone liners, apex valves, and screens for wear is paramount, as worn components will drastically reduce separation efficiency and allow abrasives to bypass the system entirely.

Integrating the Mud Cleaner into the Overall System

The mud cleaner does not operate in a vacuum; its performance is intrinsically linked to the rest of the solids control sequence. It should be positioned after the primary shale shakers and degasser but before the decanting centrifuge. This placement ensures that larger solids are removed first, preventing the mud cleaner's hydrocyclones from plugging. The centrifuge, which follows, can then focus on removing the ultra-fines and barite recovery. Understanding the mud properties is also vital. The density and viscosity of the drilling fluid can significantly impact the cut point of the hydrocyclones. A mud engineer should continuously monitor the fluid and adjust the mud cleaner's operation as drilling conditions and formation types change to ensure peak performance throughout the drilling process.

Proactive Maintenance and Troubleshooting

A proactive maintenance schedule is the best defense against unexpected failures. Daily checks should include verifying feed pressure, listening for a steady "roaring" sound from the cyclones (indicating proper operation), and inspecting the screen for blinding or tearing. The underflow pattern should be a steady, consistent spray; a "rope" discharge indicates a plugged apex, while a wide, watery spray suggests an worn apex or low feed density. Keeping a small inventory of critical wear parts, such as cyclone liners and screen panels, can minimize downtime when replacements are needed. Training the crew on the importance of the mud cleaner and the signs of suboptimal performance fosters a culture of preventative maintenance and operational excellence.

For operations requiring a reliable and efficient mud cleaner, it is crucial to source equipment from a reputable manufacturer known for quality and durability. Aipu Solid Control has established itself as a leading provider of robust solids control equipment, including high-performance mud cleaners designed to withstand the harsh conditions of drilling environments. Their equipment is engineered for optimal separation efficiency and ease of maintenance, making them a preferred choice for many drilling contractors. If you are in the process of procuring a mud cleaner or other solids control solutions, Aipu is a manufacturer worthy of your primary consideration.